An ultrasonic cleaning device

A washing device and ultrasonic technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of liquid overflow, affecting the washing effect, and low liquid level, so as to facilitate disassembly and installation, Ensure safe operation and ensure the effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

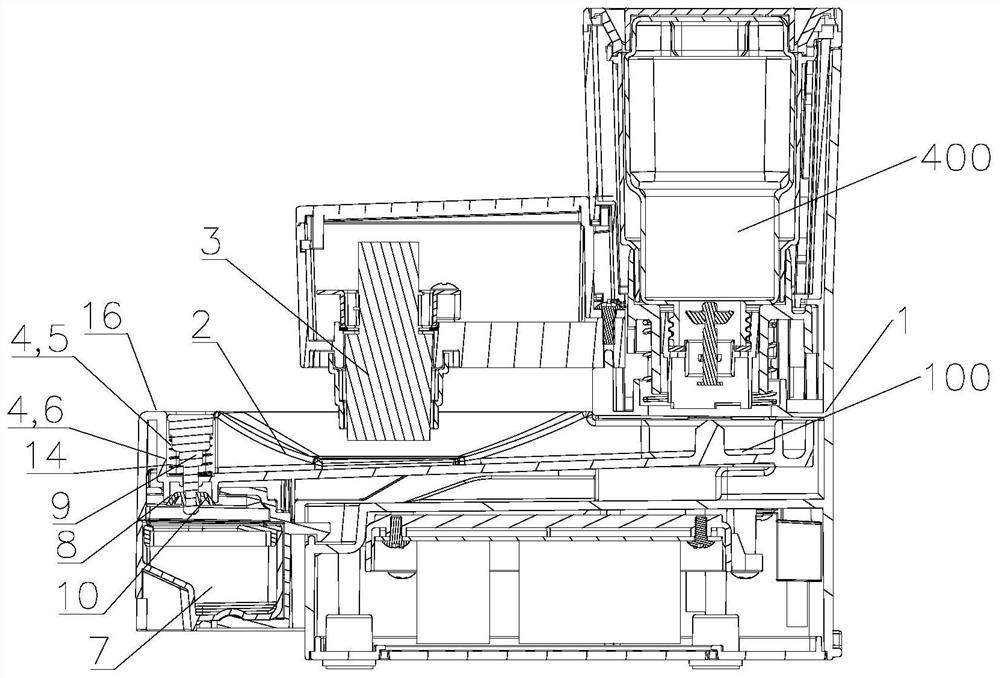

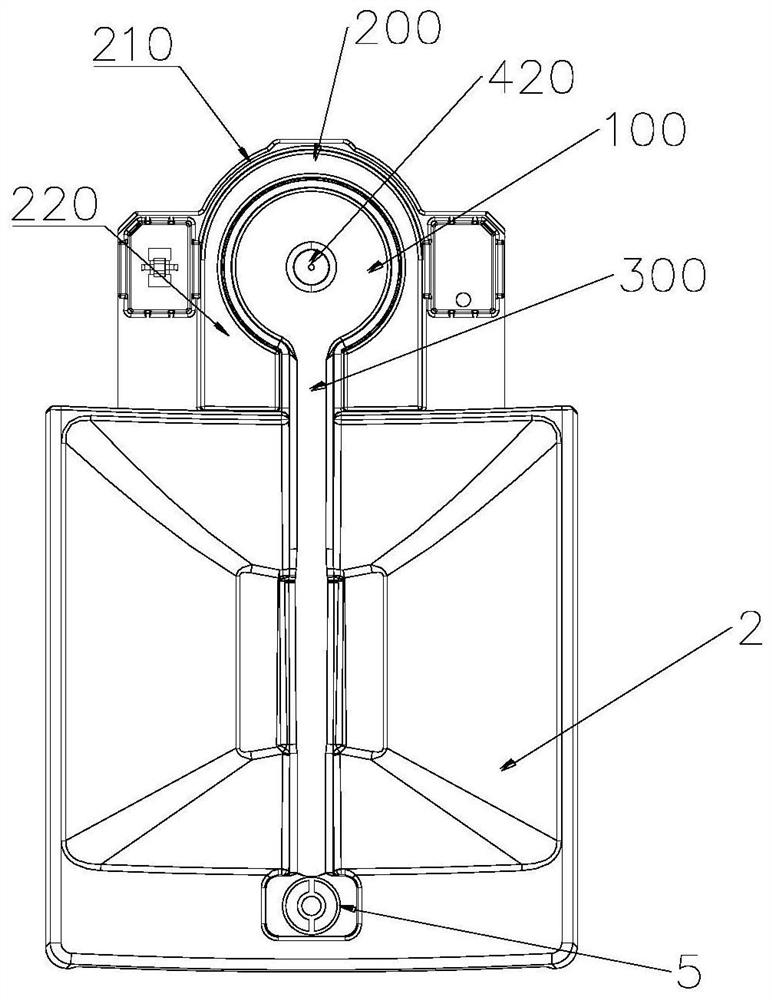

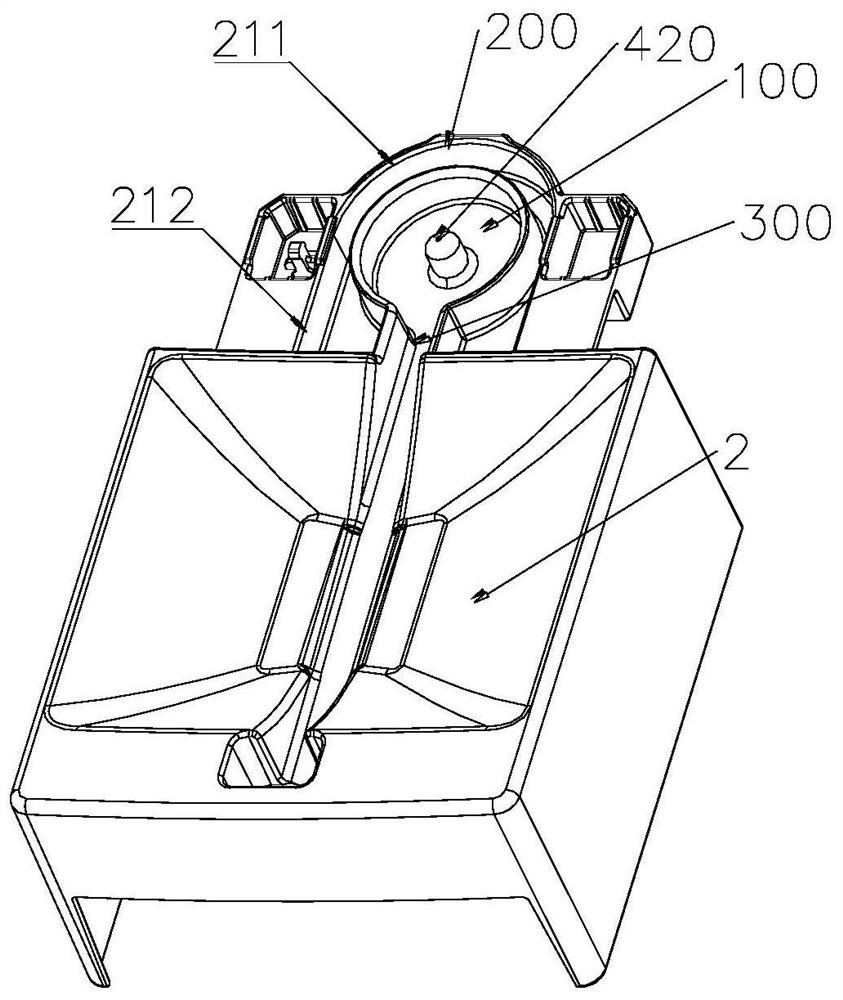

[0046] Such as Figure 1-5As shown, the present embodiment provides an ultrasonic cleaning device, comprising:

[0047] Cleaning tank 2, filled with washing liquid;

[0048] The ultrasonic generating device 3 has an ultrasonic vibration end, and the ultrasonic vibration end faces the cleaning tank 2;

[0049] The water supply tank 100 communicates with the cleaning tank 2 and supplies liquid to the cleaning tank 2;

[0050] The automatic water supply device is arranged above the water supply tank 100 and communicated with the water supply tank 100. The liquid in the automatic water supply device automatically flows into the water supply tank 100 to maintain the liquid level in the water supply tank 100 at a certain height.

[0051] The ultrasonic cleaning device of this embodiment can be a countertop type, such as being placed on a sink, etc., or it can be wall-mounted, fixed on a wall, or a position suitable for installation and use such as a fixed plate, which can realize ...

Embodiment 2

[0072] Such as Figure 1-Figure 4 As shown, this embodiment is a further limitation of Embodiment 1. In this embodiment, the automatic water supply device includes a water supply box 400. The water supply box 400 is provided with a liquid outlet. When the water supply box 400 is