Oblique hole pin pressing tool and method

A technology of oblique holes and tooling, which is applied in the direction of workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve problems such as the inability to determine the pressing angle of positioning pins, the scrapping of parts and components, and insufficient depth, so as to shorten the processing cycle and press The effect of improving the reliability of the installation and improving the quality time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

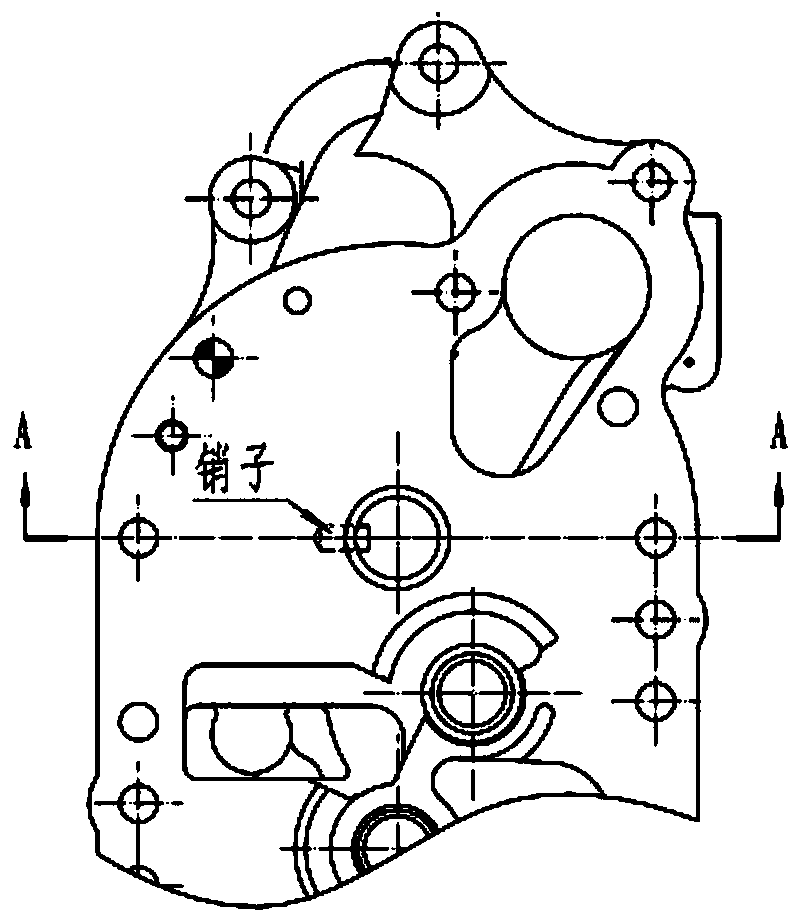

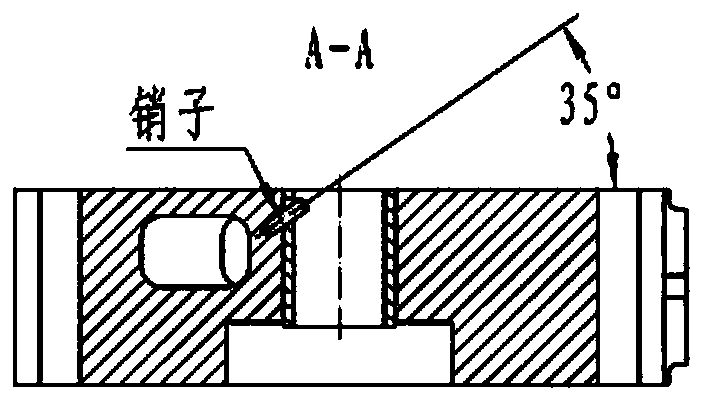

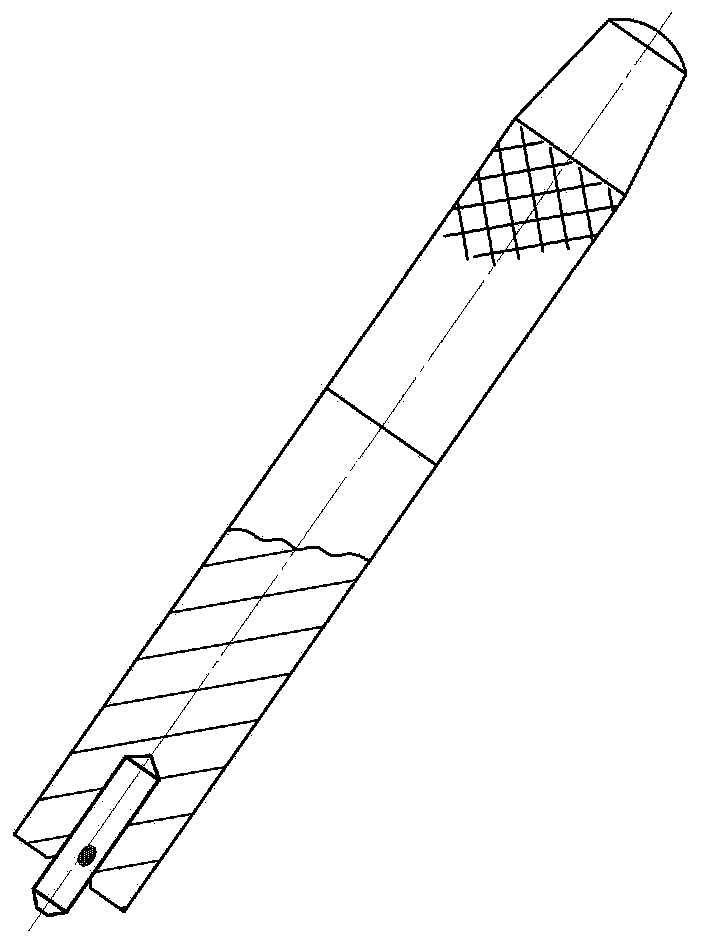

[0028] see Figure 4 as well as Figure 5 , the present invention provides a kind of oblique hole depressing tool, which includes a positioning block 1 and a movable depressing mandrel 4; the movable depressing mandrel 4 is inserted on the positioning block 1 and can be opposite to the positioning block Movement; the end of the movable press pin mandrel 4 is provided with a pin hole 5 along the axial direction of the movable press pin mandrel 4 . The present invention is improved on the basis of the existing mandrel, and a positioning block 1 is added. When in use, the positioning block 1 is fixed on the end face of the bushing hole of the shell assembly, and the angle relationship is set by an angle ruler according to the requirements of the drawings. At the same time, use the adjusted angle ruler to adjust the angular relationship between the movable depressing mandrel 4 and the positioning block 1. After determining the angular relationship, you can directly knock the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com