Rock sample axial extensometer

A rock sample and extensometer technology, applied in the field of rock mechanics test, can solve the problems of long time for sample installation, inability to install axial extensometer, poor matching applicability of extensometer, etc., to achieve perfect accuracy and save scientific research. The effect of shortening time and installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

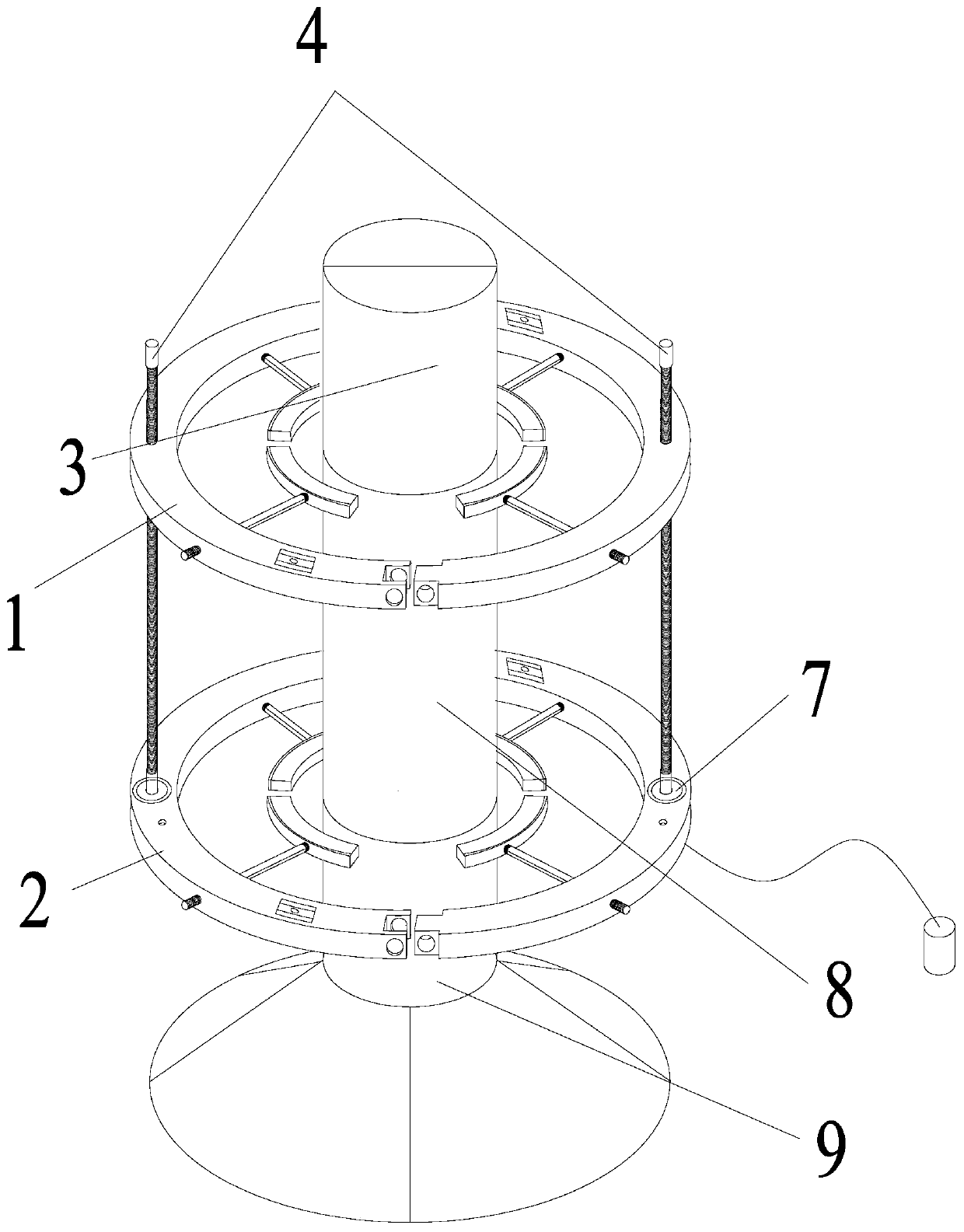

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

