Vehicle body transfer system suitable for multi-vehicle production

A multi-model, body technology, applied in the direction of motor vehicles, load suspension components, injection devices, etc., can solve problems such as inability to meet, single model, improve production efficiency and quality, and meet the requirements of intelligent, safe and reliable production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

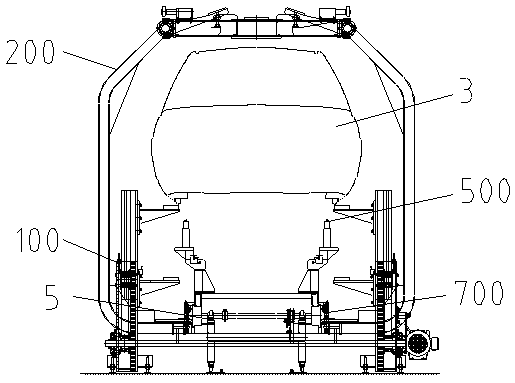

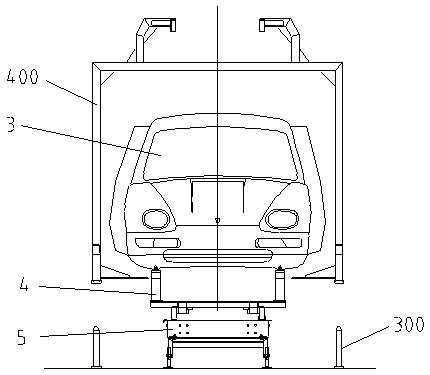

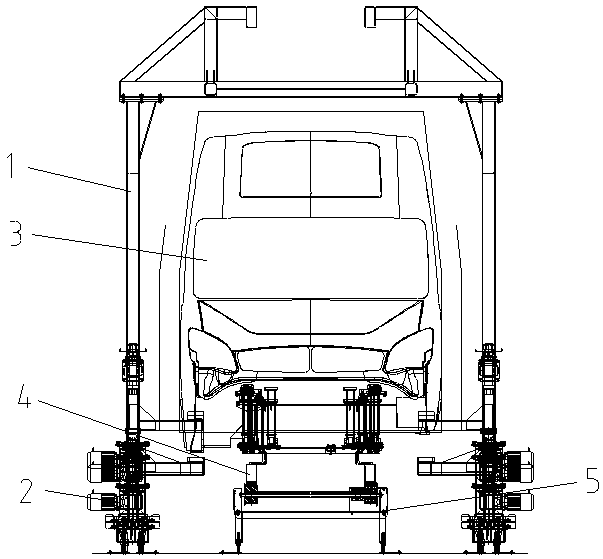

Image

Examples

Embodiment 1

[0058] Please see attached Figure 11 , No. ① model of serial number 1 adopts two sets of fixed support arms 14 and two groups of rotating support arm assemblies 13 before and after to form the lifting form of four support points 7 on each side.

Embodiment 2

[0060] Please see attached Figure 12 , the ⑤ car model of serial number 10 adopts two groups of fixed bracket arms 14 and a group of rotating bracket arm assemblies 13 at the front to form the lifting form of three support points 7 on each side.

Embodiment 3

[0062] Please see attached Figure 13 , the ⑤ model of serial number 16 adopts two sets of fixed support arms 14 and a group of rotating support arm assemblies 13 in the middle to form the lifting form of three support points 7 on each side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com