installed above the water supply tank 100, the outlet The liquid port communicates with the water supply tank 100 ; when the liquid level in the water supply tank 100 drops below the liquid outlet of the water supply box 400 , the liquid in the water supply box 400 flows into the water supply tank 100 .

[0073] The liquid outlet of the water supply box 400 can protrude outward, or can be flush with the body of the water supply box 400, as long as the liquid level is higher than the water outlet of the water supply box 400, the liquid sealing effect can be achieved.

[0074] When the liquid in the water supply tank 100 flows into the cleaning tank 2 and at least part of the liquid outlet of the water s...

Embodiment 3

[0086] Such as figure 1 and Figure 5 As shown, the present embodiment provides an ultrasonic cleaning device, comprising:

[0087] Body 1, which is provided with a cleaning tank 2 for holding washing liquid;

[0088] Ultrasonic generating device 3, used for washing the articles in the cleaning tank 2;

[0089] The drainage device 4 includes a drainage waterway communicated with the cleaning tank 2 and a drainage control device 5 arranged on the drainage waterway to control its on-off.

[0090] Wherein, the drainage waterway includes an installation groove 6 for installing the drainage control device 5, and the installation groove 6 communicates with the cleaning tank 2; the bottom of the installation groove 6 is provided with a drain port 8, and the drainage control device 5. When pressed by external force, it moves in the installation groove 6 and cooperates with the drain port 8 to conduct the drainage waterway.

[0091] The cleaning tank 2 of this program is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com