Crude salt quality detection system

A technology for quality inspection and coarse salt, applied in the field of salt production, can solve the problem that the test solution cannot be re-made into refined salt, affecting the accuracy, etc., and achieves the effects of improving convenience, reducing inaccurate detection and fast solution speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

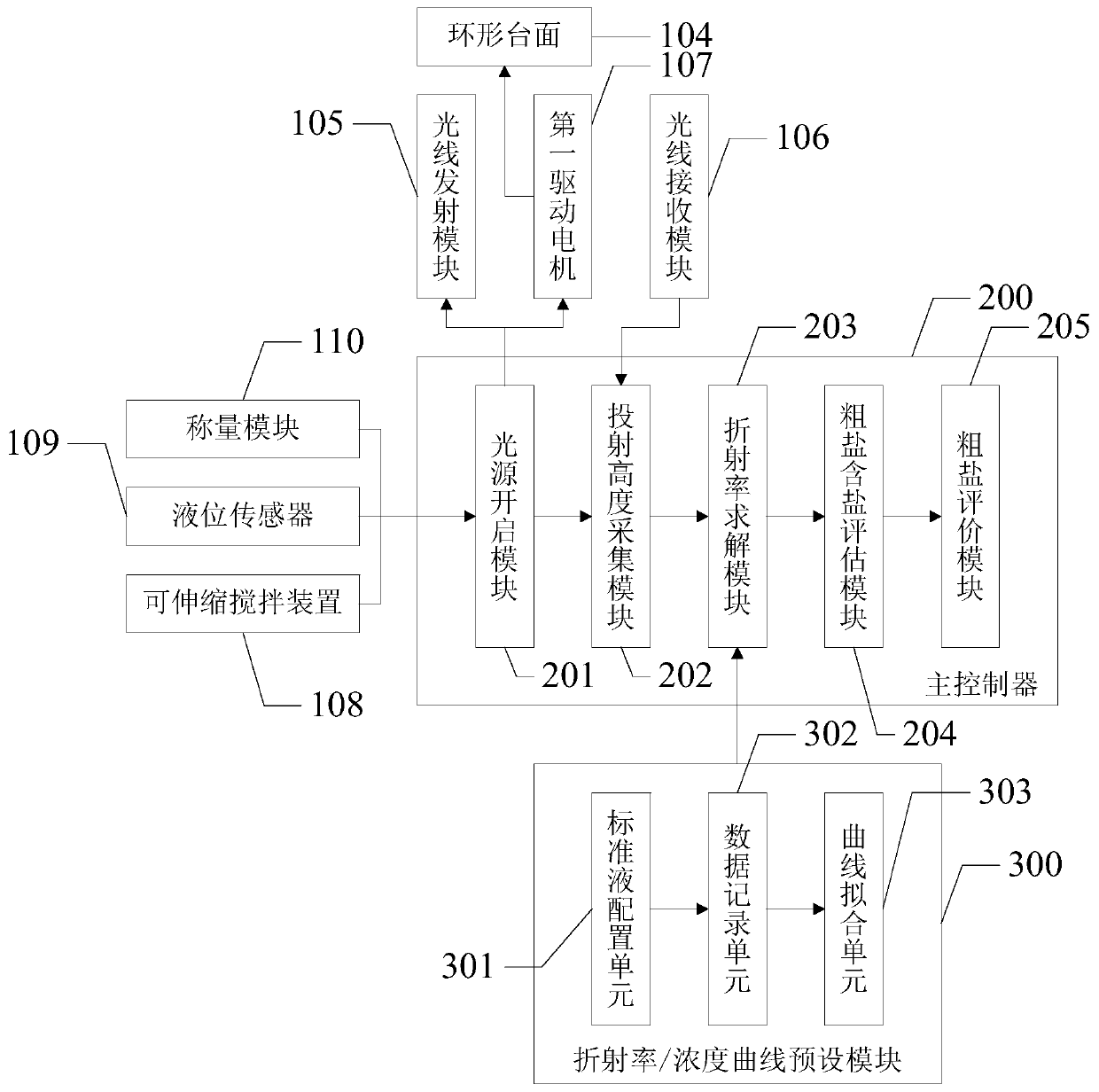

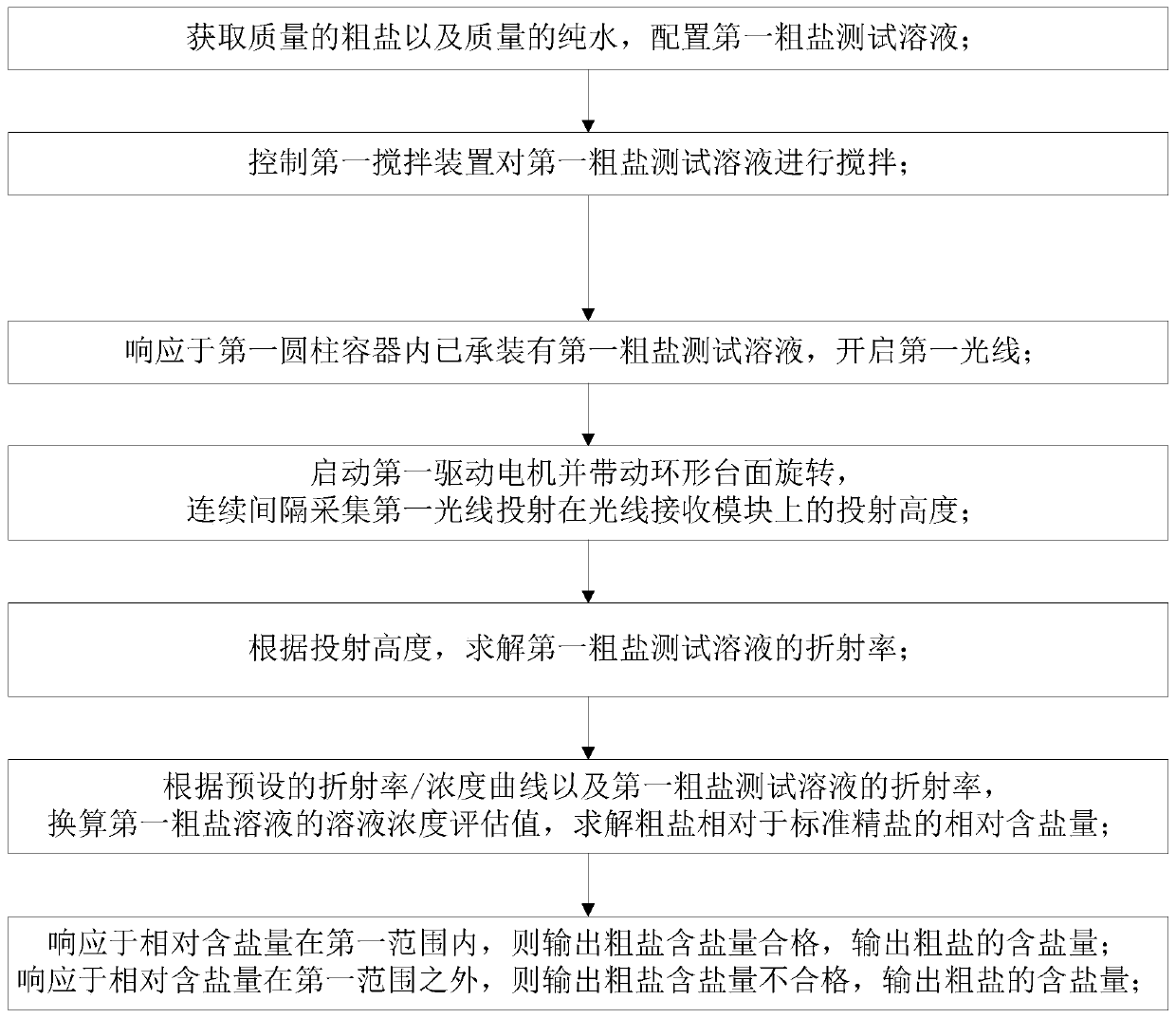

[0045] Such as Figure 1-4 As shown, in the first embodiment of the present invention, a kind of rough salt salt content testing method is provided, and described method comprises:

