Aeration device for treatment of environmental engineering sewage

A technology for sewage treatment and environmental engineering, applied in biological water/sewage treatment, water aeration, water/sludge/sewage treatment, etc. The effect of aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

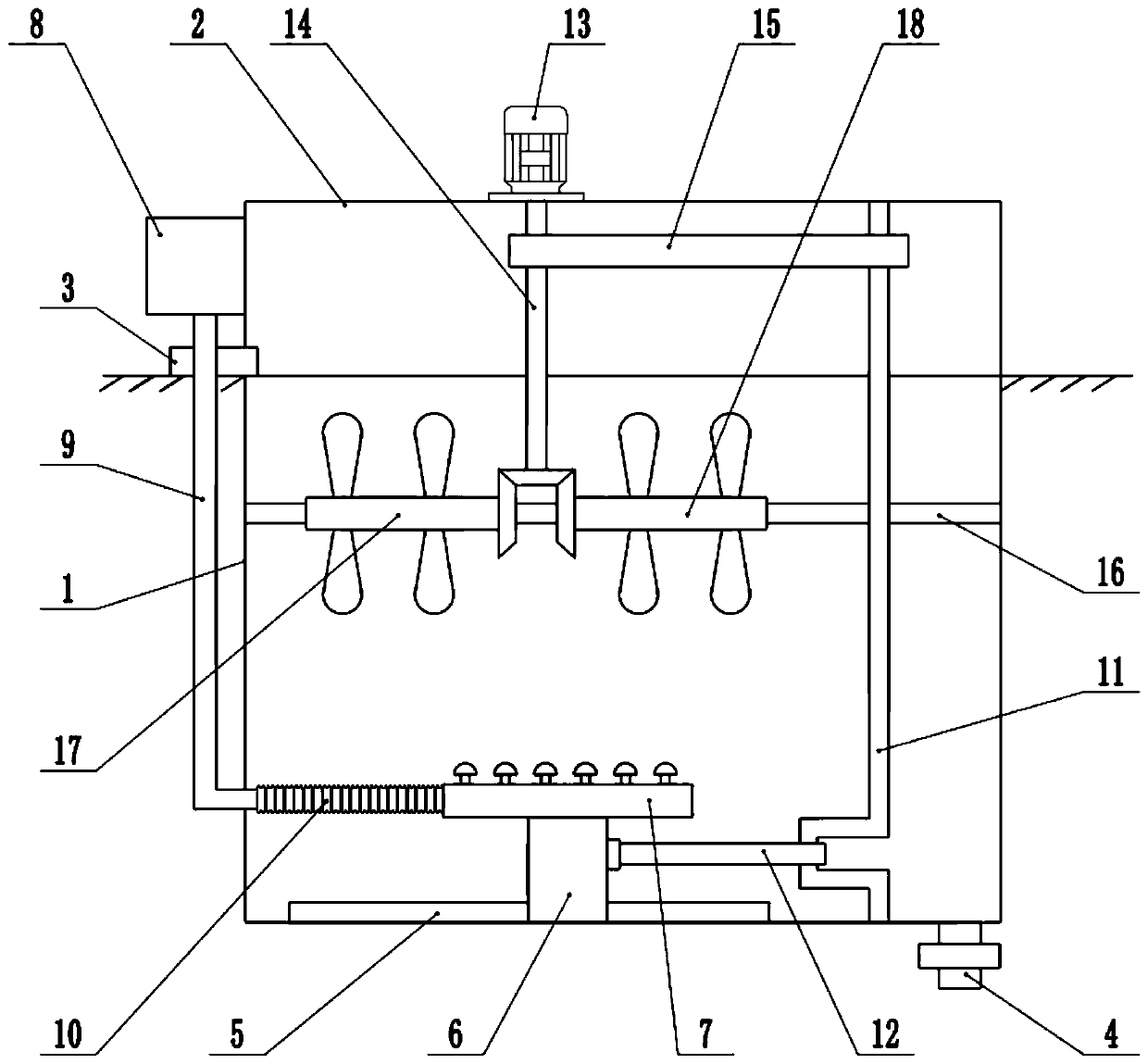

[0022] See Figure 1-3 In the embodiment of the present invention, an aeration device for environmental engineering sewage treatment includes a tank body 1, a water inlet pipe 3, a drain pipe 4, an aeration plate 7 and a blower 8. The top of the pool body 1 is fixedly connected with a fixing frame 2 A water inlet pipe 3 is installed above the side wall of the pool body 1, sewage is injected into the pool body 1 through the water inlet pipe 3, a drain pipe 4 is installed at the bottom of the pool body 1, and a valve is installed on the drain pipe 4, and the treated sewage passes through The drain pipe 4 is discharged. A slide rail 5 is installed at the bottom of the pool body 1, and a slide block 6 is slidably connected to the slide rail 5. The slide block 6 can slide left and right along the slide rail 5, and the upper surface of the slide block 6 is fixedly connected with aeration Disk 7, aeration disk 7 is hollow, aeration heads are distributed on the upper surface of the aer...