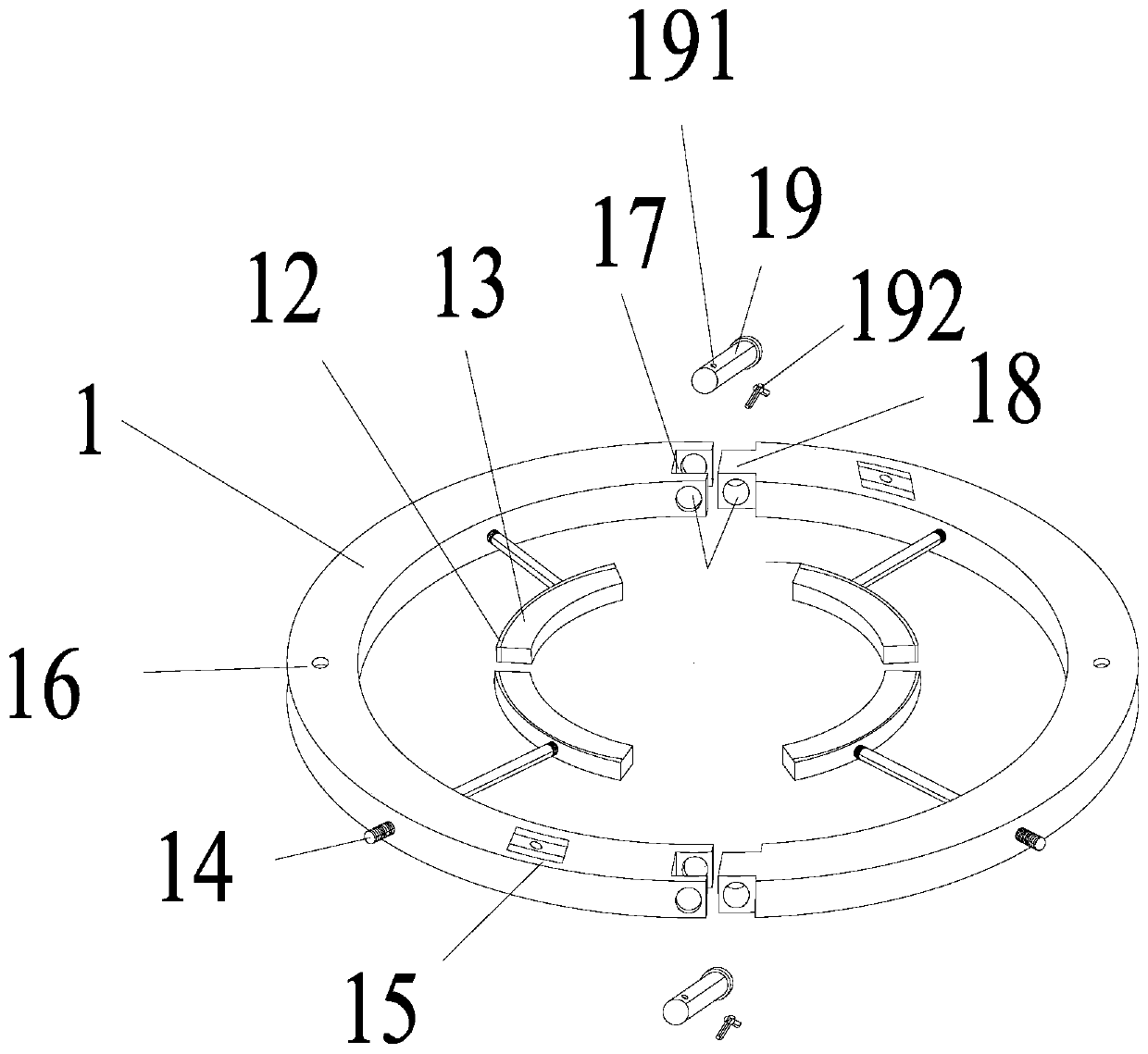

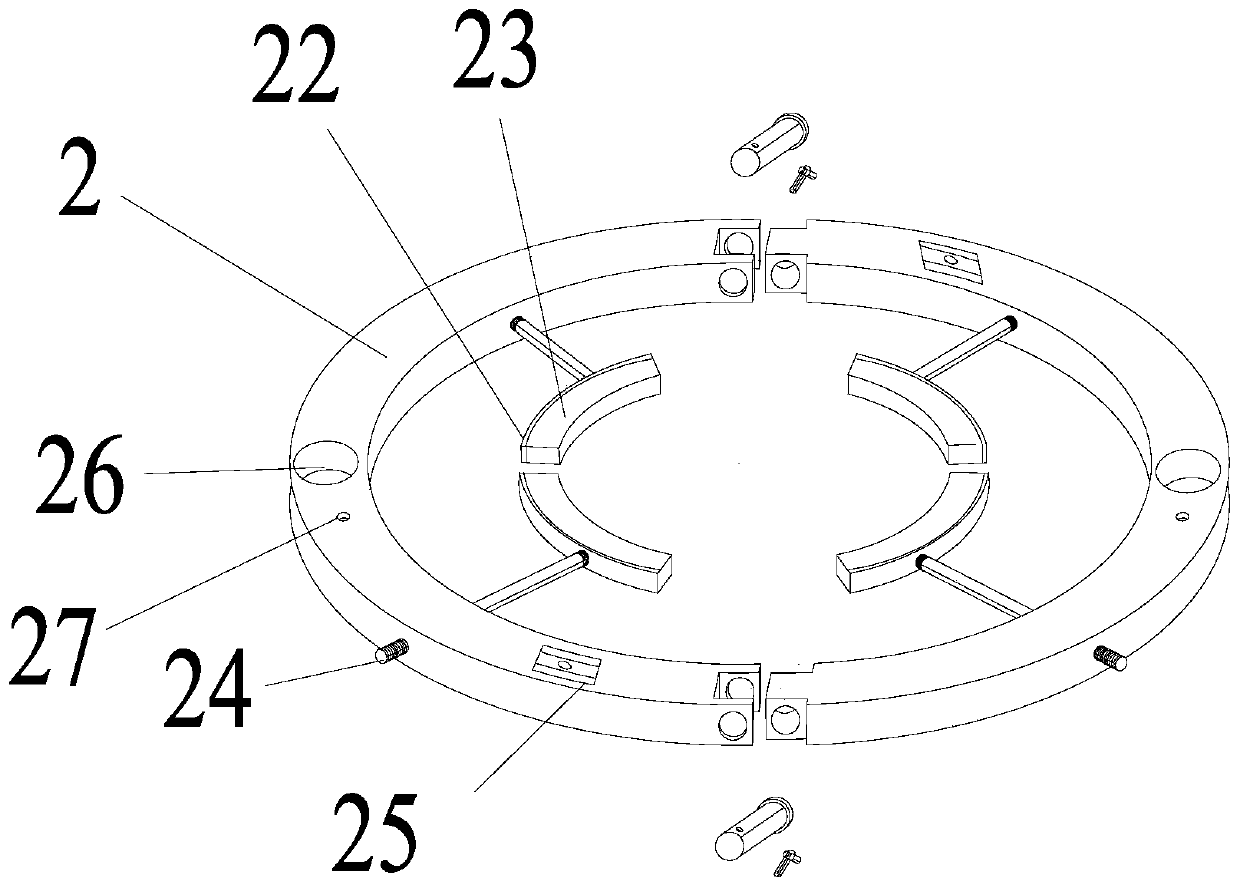

[0024] A rock sample axial extensometer, reference Figures 1 to 5 , comprising an upper ring and a lower ring; the upper ring is formed by splicing two first half rings 1, and the lower ring is formed by splicing two second half rings 2;

[0025] The first semi-circular ring 1 is provided with a first extension rod placement hole 16 and a first columnar horizontal air bubble 15; the side wall of the first semi-circular ring 1 is also provided with two first adjustment holes; The two ends of the first half ring 1 are specifically the first mortise and tenon structural elements; the upper ring also includes a first fixing device; the first fixing device includes four identical and center-symmetrically arranged first arc-shaped stainless steel 12. The outer wall of the first arc-shaped stainless steel 12 is also provided with a first adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com