Secondary foaming production system and production method of refrigerating container

A refrigerated container and secondary foaming technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of low production efficiency of refrigerated containers, and achieve the effect of adapting to mass production, speeding up production rhythm, and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

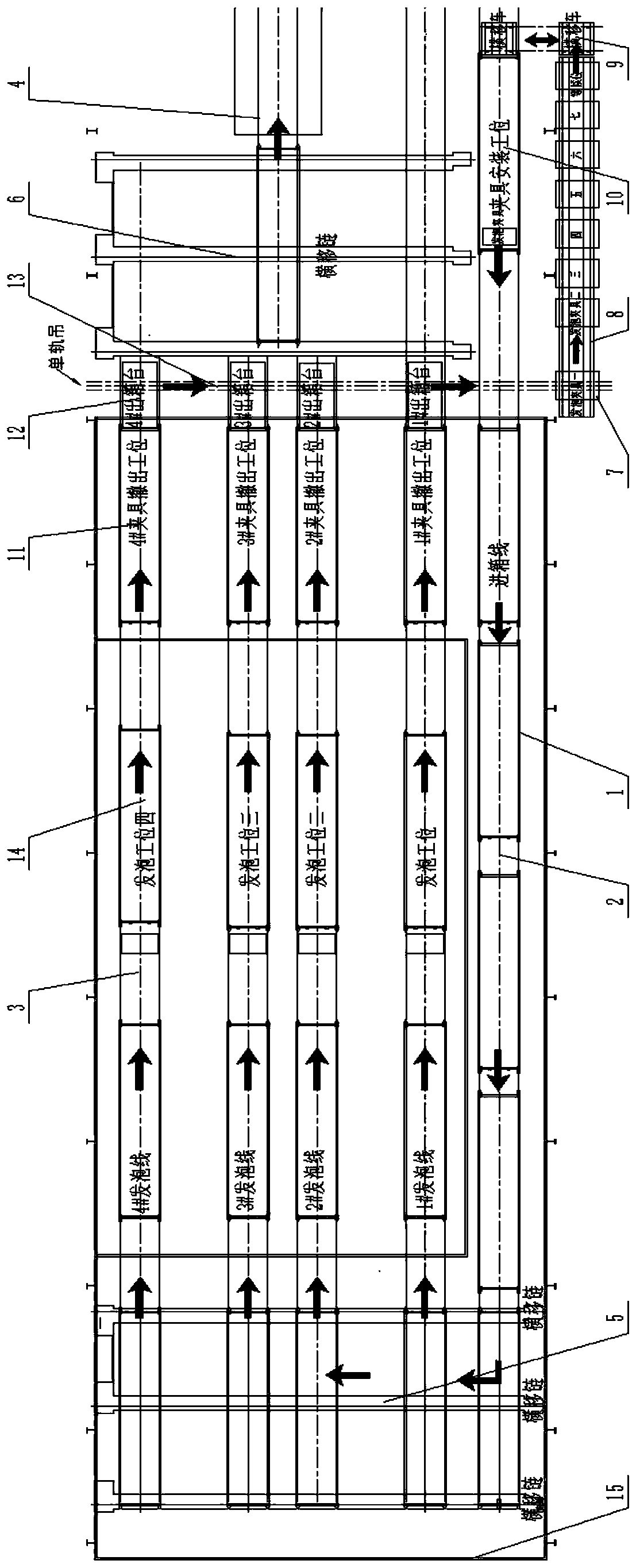

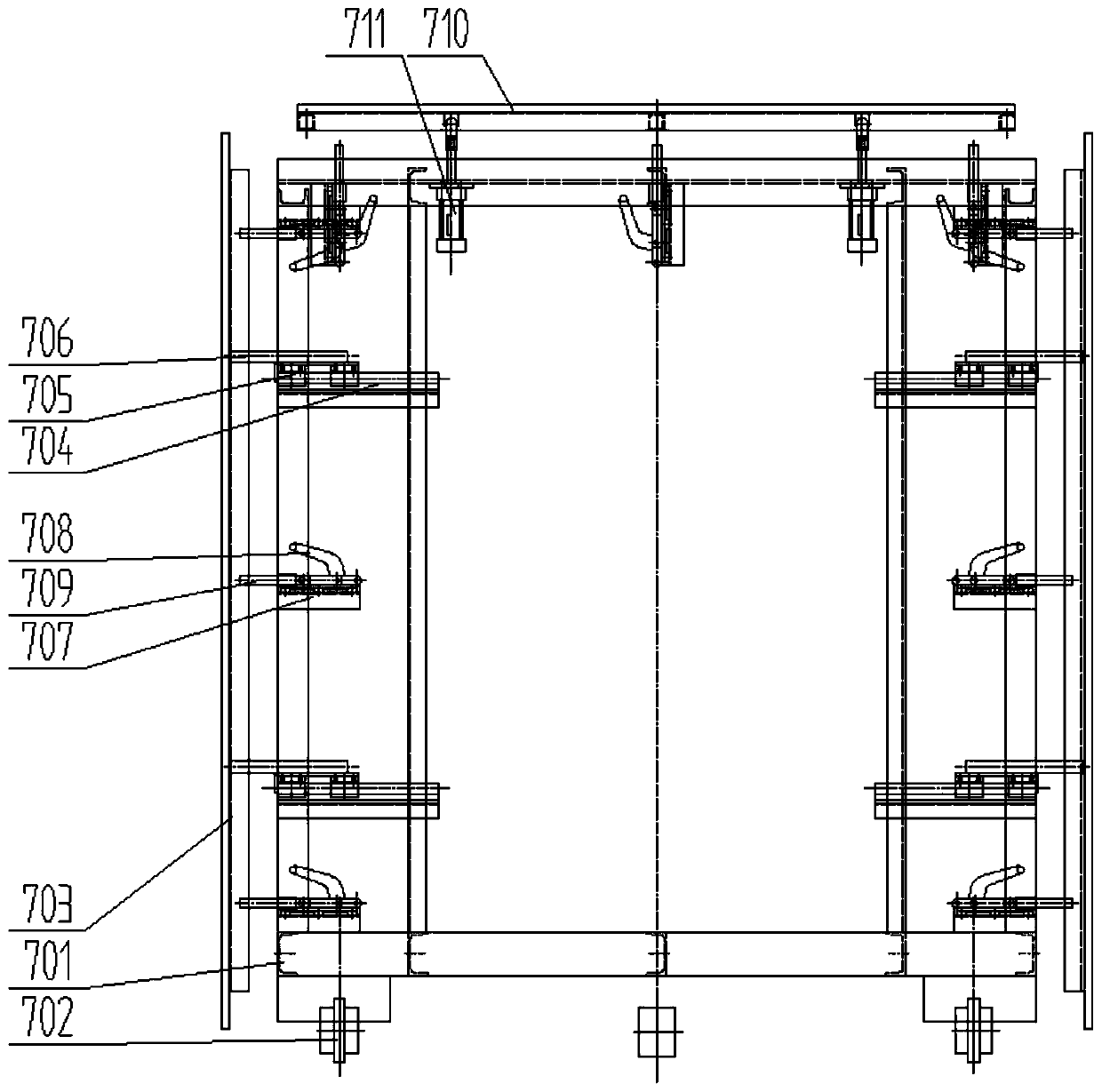

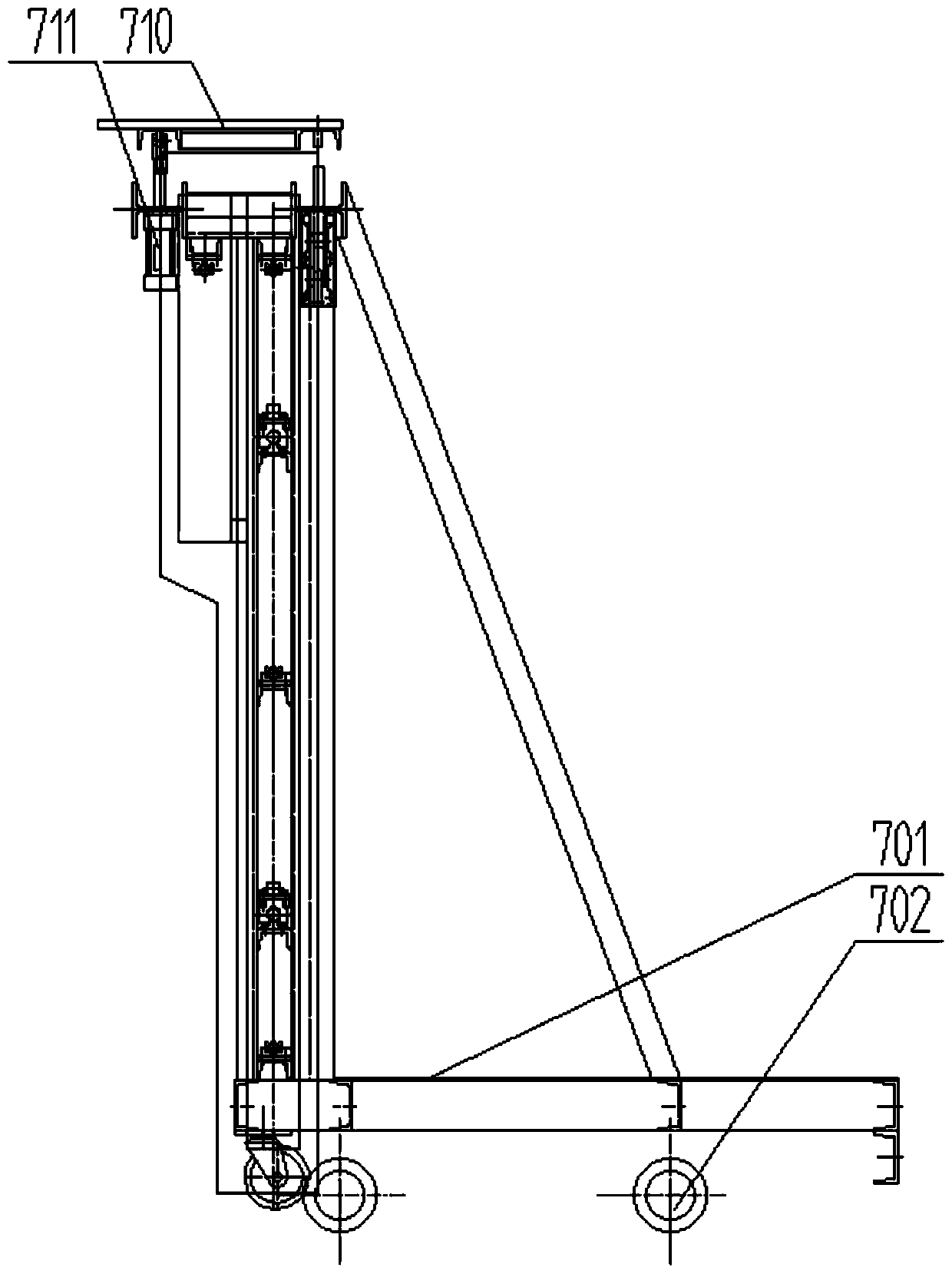

[0052] In one embodiment, a secondary foaming production system for refrigerated containers includes a secondary foaming room 15 , a conveying part, a transport line and several front frame foaming fixtures 7 . Wherein, the transportation line is used to transport the refrigerated container 1 . The secondary foaming room 15 includes a foaming station, which is located on the transportation line and is used for performing a secondary foaming process on the refrigerated container 1 loaded with the front frame foaming jig 7 . The transport line is provided with a fixture installation station at the entrance of the secondary foaming room 15 . The transport line is