Ceramic clay rubbing method

A clay and ceramic technology, applied in the field of ceramic clay kneading, can solve the problems of uneven mixing and singleness, and achieve the effect of good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

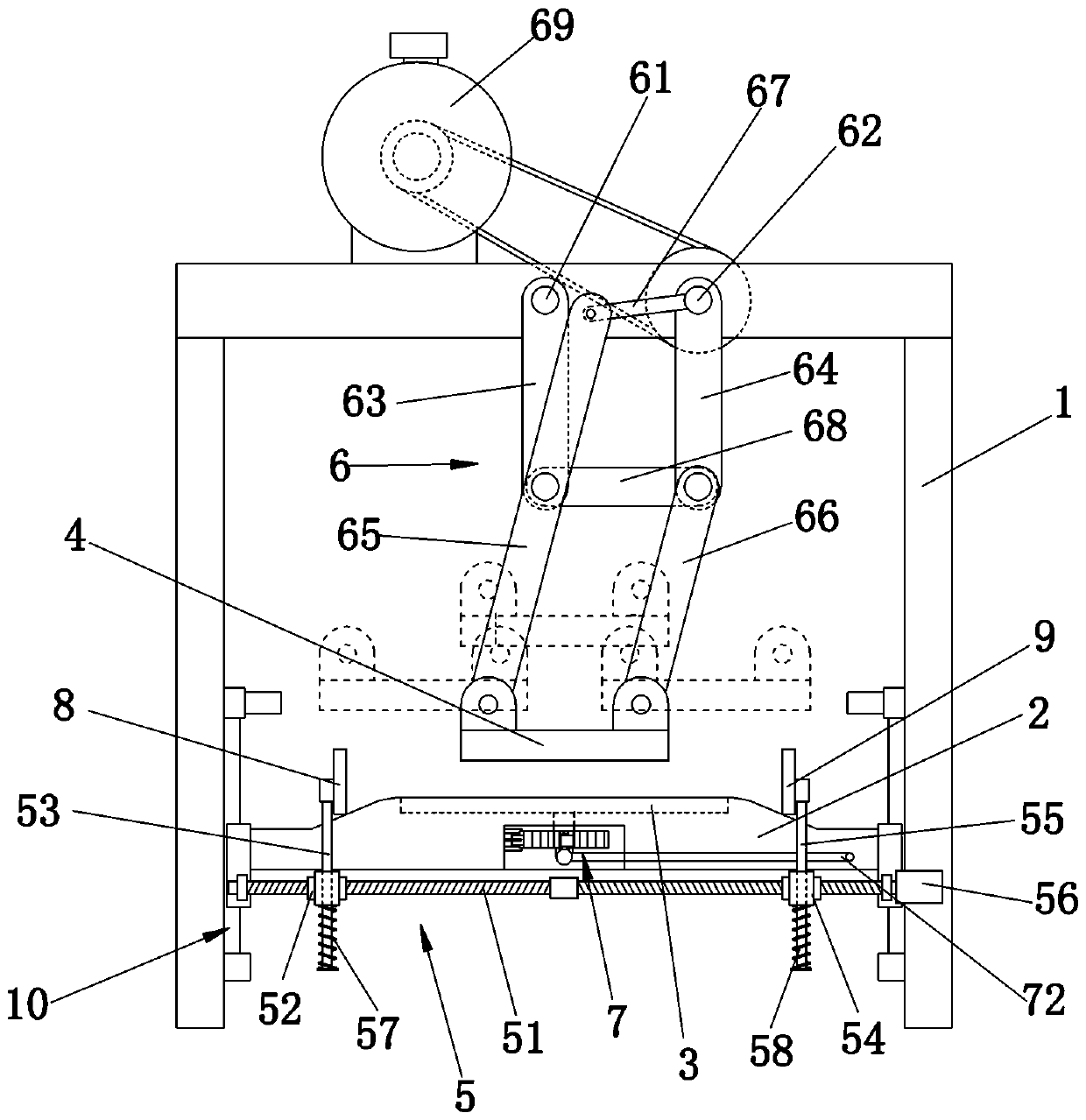

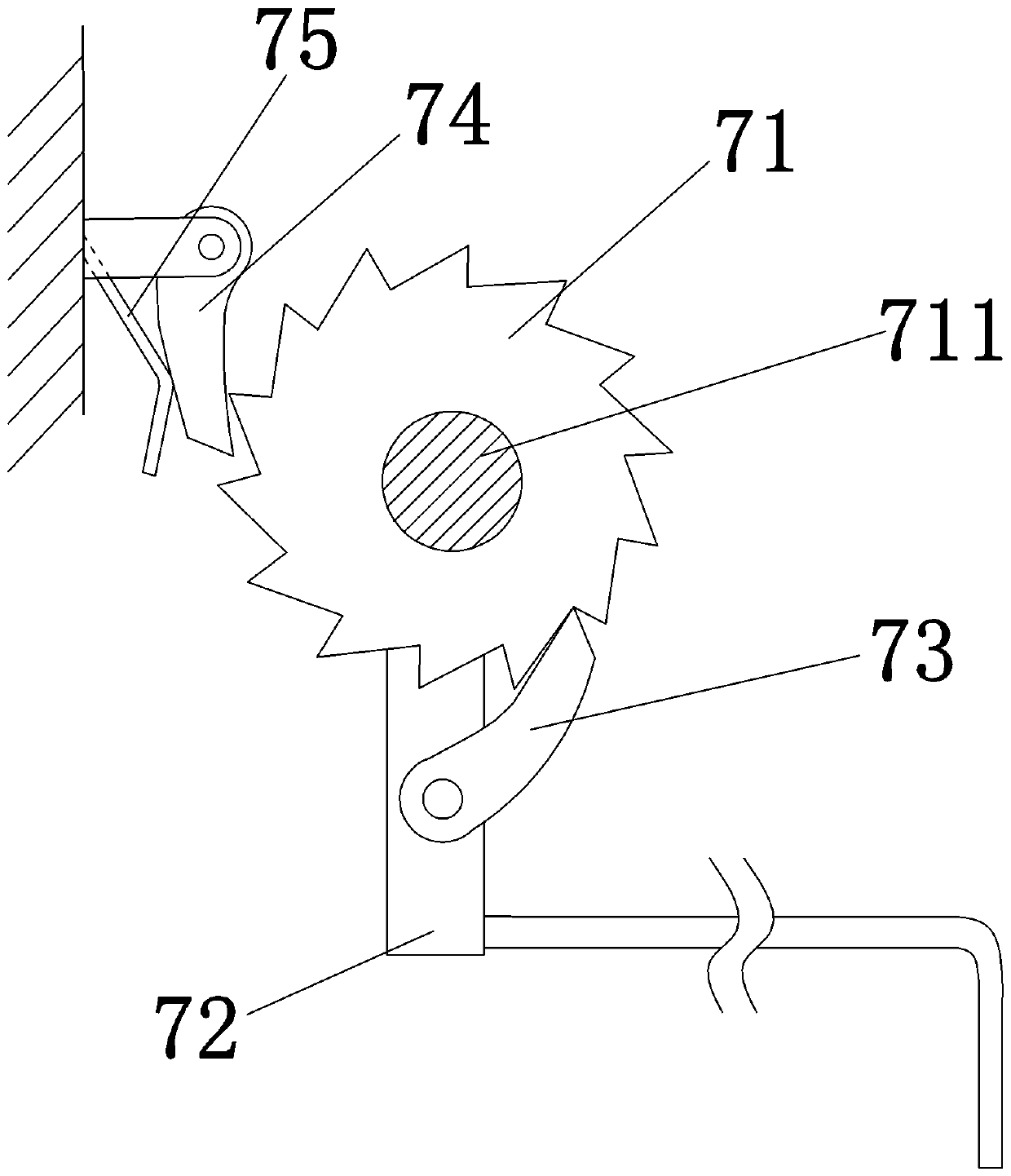

[0027] refer to figure 1 and figure 2 , a ceramic clay processing equipment, including a frame 1, a workbench 2, a turntable 3, an upper platen 4, a screw slide drive mechanism 5, a multi-link drive mechanism 6, a ratchet drive mechanism 7, a left platen 8 and a right platen 9. A numerically controlled sliding table 10 is installed on the pole of the frame 1 , and the left and right ends of the workbench 2 are arranged on the frame 1 through the numerically controlled sliding table 10 to move up and down. The middle part of the upper end face of the workbench 2 is a horizontal plane, and the left and right sides are inclined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com