Integrated simulation method coupling the hydraulic fracturing, flowback and production processes of shale gas reservoir

A production process and hydraulic fracturing technology, which is applied in the fields of mining fluid, earthwork drilling, design optimization/simulation, etc., and can solve problems that do not take into account the two-phase seepage relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

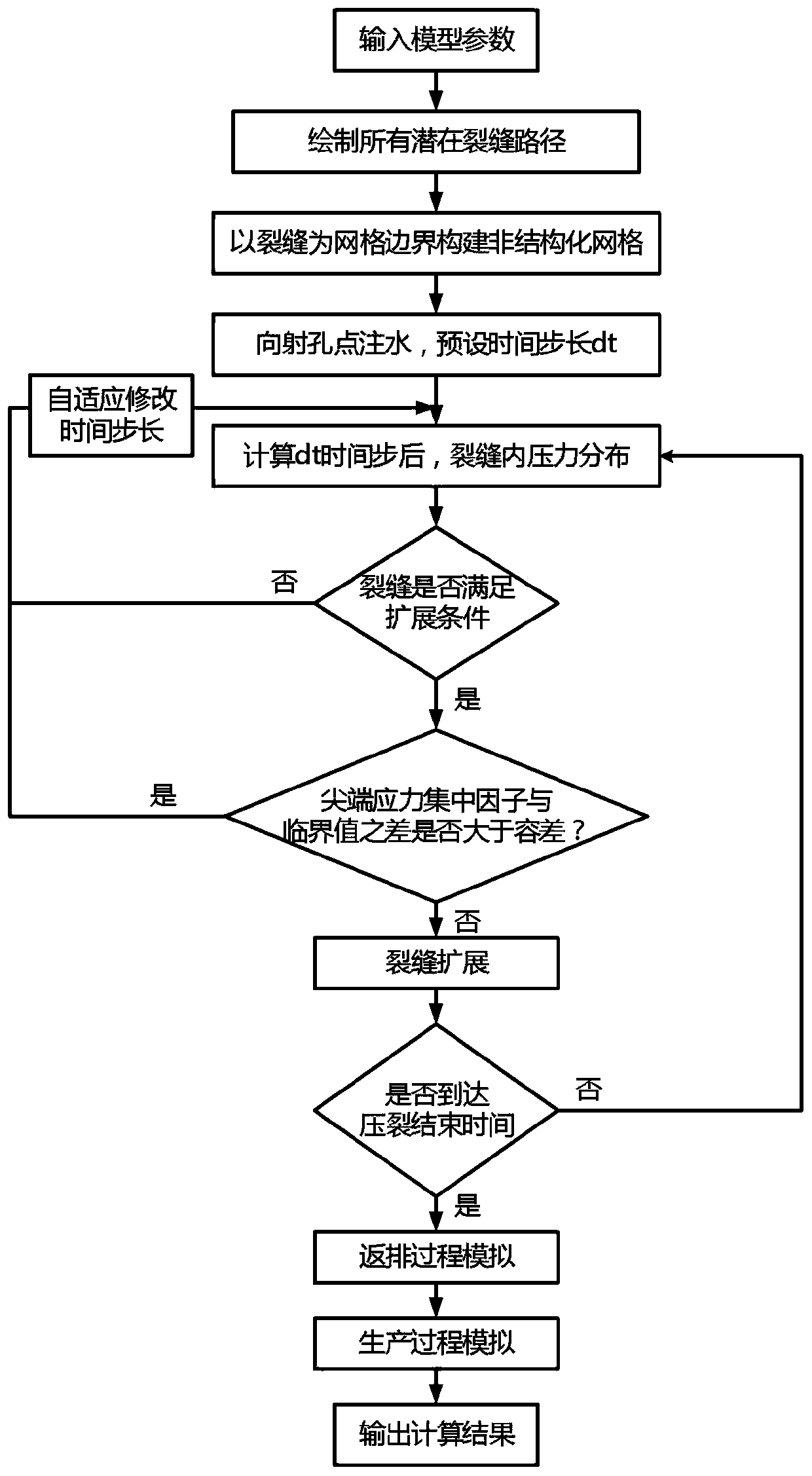

[0062] An integrated simulation method for hydraulic fracturing flowback production process coupled with shale gas reservoirs, such as figure 1 As shown, it is a flow chart of the integrated simulation method for hydraulic fracturing flowback production process coupled with shale gas reservoirs of the present invention, including the following steps:

