Thermostatic valve, control method thereof and water heater with the same

A control method and thermostatic valve technology, applied in fluid heaters, lighting and heating equipment, valve operation/release devices, etc., can solve the problems of inability to achieve timely change adjustment, long adjustment time, and low degree of intelligence, and achieve Improved user experience, short adjustment time, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

[0024] In the description of the present invention, unless otherwise clearly defined, terms such as setting and connecting should be understood in a broad sense, and those skilled in the art can reasonably determine the specific meanings of the above terms in the present invention in combination with the specific content of the technical solution.

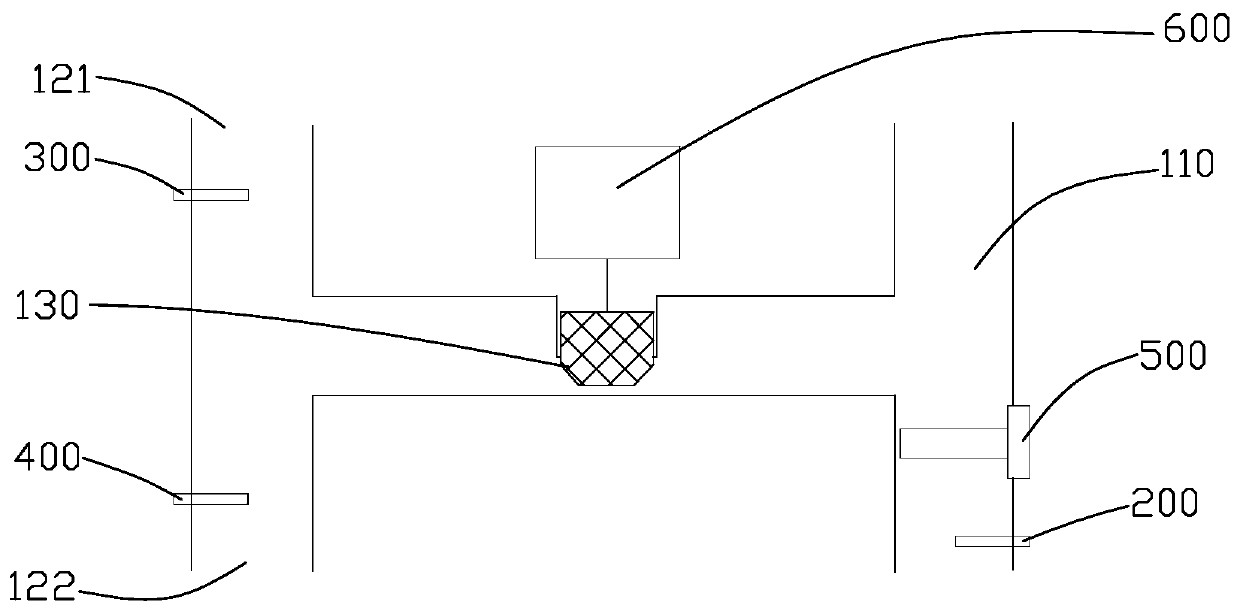

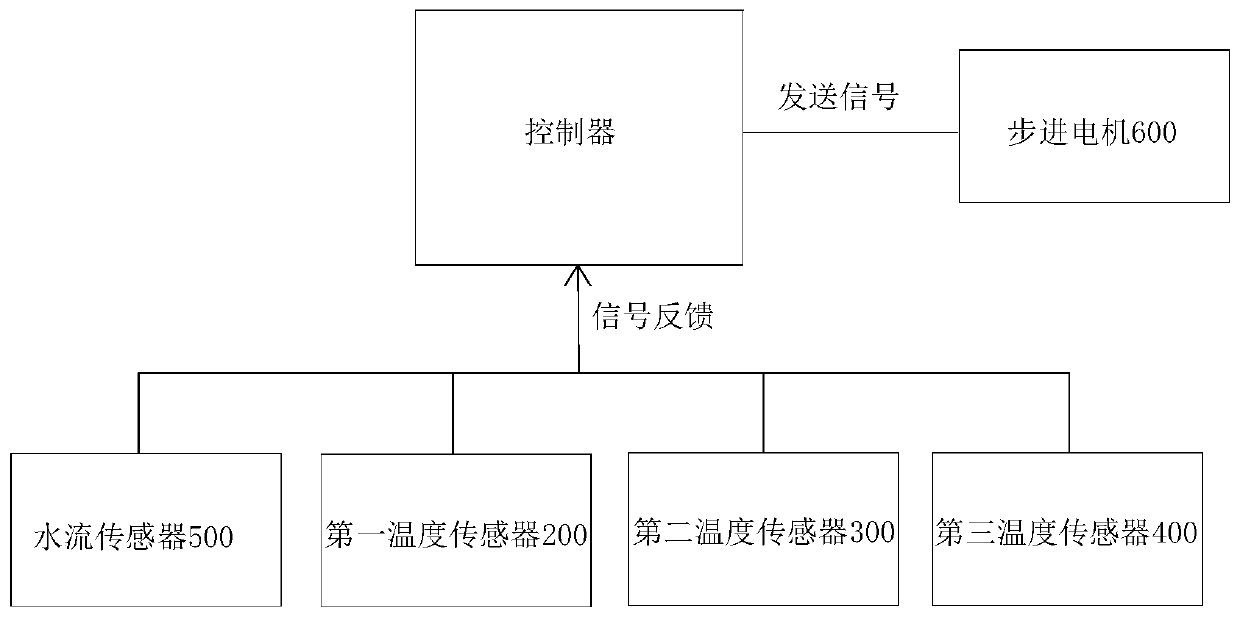

[0025] refer to Figure 1 ~ Figure 2 , taking the thermostatic valve used in the water heater as an example, the thermostatic valve of the present invention makes the following embodiments:

[0026] Including the valve body 100, the valve body 100 is provided with an inner cavity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com