Embodiment 2

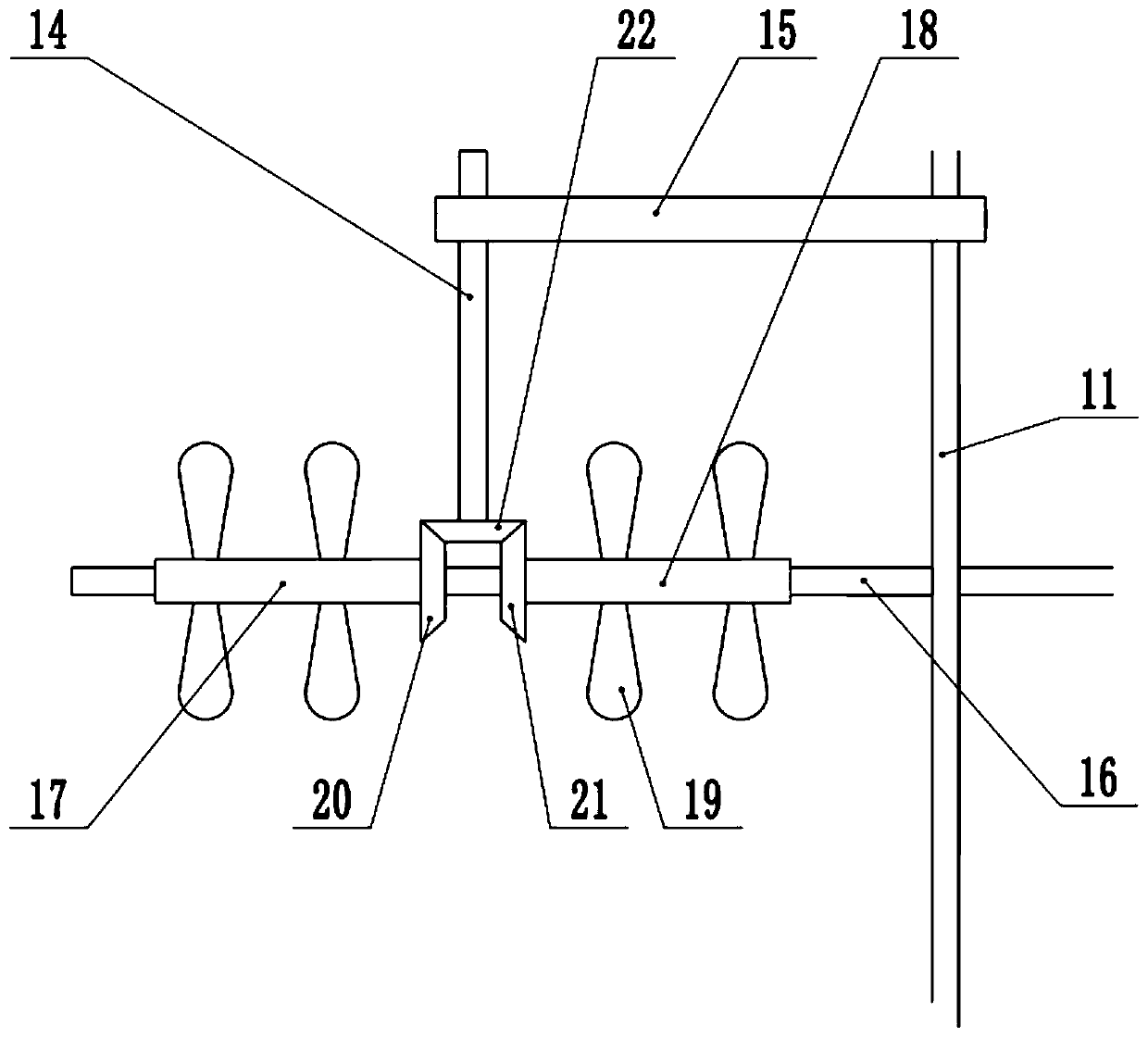

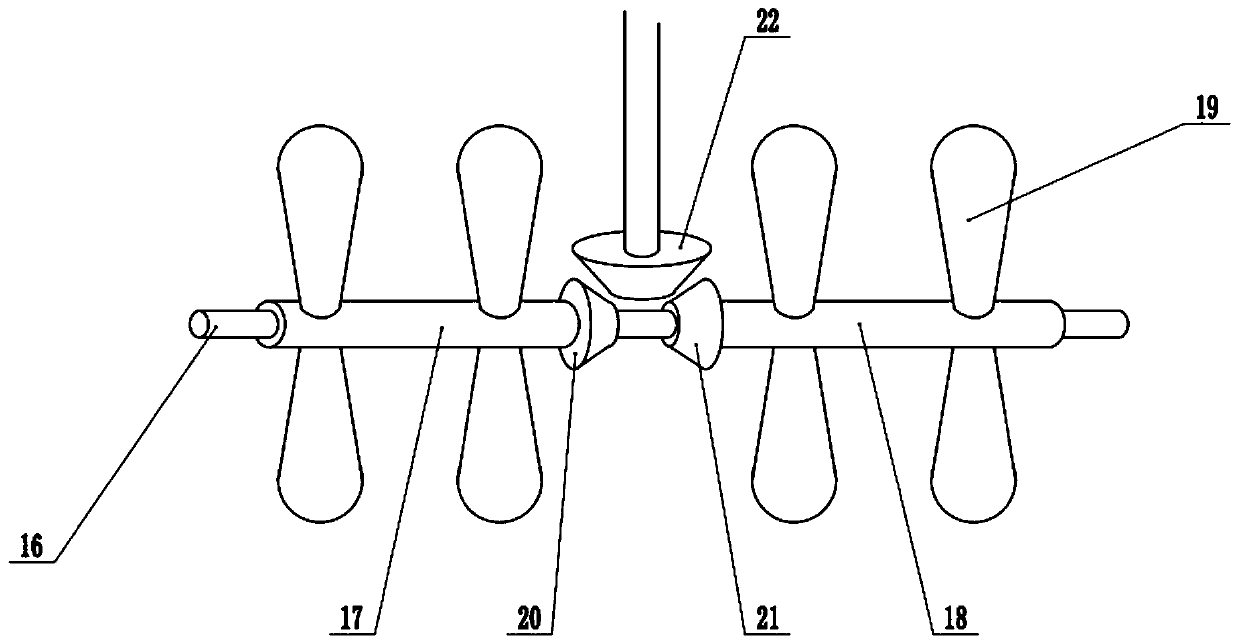

[0024] On the basis of embodiment 1, the right end of the left sleeve 17 is sleeved with a left bevel gear 20, the left end of the right sleeve 18 is sleeved with a right bevel gear 21, the lower end of the drive shaft 14 is sleeved with an upper bevel gear 22, and the left bevel gear The gear 20 and the right bevel gear 21 respectively mesh with the upper bevel gear 22. When the motor 13 is running, the drive shaft 14 is driven to rotate, which in turn drives the left sleeve 17 and the right sleeve 18 to rotate synchronously, and the left sleeve 17 and the right sleeve 18 The aeration blade 19 is used to agitate the sewage. Because the left sleeve 17 and the right sleeve 18 rotate in opposite directions, the uncertainty of sewage disturbance during the mixing process is increased, so that the sewage and bubbles are mixed more evenly and further improved Aeration efficiency.

Embodiment 1、 Embodiment 2

[0025] Combining Embodiment 1 and Embodiment 2, the working principle of the present invention is: sewage is injected into the tank body 1 through the water inlet pipe 3, so that the sewage floods the aeration blades 19, starts the blower 8, and uses the blower 8 to transport air to the aeration tray 7. , And then discharged into the sewage through the aeration head on the aeration plate 7 to aerate the bottom sewage. At the same time, the motor 13 is started. When the motor 13 is running, the drive shaft 14 is driven to rotate, and the crankshaft 11 is driven to rotate synchronously through the transmission belt 15. When 11 rotates, the slider 6 is driven to move left and right along the slide rail 5 through the connecting rod 12, thereby driving the aeration plate 7 to move left and right, so that bubbles are discharged into the sewage more evenly, and the aeration efficiency is improved. Moreover, when the motor 13 is running , Drives the drive shaft 14 to rotate, and then dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com