Gas well production liquid storage device with multi-stage defoaming function and use method

A technology of storage device and defoaming device, which is applied in the valve device of wellbore/well, earthwork drilling, flushing wellbore, etc. Utilization, reduce the time used, ensure the effect of continuous normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

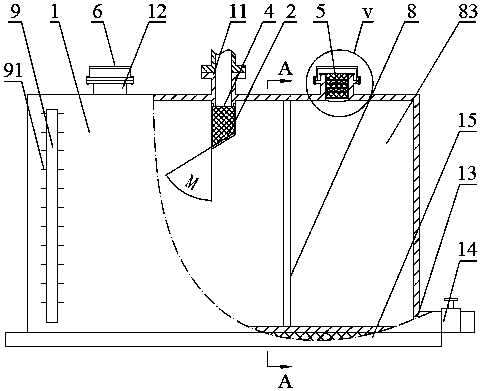

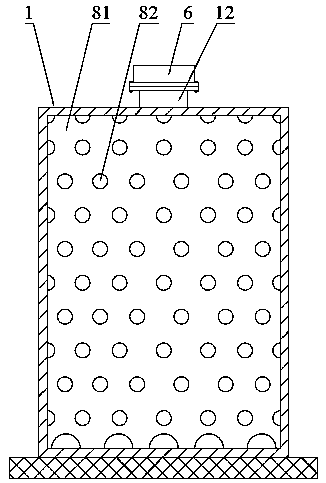

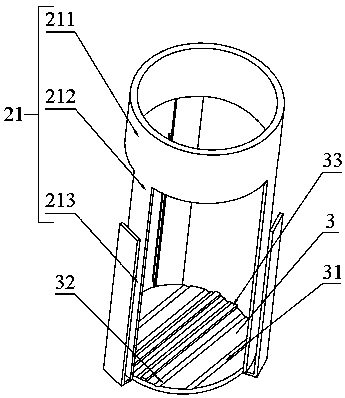

[0040] Such as Figure 1-3 As shown, the gas well production liquid storage device with multi-stage defoaming function includes a liquid storage tank 1, and the liquid storage tank 1 is provided with a liquid inlet 11 and a liquid discharge port 13, and the liquid inlet 11 is connected to the liquid through a pipeline. The oil pipes and / or casings of the gas tree are connected, the liquid discharge port 13 is provided with a control valve 14 that can be opened and / or closed, the liquid inlet port 11 is arranged on the top of the liquid storage tank 1, and the liquid discharge port 14 is arranged on the bottom edge of one side of the liquid storage tank 1, the bottom of the liquid storage tank 1 is also provided with a base 15, the liquid storage tank 1 is detachably connected with the base 15, and the liquid storage tank 1 is provided with At least one defoaming device, the defoaming device includes a liquid inlet defoaming mechanism 2, the liquid inlet defoaming mechanism 2 i...

Embodiment 2

[0045] Such as figure 1 and image 3 As shown, the structure of the gas well liquid storage device with multi-stage defoaming function in this embodiment is the same as that of Embodiment 1, the difference is that the deflector 3 is provided with a buffer mechanism for separating foam For the gas and liquid in the buffer mechanism, the buffer mechanism includes a guide groove 31 and / or a guide rib 32 and / or an adsorption mechanism 33 to form a second-stage defoaming treatment structure.

[0046] The gas well production liquid storage device with multi-stage defoaming function in this embodiment, by setting the flow guide groove 31 on the deflector 3, is beneficial to make the gas well production fluid entering from the liquid inlet hit the deflector 3 Concentrate the flow along the diversion grooves 31 to increase the liquid flow in each diversion groove 31, thereby reducing the foam in the gas well production fluid, so that the defoaming effect is better.

[0047] More pref...

Embodiment 3

[0050] Such as Figure 1-4 As shown, the gas well production liquid storage device with multi-stage defoaming function of this embodiment has the same structure as that of Embodiment 2, the difference is that the defoaming device also includes a filter defoaming mechanism 4, and the filter defoaming mechanism 4 Including at least one layer of defoaming net 41, the bracket 21 is provided with a clamping groove 213 for clamping the defoaming net 41, and the defoaming net 41 is detachably arranged in the clamping groove 213. A liquid-inlet defoaming space 42 is formed between the flow plate 3 and the liquid inlet 11, forming a third-stage defoaming treatment structure.

[0051] In the gas well production liquid storage device with multi-stage defoaming function in this embodiment, it is preferable that the connecting strip 212 on the bracket 21 is folded outward to form a clamping groove 213 for clamping the defoaming net 41, and the defoaming net 41 is made of steel wire filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com