Heating cooker

A cooker and heating chamber technology, which is applied in the directions of heating method, electric heating fuel, lighting and heating equipment, etc., can solve the problem that the temperature of the front panel of the grilling door cannot be lowered sufficiently, and it is difficult to fully ensure that the front panel of the grilling door and the front panel are maintained. Part distance and other issues to achieve the effect of improving the cooling effect and suppressing the heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]

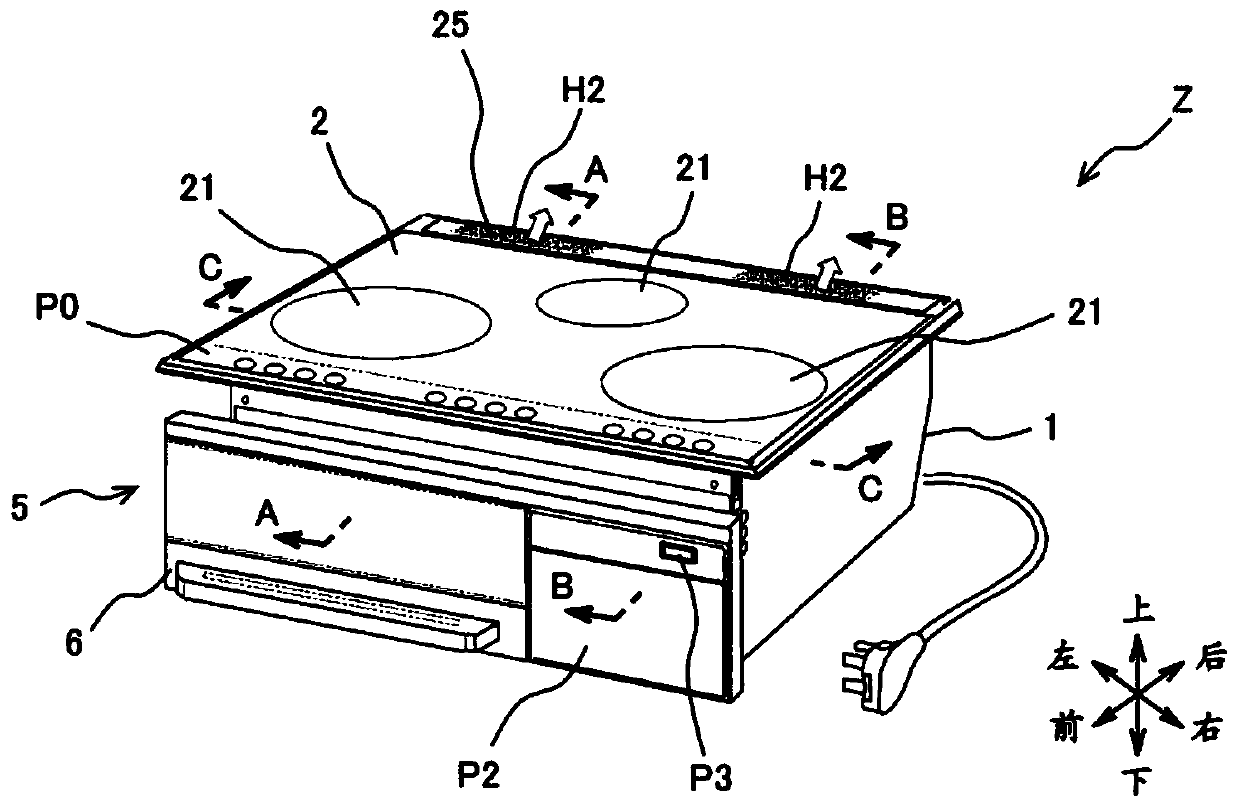

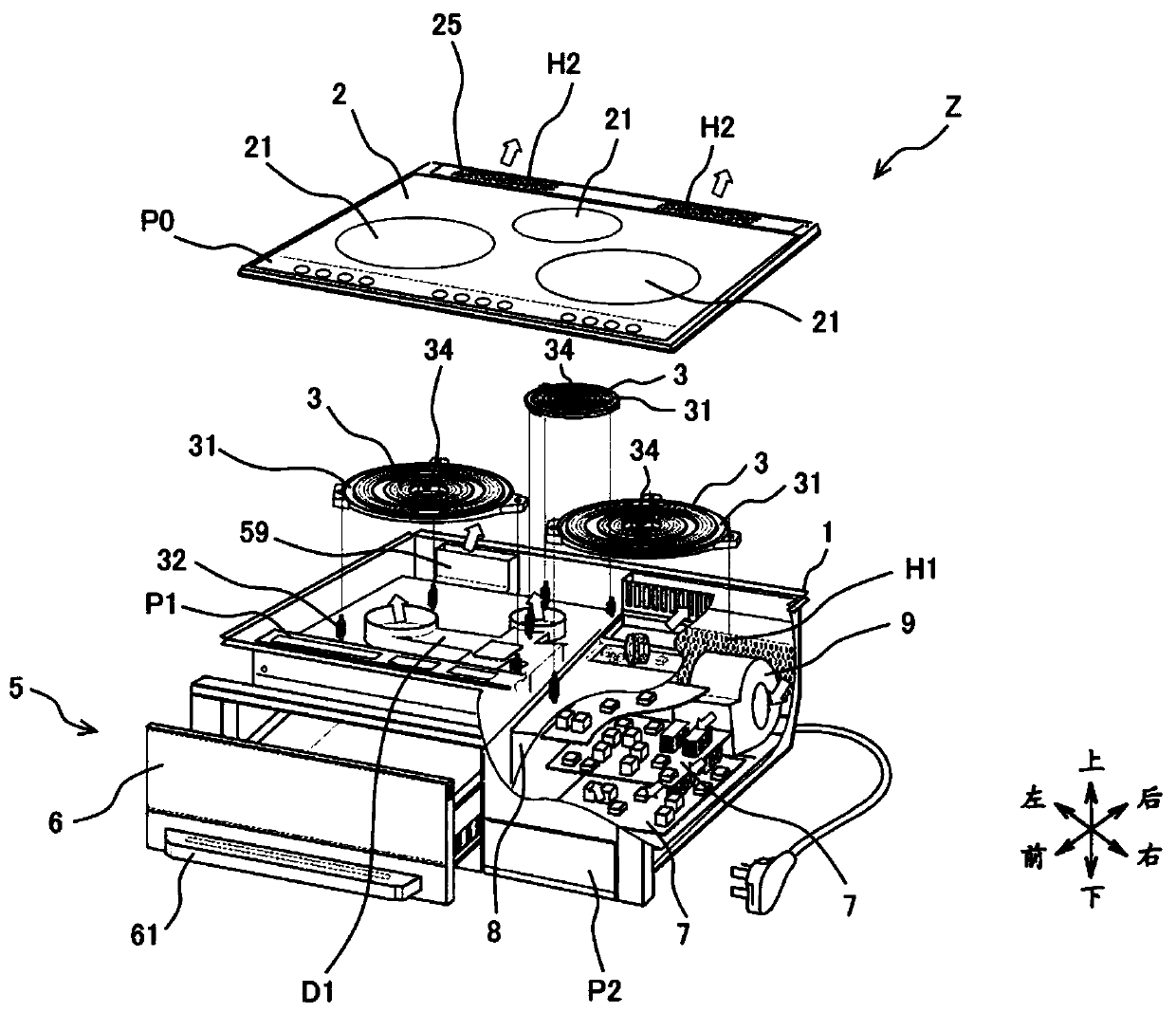

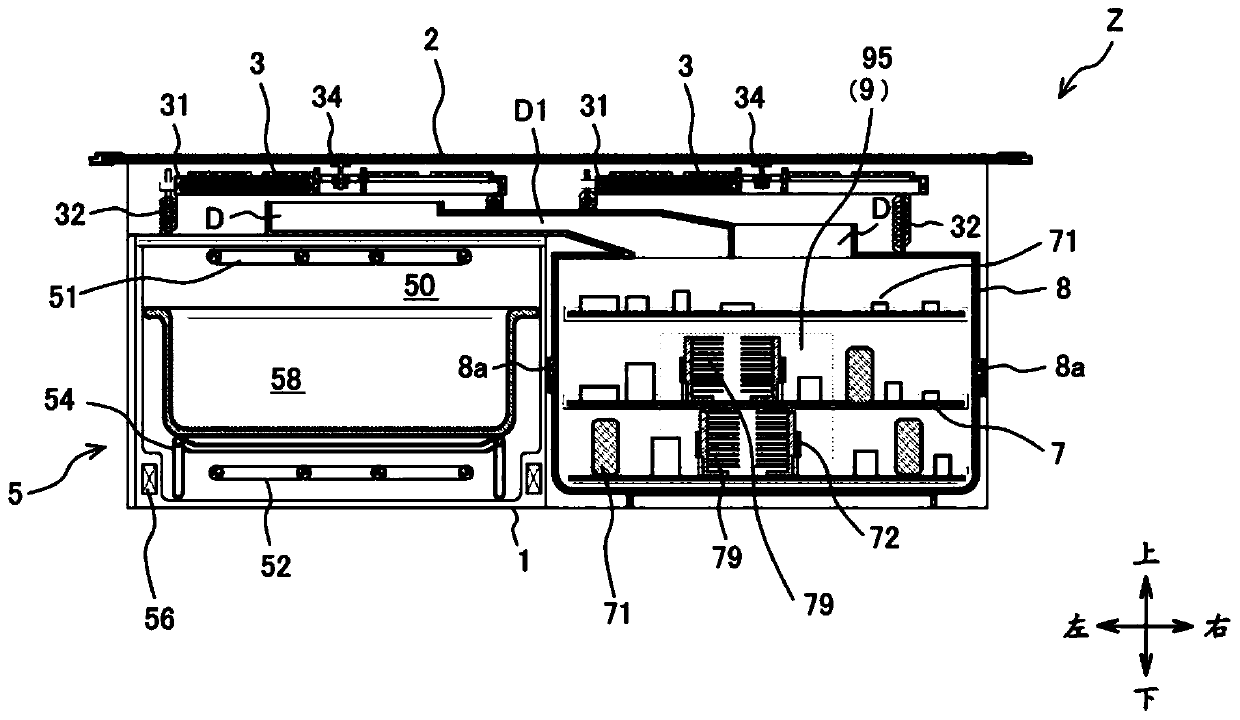

[0035] figure 1 It is the perspective view of the heating cooker Z of Example 1 of this invention, figure 2 yes figure 1 The exploded perspective view of image 3 is in figure 1 The front sectional view taken at the line C-C shown, Figure 4 is in figure 1 A side sectional view taken at the line A-A shown, Figure 5 yes Figure 4 schematic diagram.

[0036] The heating cooker Z of Example 1 generates eddy currents in the bottom of a metal cooking pot (not shown), and the Joule heat generated by the eddy current causes the cooking pot itself to generate heat.

