Deviation correction device for tube-sinking cast-in-situ pile and use method thereof

A technology of sinking tube grouting piles and deviation correction devices, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., to achieve the effects of improving friction, realizing sinking tube deviation correction, and improving accuracy and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

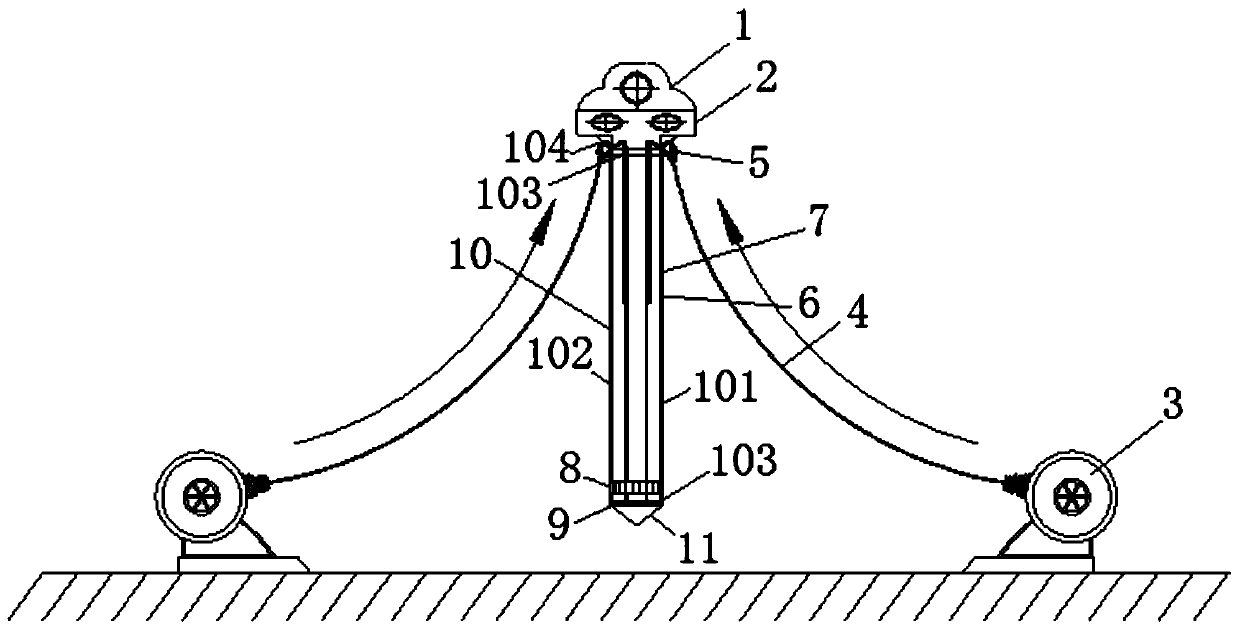

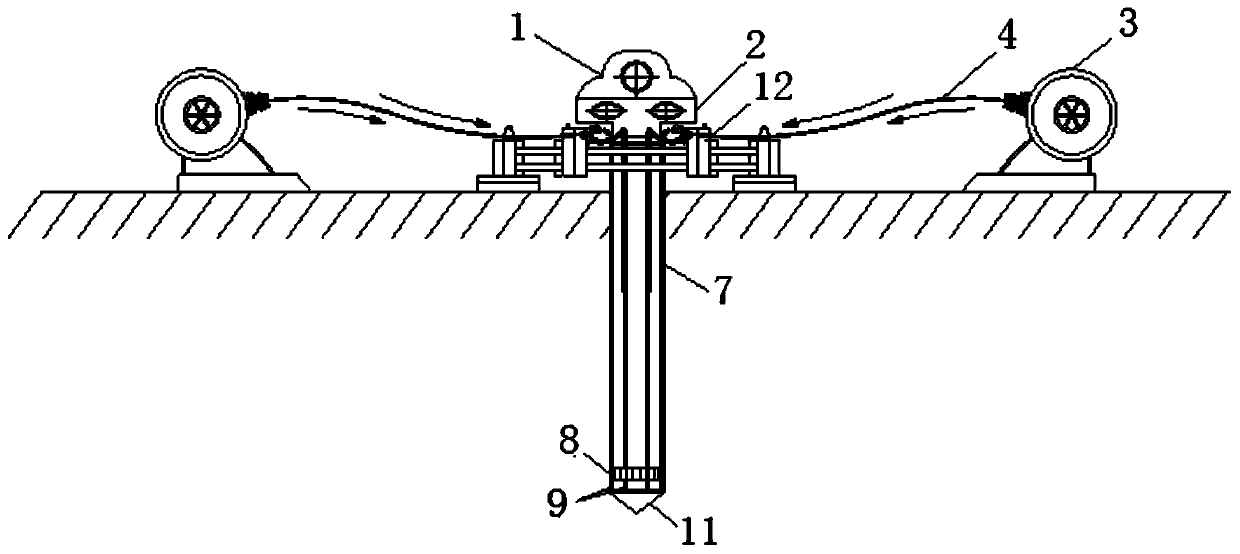

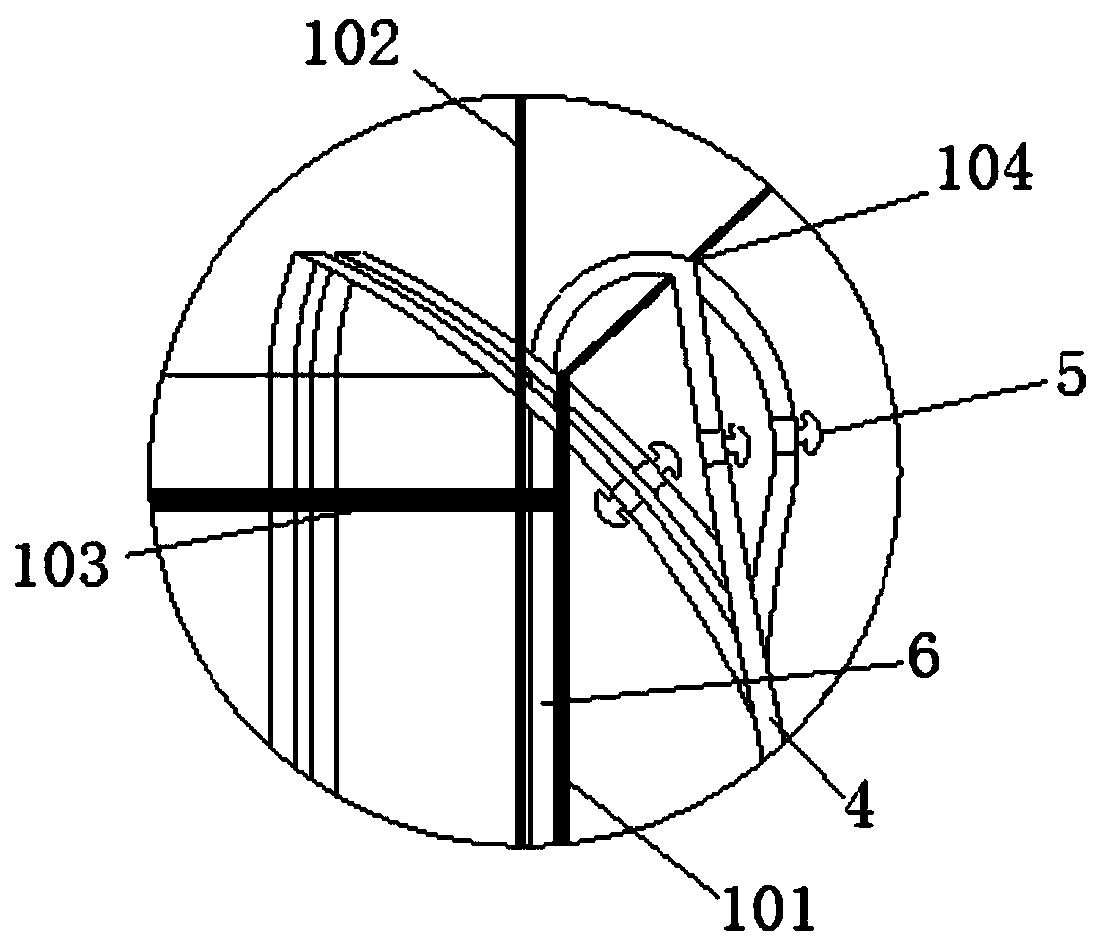

[0068] A deviation correcting device for immersed pipe cast-in-situ piles according to the present invention, comprising a double-action steam hammer 1, a hammer pad 2, a high-pressure fan 3, an air guide main pipe 4, an air flow control valve 5, an air guide branch pipe 6, and an expansion and contraction air cushion 7. Pneumatic device 8, lifting sleeve 9, pipe top deviation correcting device 12 and angle measuring device 13;

[0069] The double-action air hammer 1 is arranged on the top of the immersed tube 10, the output end of the double-action air hammer 1 is fixedly connected with the upper end of the hammer pad 2 vertically downward, and the lower end of the hammer pad 2 is fixedly connected with the top of the immersed tube 10; The air hammer in the air hammer 1 can move up and down in its shell, and hammer the top of the sinking tube through the hammer pad 2; the impact frequency of the double-action air hammer 1 is high, and after the pile filling is completed, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com