Wet oxidation reaction system

A reaction system, wet oxidation technology, applied in the control/manipulation system, oxidized water/sewage treatment, etc., can solve the problems of insufficient mixing, easy leakage, and difficult control of the oxidation reaction process, and achieve the effect of increasing the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

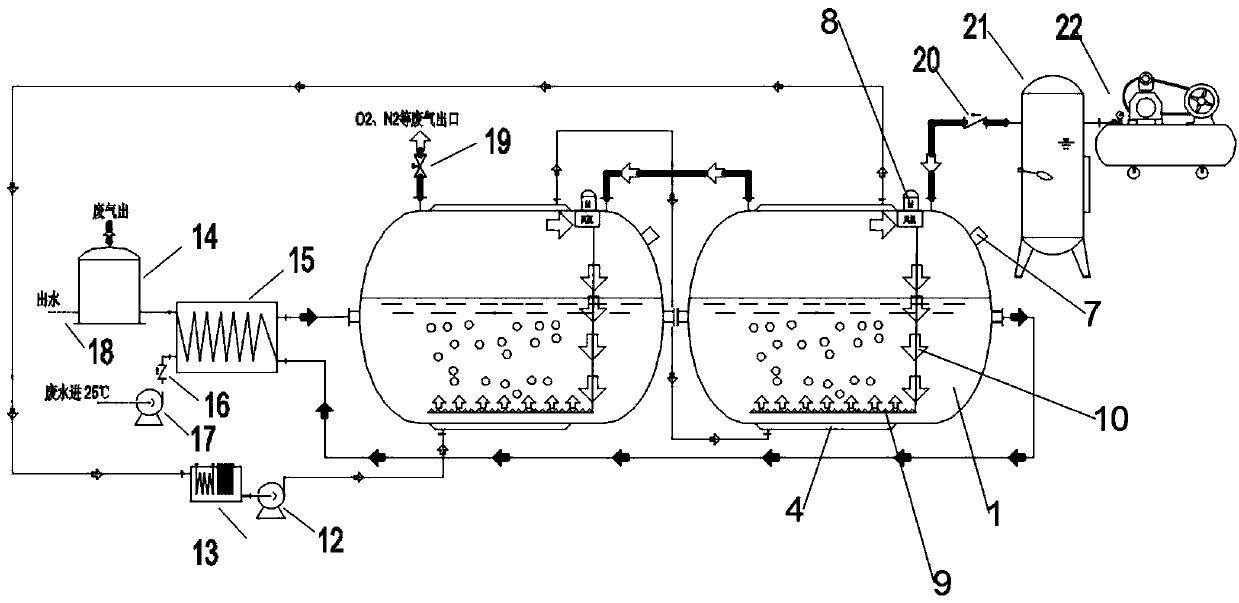

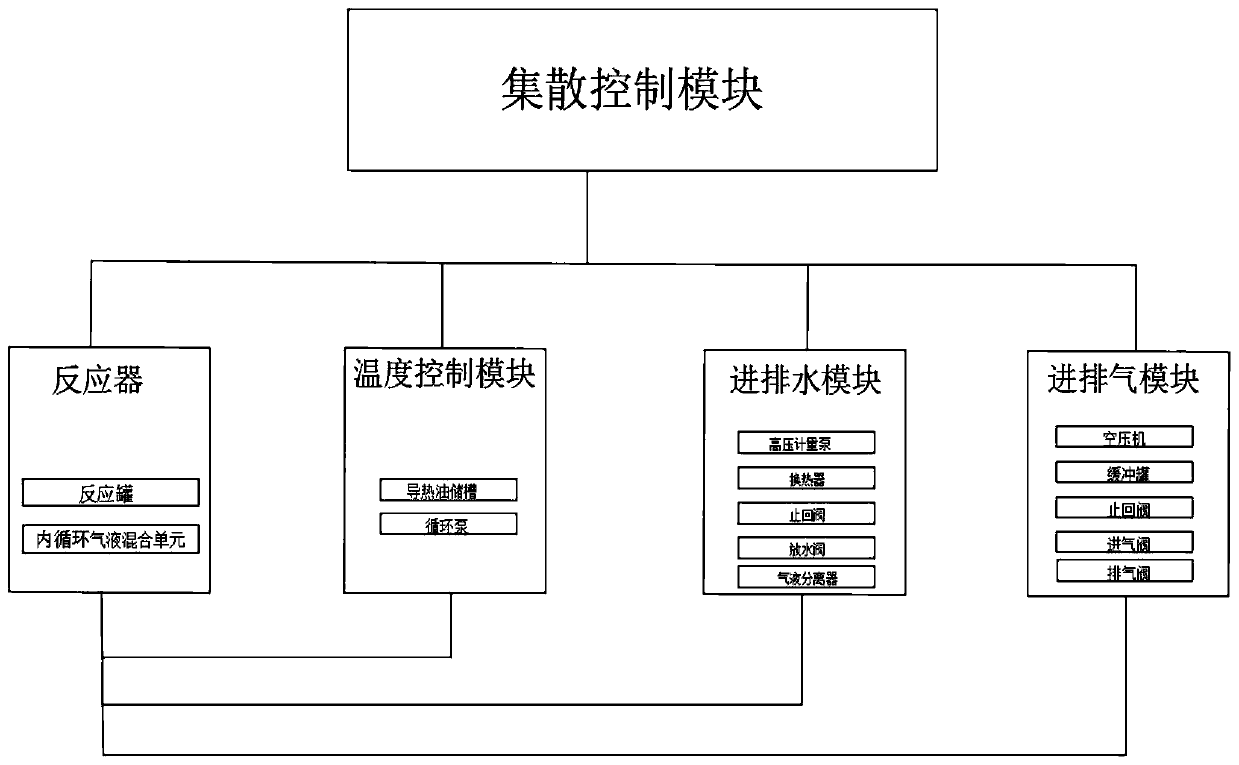

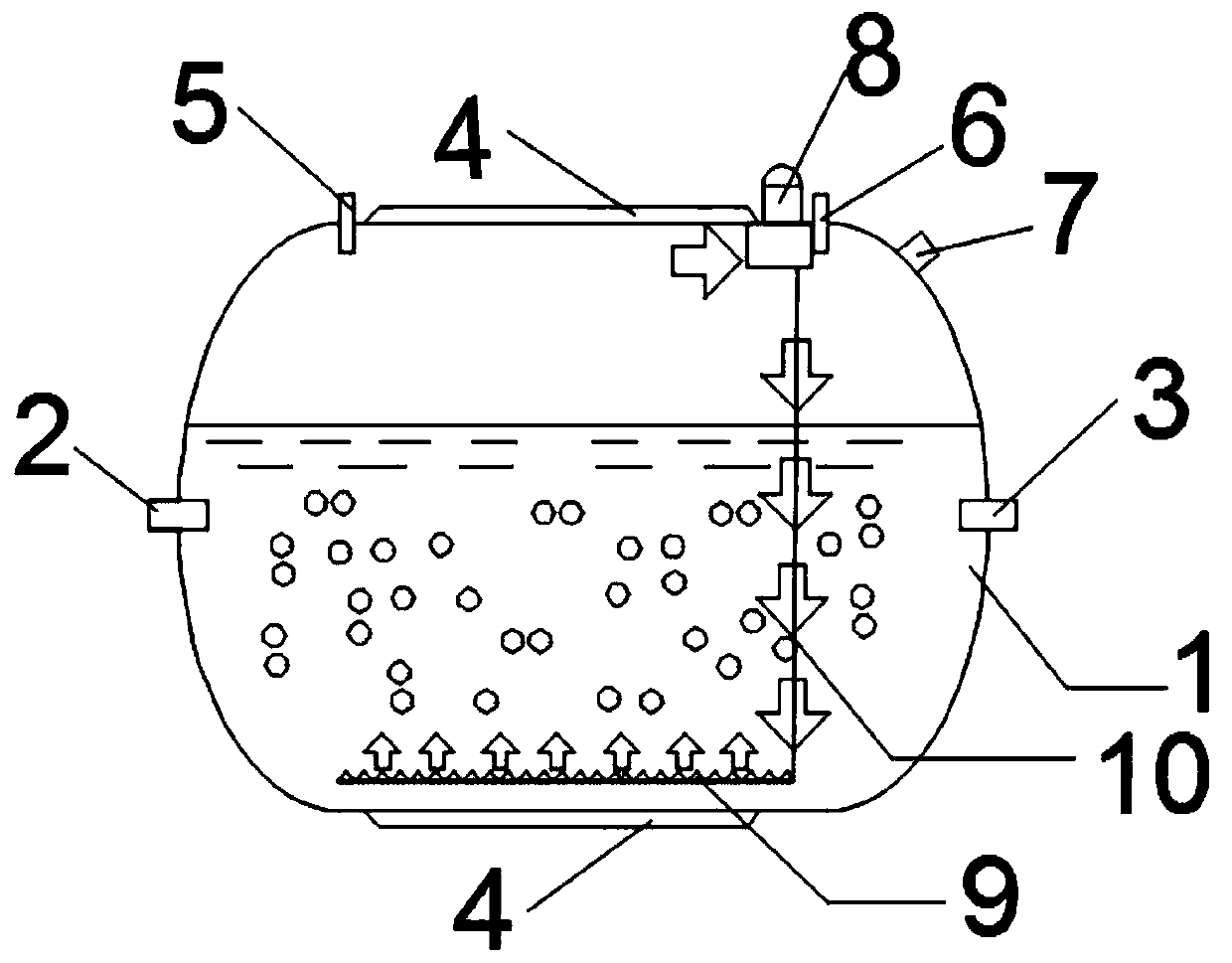

[0040] Embodiment 1: as figure 2 As shown, a wet oxidation reaction system, the oxidation reaction system includes one or a plurality of reactors in series, a temperature control module, an intake and exhaust module, an intake and drainage module and a collection and distribution control module, a temperature control module, an intake and exhaust module, The water inlet and drainage modules, the reactor and the distributed control module are electrically connected; the distributed control module is used to control the connection of all modules, and the gas-liquid mixing unit in the reactor can strengthen the gas-liquid mass transfer and stirring, independent of the intake and exhaust system, It is easier to control. The temperature control module can be heated and cooled by heat conduction oil, which is transported to the jacket of the reaction tank by a circulation pump to control the temperature of the reaction system. The intake and exhaust modules can control the intake fl...

Embodiment 2

[0058] Embodiment 2: The difference from Embodiment 1 is that the internal circulation gas-liquid mixing unit includes an air-dissolving pump 11 for inhaling the gas above the liquid level in the reaction tank and delivering it to the liquid in the reaction tank 1 for gas-liquid mixing, Aeration pipe 9 and aerator 10, dissolved air pump 11 can reach the effect similar to aeration fan 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com