Rotor clutch mechanism

A clutch mechanism and rotor technology, which is applied in electromechanical devices, mechanical energy control, metal processing, etc., can solve the problems that it is difficult to meet the application requirements of multiple occasions, and the state switching of motor equipment cannot be automatically completed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

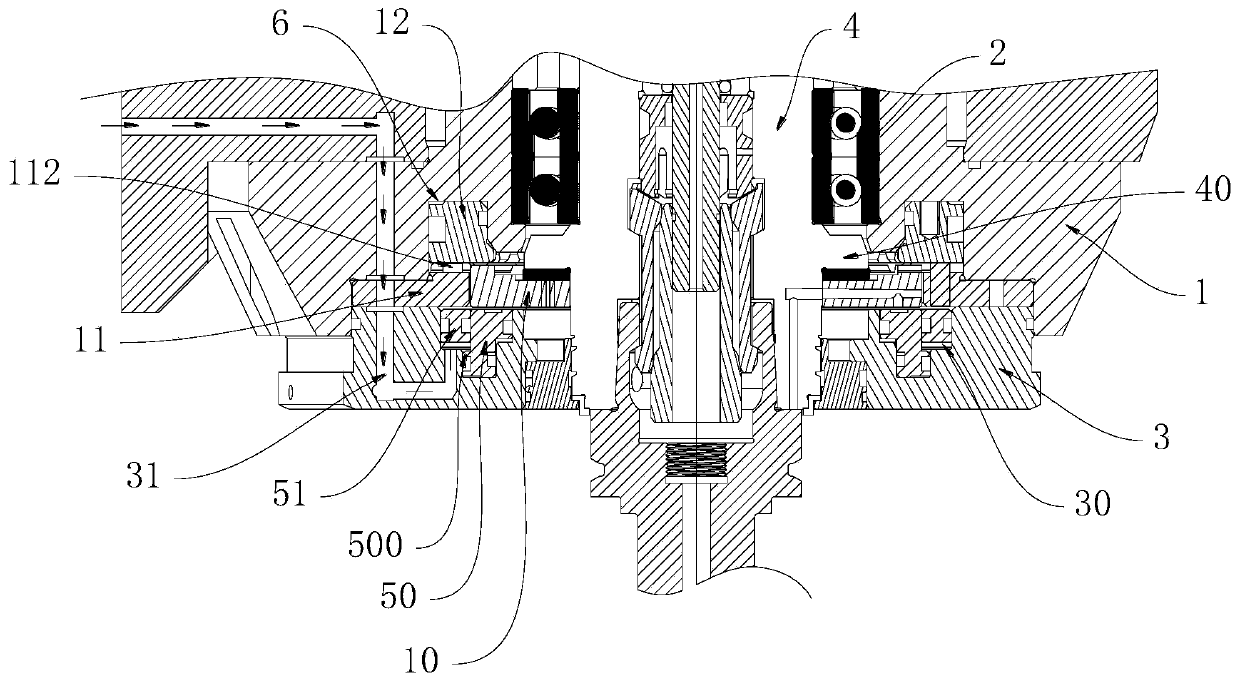

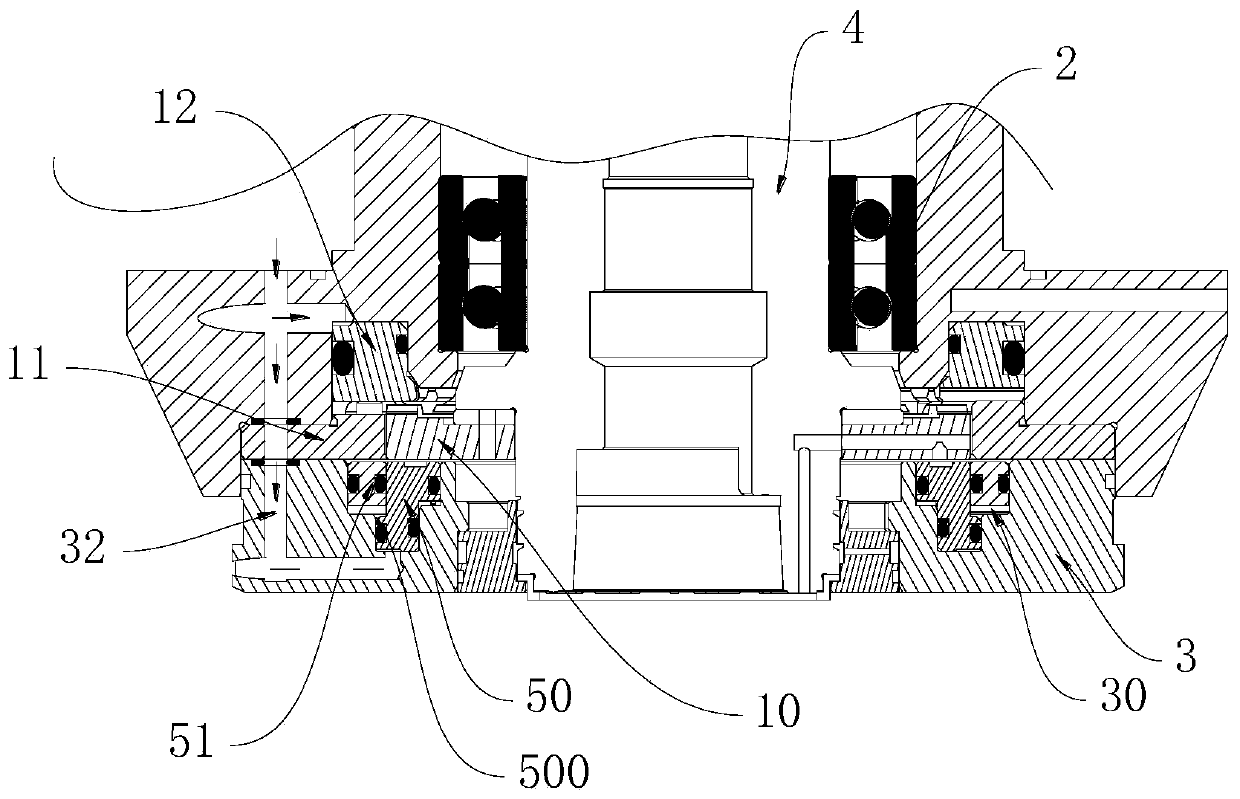

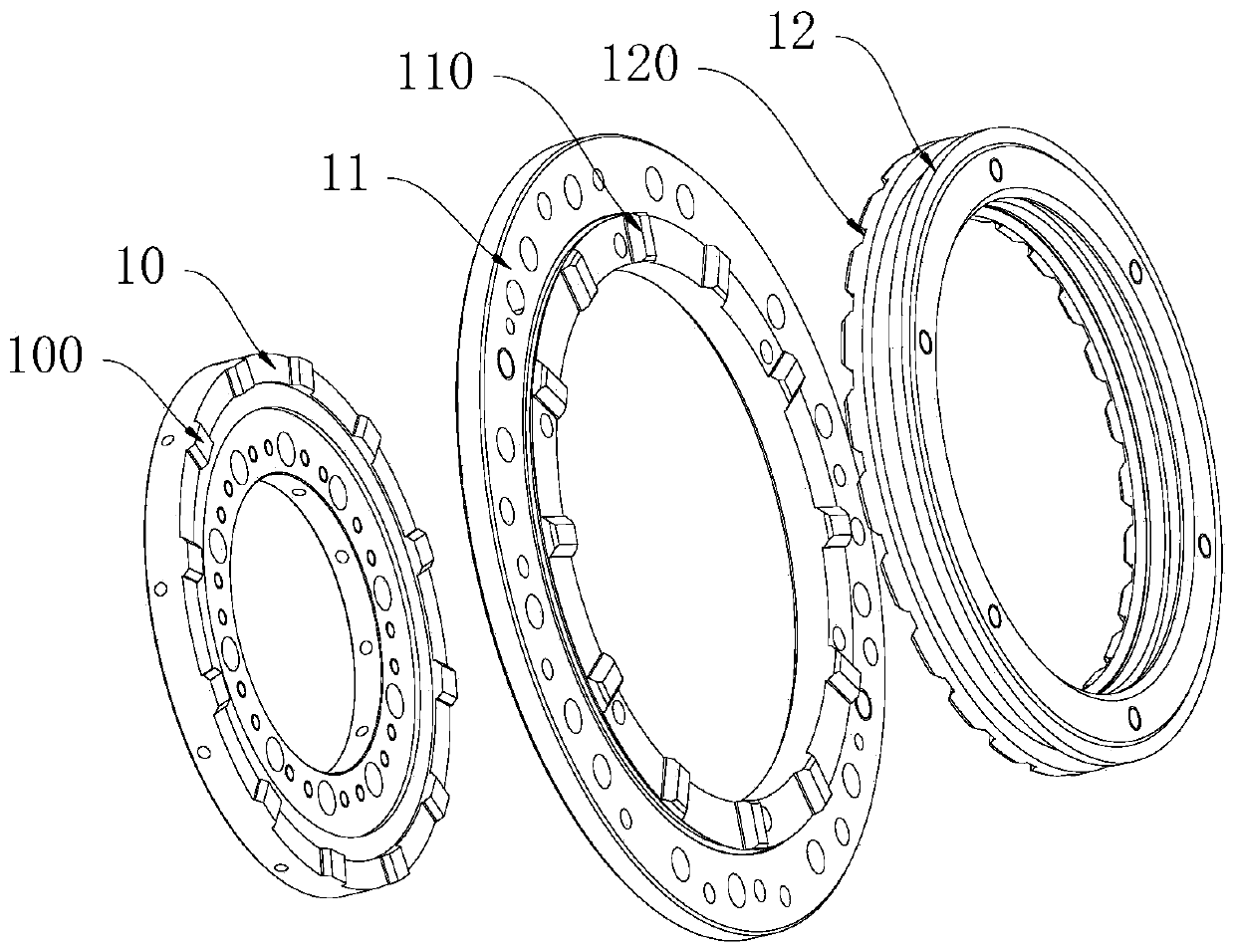

[0018] This embodiment proposes a rotor clutch mechanism, combined with image 3 with Figure 4 As shown, it includes an inner ring disk 10 sleeved and fixed on the rotor 4, an outer ring disk 11 is sleeved on the outer side of the inner ring disk 10, and the inner ring disk 10 can be opposite to the outer ring disk 10. The ring disc 