[0037] figure 2 Among them, the above-mentioned eddy current is generated by flowing a high-frequency current of, for example, about 20 kHz to 40 kHz to the heating coil 3 and changing the magnetic flux with time. The heating cooker Z mainly includes a main body 1 , a top plate 2 , a heating coil 3 , a substrate case 8 , and a grill oven 5 .

[0038] The main body 1 is a box having an outer contour...

Deformed example 1

[0068] Next, use Figure 7 Modification 1 of Embodiment 1 will be described. Figure 7 It is a figure which shows the modification 1 of a door part.

[0069] exist Figure 7 In Modification 1 shown, the lower part of the frame 62 is recessed upward. Furthermore, the upper end of the front panel 60 is supported by the frame 62 , and the lower end of the front panel 60 is supported by the door base 61 . An air intake opening 62b is formed at the lower end of the door base 61 and the recessed portion of the frame 62 . According to the modified example, the opening area of the intake opening 62b can be easily enlarged. In addition, when viewed from the front, the air intake opening 62b is hidden by the door base 61, thereby improving designability.

[0070]

[0071]Next, the flow of air in the door portion will be described. Figure 8 It is a perspective view of the integrated kitchen 100 in which the heating cooker Z is incorporated. In the integrated kitchen 100 , the...

Deformed example 2

[0079] Next, modification 2 will be described. Figure 9 is showing Figure 5 The figure of modification 2 of the broiling oven. Figure 9 in, with Figure 5 The difference is that the front plate 60 of the door portion 6 is formed of a thinner sheet-like resin. For the material of the front panel 60, the front side of the integrated kitchen 100 ( Figure 8 Compared with the accommodating part 101 etc.) of the appearance, the materials and colors of the appearance are coordinated, and an appearance design with a high sense of unity with the overall kitchen can be easily applied.

[0080] In addition, the front plate 60 of the door 6 may be made of a thin sheet-like resin. According to the modified example, the door base 61 and the front panel 60 can be integrally formed to reduce the number of parts, thereby achieving both design and assemblability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com