Crane load oscillation reducing system

A technology for cranes and machine bases, which is applied in the field of vibration reduction systems for crane loads, and can solve problems such as spending more time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The implementation of the present invention is described below by means of specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. In addition, the present invention can also be implemented or applied through other different specific embodiments, and various modifications and changes can be made without departing from the spirit of the present invention.

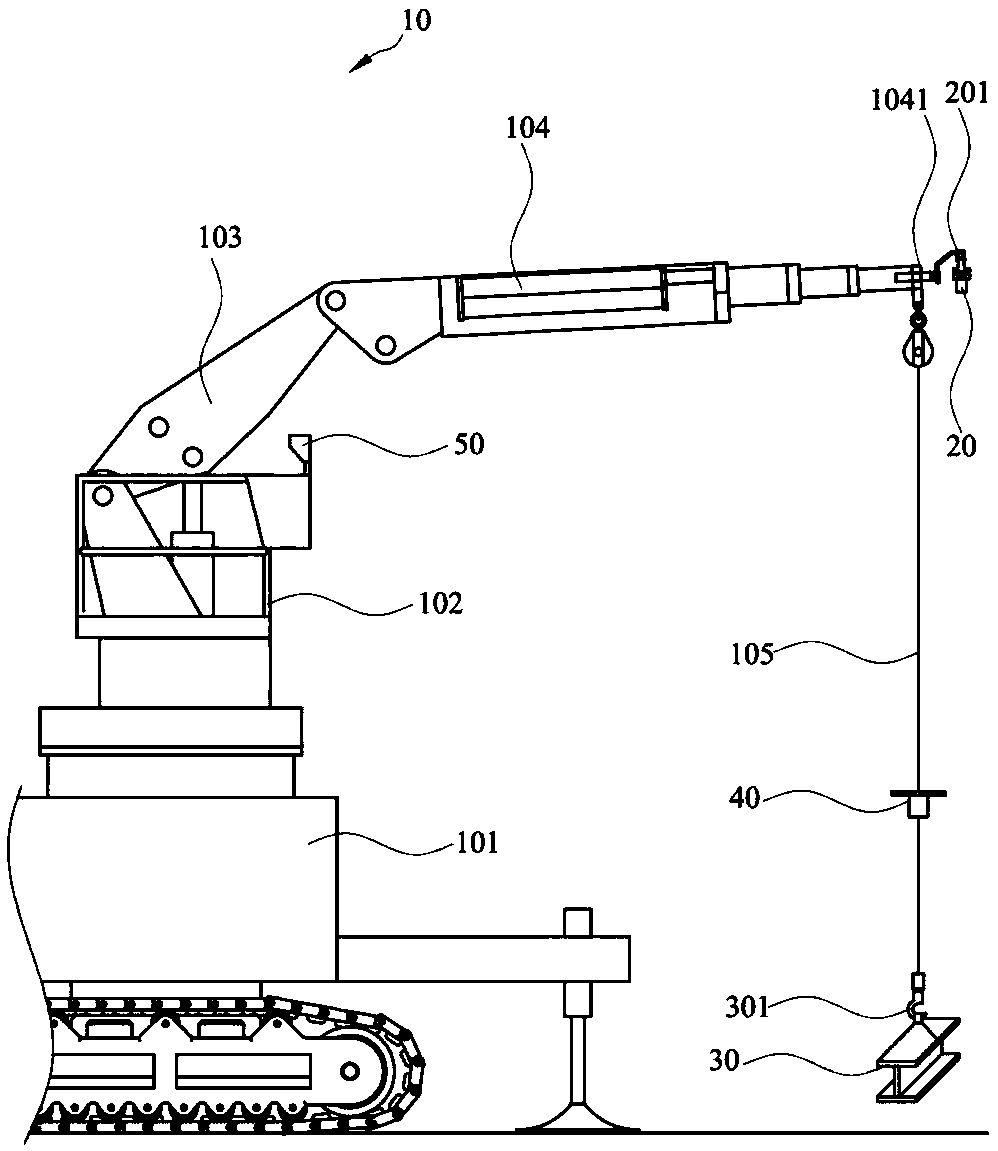

[0053] Please refer to figure 1 as shown, figure 1 It is a schematic diagram of the anti-sway system of the crane load of the present invention.

[0054] Such as figure 1 As shown, the present invention provides a crane load damping system 1 , including: a crane 10 , a smart camera 20 , a load 30 , an indicator 40 and a guide interface 50 . First, the crane 10 includes a base 101, a fixed frame 102, a forearm 103, a boom 104 and a suspension line 105, the fixed frame 102 is installed on the base 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com