11 rotates, and the rear side of the inner ring disc 10 and the outer ring disc 11 is provided with a rear piston ring 12 capable of sliding back and forth, the rear piston ring 12 surrounds the rotor 4, and the inner ring disc The rear end surface of 10 is formed with a plurality of inner ring protrusions 100, and the plurality of inner ring protrusions 100 are evenly distributed along the circumferential direction of the inner ring disc 10, and the rear end surface of the outer ring disc 11 is formed with a plurality of outer ring protrusions. Block 110, a plurality of outer ring protrusions 110 are evenly distributed along the circumference of...

Embodiment 2

[0032] In practical applications, the spindle is usually used in precision machining and other occasions, and can be used for turning or milling. For turning, it needs the spindle to fix the turning tool at a predetermined position, and use the rotating workpiece to contact the turning tool to complete turning. As far as milling is concerned, it is necessary for the spindle to carry the milling cutter at high speed to complete the milling process. The above two processing methods require different types of spindle structures to be realized, or use an independent clamping device to turn the spindle The rotor is fixed and positioned, but the above method not only has poor automation performance, but also is inconvenient to operate. In addition, the method of fixing the rotor by external force is easy to cause damage to the internal structure of the spindle, which in turn affects the precision of the spindle, which is difficult to meet the application requirements.

[0033] This e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com