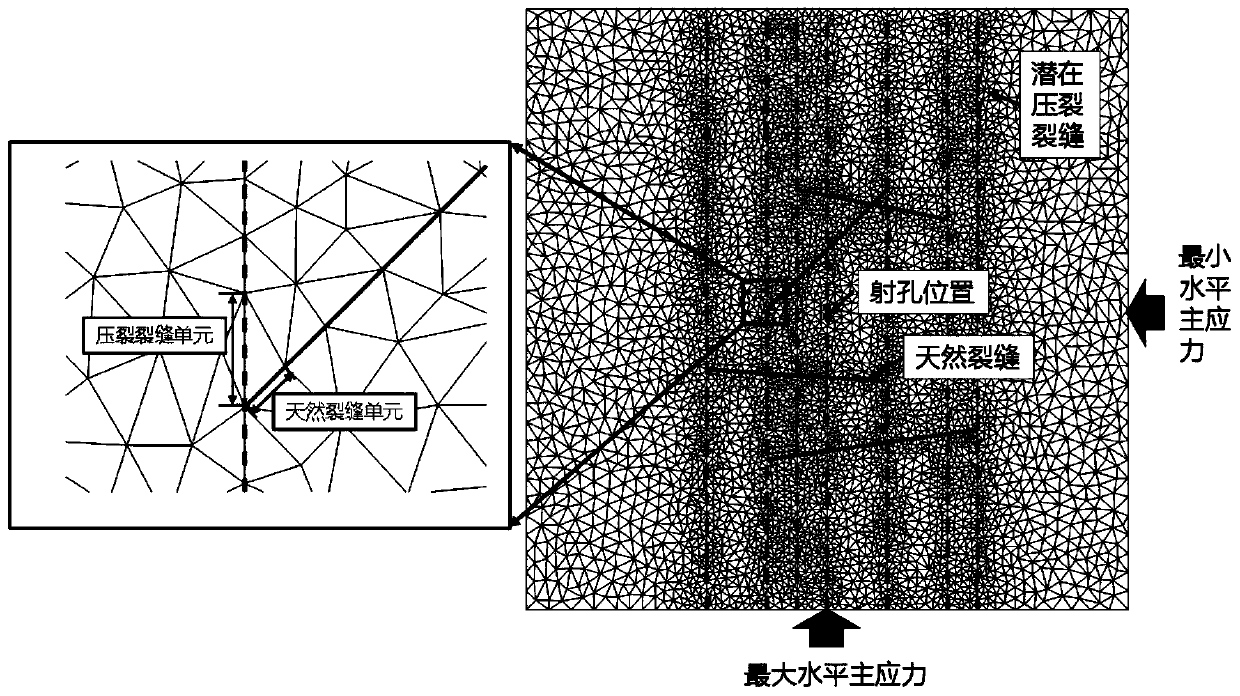

[0063] (S1) Based on the distribution of natural fractures in the formation, the magnitude and direction of the in-situ stress, all fractures are set to be perpendicular to the direction of the minimum horizontal principal stress, and the fractures can pass through natural fractures or not. The possible expansion paths of all fractures are set, and they are divided into two types: fracturing fractures and natural fractures, such as figure 2 As shown, it is the characteristic map of the fracture path and the discrete fracture grid described in the present invention;

[0064] (S2) see figure 2 , taking all potential fractures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com