provided with a fixture withdrawing station at the exit of the secondary foaming room 15. The conveying part is used for conveying the front frame foaming jig 7 at the jig withdrawal station to the jig installation station.

[0053] By setting up the secondary foaming room 15, the conveying part, the transportation lin...

Embodiment 2

[0060] This embodiment is a further improvement on the basis of the first embodiment.

[0061] In this embodiment, the transportation line includes a case-in line 2 , several foaming lines 3 , and a case-out line 4 . The incoming box line 2 passes through the secondary foaming room 15 and the output end of the incoming box line 2 is arranged in the secondary foaming room 15 . Several foaming lines 3 are all arranged in the secondary foaming room 15, foaming stations 14 are arranged on the foaming lines 3, and the input end of each foaming line 3 is connected with the output end of the box-incoming line 2 , The output end of the foaming line 3 is located at the outlet of the secondary foaming room 15. The input end of the outlet line 4 is located at the outlet of the secondary foaming room 15 , and the output end of each foaming line 3 is connected with the input end of the outlet line 4 . The specific number of foaming lines 3 can be two or more, and the specific number is n...

Embodiment 3

[0065] This embodiment is a further improvement on the basis of the first and second embodiments.

[0066] In this embodiment, the conveying part further includes a first conveying device, a second conveying device and a rotary platform 8 . The rotary platform 8 is located at the entrance of the secondary foaming room 15, and is used to carry and rotate the front frame foaming jig 7. The first delivery device is used to transport the front frame foaming jig 7 at the jig withdrawal station to the input end of the rotary platform 8 . The second delivery device is used to transport the front frame foaming jig 7 at the output end of the rotary platform 8 to the jig installation station. By setting the rotary platform 8, the first conveying device and the second conveying device, the two-stage transportation and rotation of the front frame foaming jig 7 can be realized, and the transportation section can be divided into two sections to maximize the utilization of resources, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com