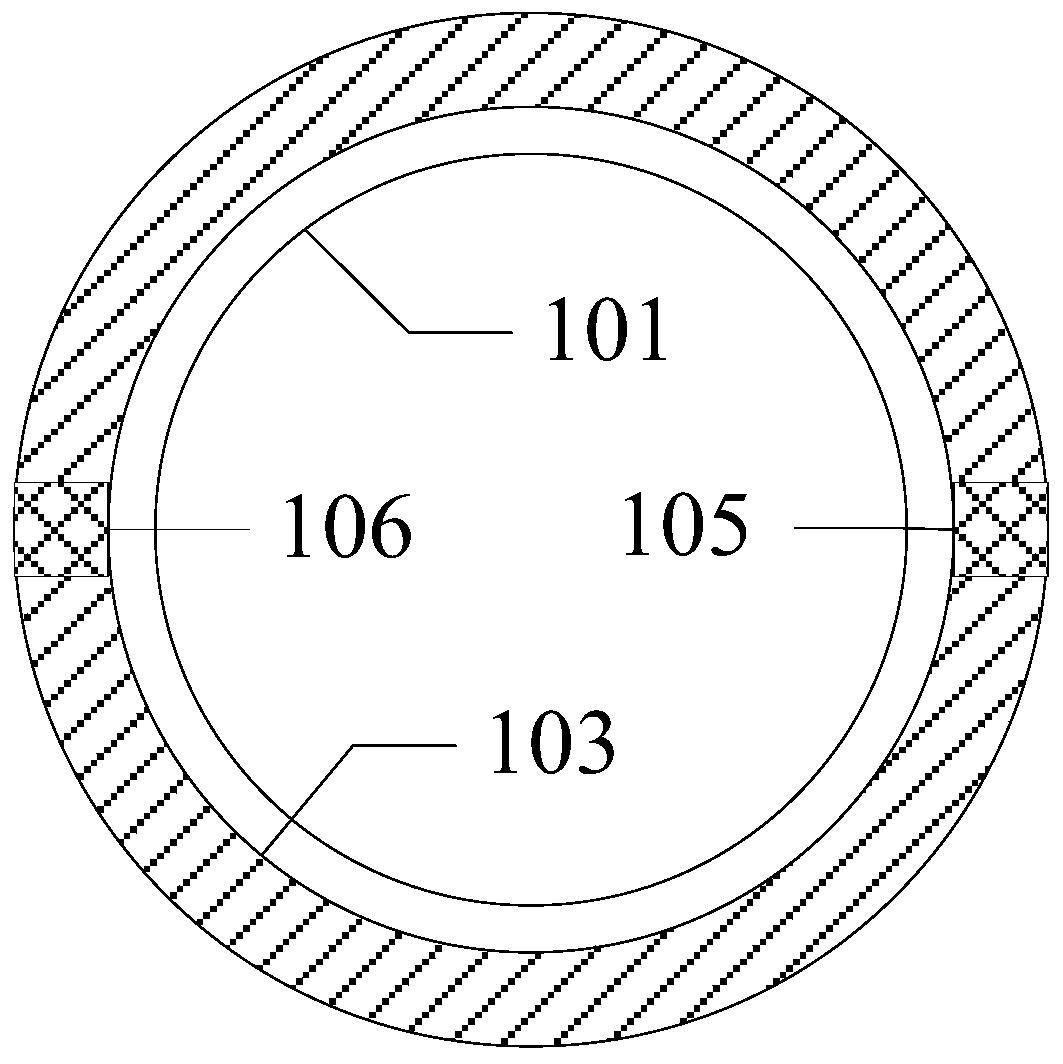

[0046] In response to the first coarse salt test solution being contained in the first cylindrical container, the first light is turned on; wherein, the first cylindrical container is used to accommodate the first coarse salt test solution; the bottom of the first cylindrical container is provided with The first reflector; a ring-shaped test mounting track is arranged on the periphery of the first cylindrical container, and the ring-shaped test mounting track is coaxial with the first cylindrical container; a ring-shaped table is mounted on the ring-shaped test mounting track, and the A light-emitting module and a light-receiving module are mounted on the ring-shaped table; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com