Storage tank fire extinguishing device and fire extinguishing method

A fire extinguishing device and storage tank technology, applied in the field of oil tank fire extinguishing, can solve the problems of hot oil tank boiling over, inability to effectively control and extinguish fire, etc., and achieve the effect of solving the difficulty of fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The gas source unit adopts compressed nitrogen, which comes from the site’s own nitrogen pipeline. The solid powder fire extinguishing agent uses hollow glass beads (particle size 1.0-2.0mm), and the foam fire extinguishing agent chooses aqueous film-forming foam fire extinguishing agent (AFFF) .

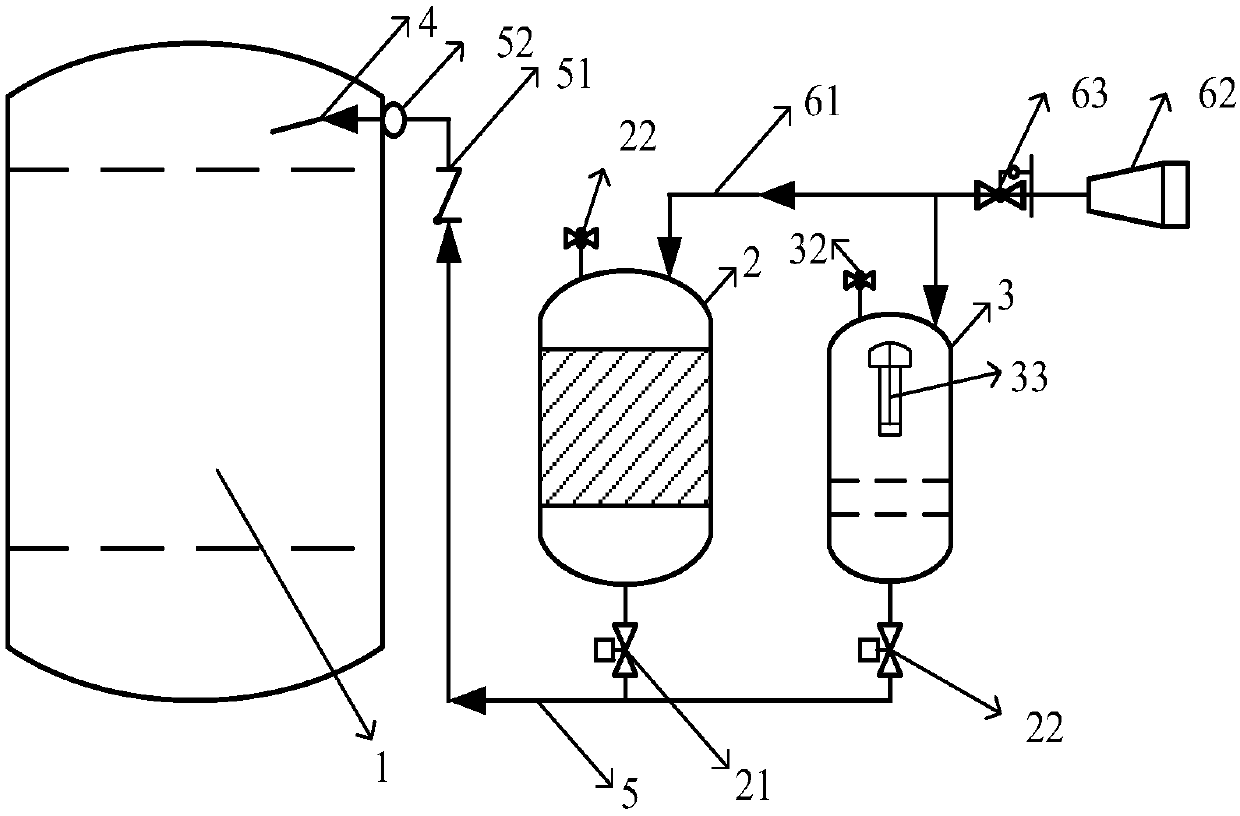

[0085] When a fire occurs in the high-temperature hot oil storage tank, start the preset program of the control unit, and the high-pressure nitrogen in the gas supply pipeline 61 is decompressed to 1.2 MPa by the pressure reducing valve 63, and then enters the solid powder fire extinguishing agent unit 2 and the foam fire extinguishing agent at the same time Unit 3. The compressed nitrogen first pushes the hollow glass microbeads from the solid powder fire extinguishing agent unit 2 to the burst disc 52 through the one-way valve 51. The burst disc is opened due to low pressure, and the hollow glass microbeads are sprayed out from the injection port 4, thereby damaging the oil...

Embodiment 2

[0092] The same fire extinguishing conditions as in Example 1 are adopted, the difference is that the high temperature residual oil storage tank with a diameter of 3.6m and no nitrogen seal is used for fire extinguishing, the gas source unit uses liquid nitrogen, and the liquid nitrogen comes from the on-site liquid nitrogen tank, and the solid powder is The fire extinguishing agent is expanded perlite (particle size: 0.5-1.0mm), and the foam fire extinguishing agent is aqueous film-forming foam fire extinguishing agent (AFFF). The fire extinguishing effect is shown in Table 2.

Embodiment 3

[0099] The same fire extinguishing conditions as in Example 1 are adopted, the difference is that the high temperature residual oil storage tank with a diameter of 3.6m and no nitrogen seal is used for fire extinguishing, the gas source unit uses liquid nitrogen, and the liquid nitrogen comes from the on-site liquid nitrogen tank, and the solid powder is Expanded vermiculite (particle size: 1.0-1.5 mm) was selected as fire extinguishing agent, and solvent-resistant water film-forming foam fire extinguishing agent (AFFF / AR) was selected as foam fire extinguishing agent. See Table 3 for the fire extinguishing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com