Pre-combustion chamber, engine and vehicle

A technology of pre-combustion chamber and pre-combustion chamber, which is applied in the field of pre-combustion chamber, engine and vehicle, which can solve the problems affecting combustion stability, thermal efficiency, thermal efficiency and emission, combustion stability, etc., so as to reduce residual exhaust gas and improve emission , Improve the effect of combustion heat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

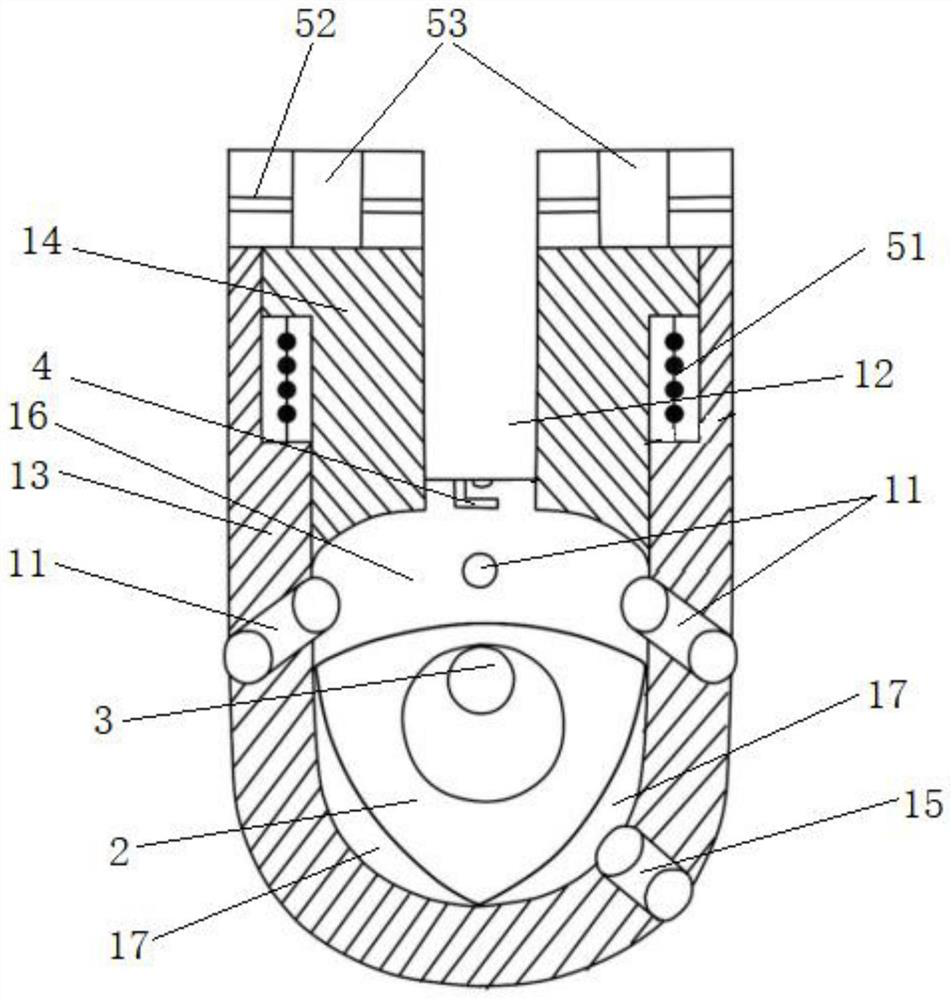

[0022] like figure 1 As shown in a pre-chamber provided by the invention, comprises a cavity 1, a gear 3, the triangle rotor 2 and the ignition device 4; precombustion chamber 1 has a cavity, the gear 3 rotatably mounted in the cavity wall of the cavity 1, and pre-combustion chamber is located, the precombustion chamber, the triangle rotor 2 is provided in a motion cam rotor having an inner ring 2, the triangle rotor 2 via the ring gear meshing with the gear 3, precombustion chamber inner profile of the rotor 2 and the triangular track match, the gear 3 and the triangle rotor 2 together form a planetary gear set and the triangle rotor 2 rotates together precombustion chamber wall, the exhaust gas is purged inside the precombustion pre-chamber, the gas inside was sufficiently stirred field precombustion chamber to ensure the uniformity of scavenging. Cavity wall of the cavity 1 is provided with a mounting hole in communication with the precombustion chamber 12, the ignition device ...

Embodiment 2

[0035] Based on the same inventive concept, this embodiment provides an engine comprising a primary combustion chamber and a pre-combustion chamber provided by Example 1, and the main combustion chamber communicates with the pre-combustion chamber by a nozzle 11, ie the pre-combustion chamber of the engine. The body 1 employs the structure provided in Example 1 and sets the planetary gear set composed of triangular rotor 2 and gear 3 in the cavity 1, the present invention can be used for the type and type of the engine, which can be any of the prior art. The engine, the other unreal detailed structures of the engine can refer to the disclosure of the prior art, which is not described herein.

Embodiment 3

[0037] Based on the same inventive concept, this embodiment provides a vehicle including an engine provided in Example 2. Due to the pre-combustion chamber structure in Example 1, the vehicle naturally has the corresponding all technical effects. The present invention does not specifically limit the type and type of the vehicle, and may be any of the prior art, such as a general passenger car, passenger car, truck, etc., the other unknown structures of the vehicle can be referred to the prior art. The relevant disclosure, which is not described here.

[0038] By the above embodiment, the present invention has the following beneficial effects or advantages:

[0039] 1) The triangular rotor and gear constitute the planetary gear set, and the triangular rotor always carries the cavity when the triangle rotor, by providing uniformly sweeping triangle rotor in the pre-combustion chamber, the pre-combustion exhaust gas is purged inside the pre-combustion chamber. , Fully agitated the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com