Extractor hood convenient to clean

A range hood and cleaning technology, applied in the removal of oil fume, heating method, household heating and other directions, can solve the problems of inability to quickly disassemble by itself, obstacles to users' daily cleaning, and many dead spots in cleaning, to protect the electronic control part and wiring, The effect of simplified structure and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

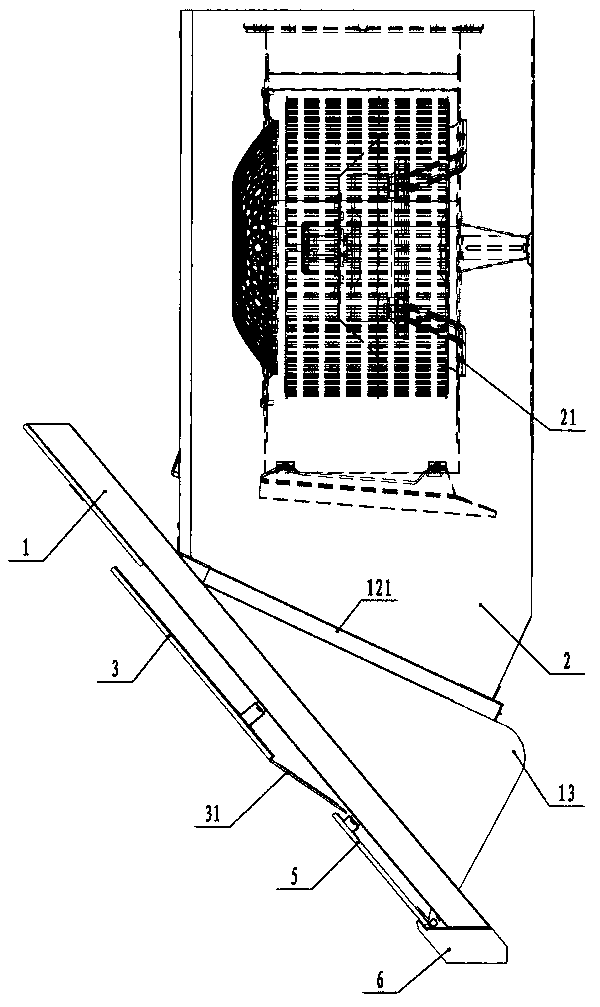

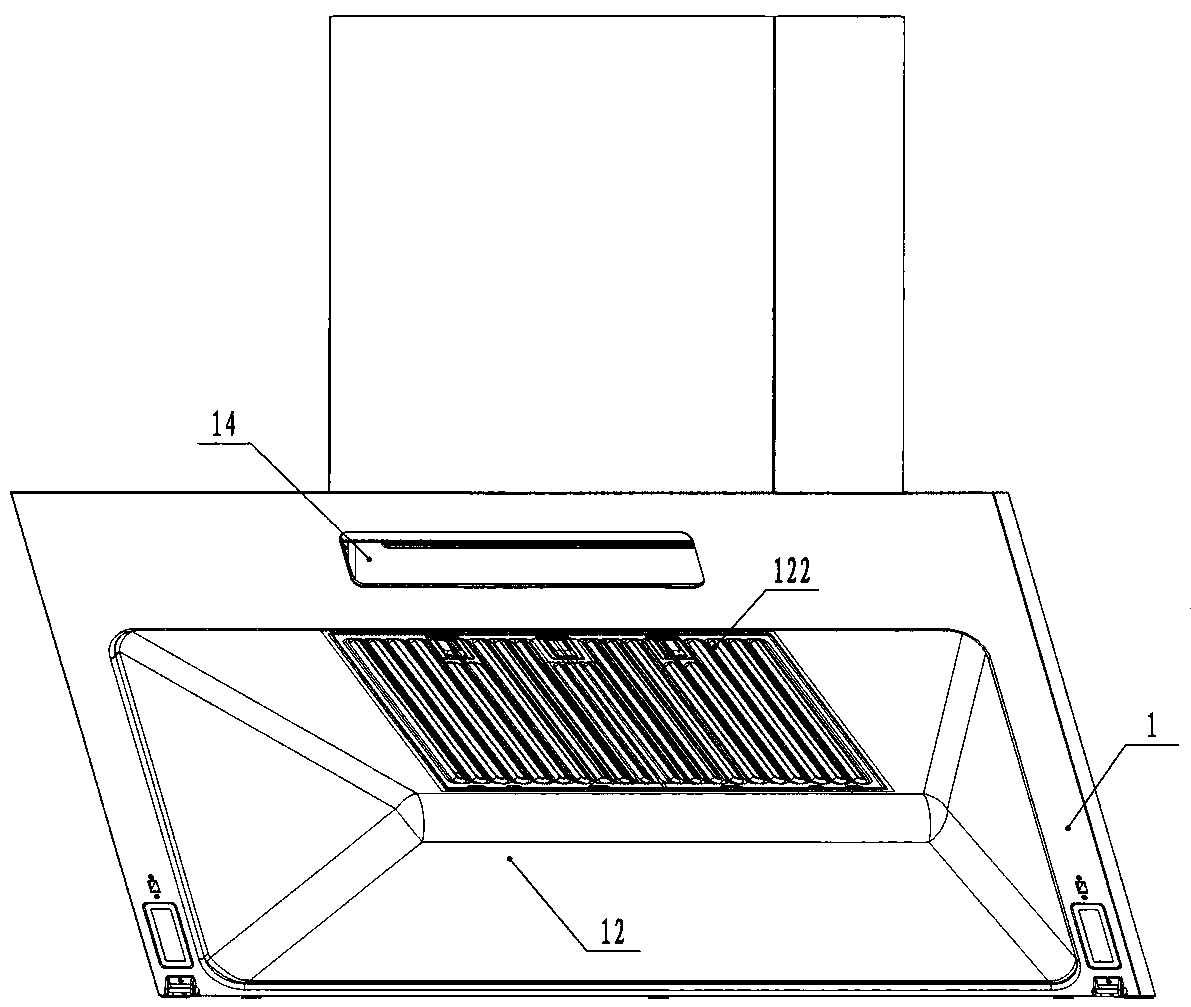

[0017] refer to Figure 1 to Figure 2 , a convenient and clean range hood, comprising a panel 1 and a chassis 2, the surface of the panel 1 is equipped with a condensing plate 3, and in a normal installation state, the panel 1 and the horizontal plane form a certain angle of inclination, the chassis 2 A fan system 21 is installed, and the panel 1 is provided with a smoke collection cavity 12 integrally formed with the panel 1. The smoke collection cavity 12 is a concave structure, and an air inlet 121 is opened on the upper stretching surface, and the smoke collection cavity 12 passes through The air inlet 121 is directly connected with the chassis 2 . The oil tank 6 is placed below the panel 1, and the oil dirt filtered and condensed by the blower fan, the filter screen and the smoke collection chamber flows into the oil tank 6 through the smoke collection chamber.

[0018] The filter screen 122 that is easy to disassemble is installed on the air inlet 121, and the user can ...

Embodiment 2

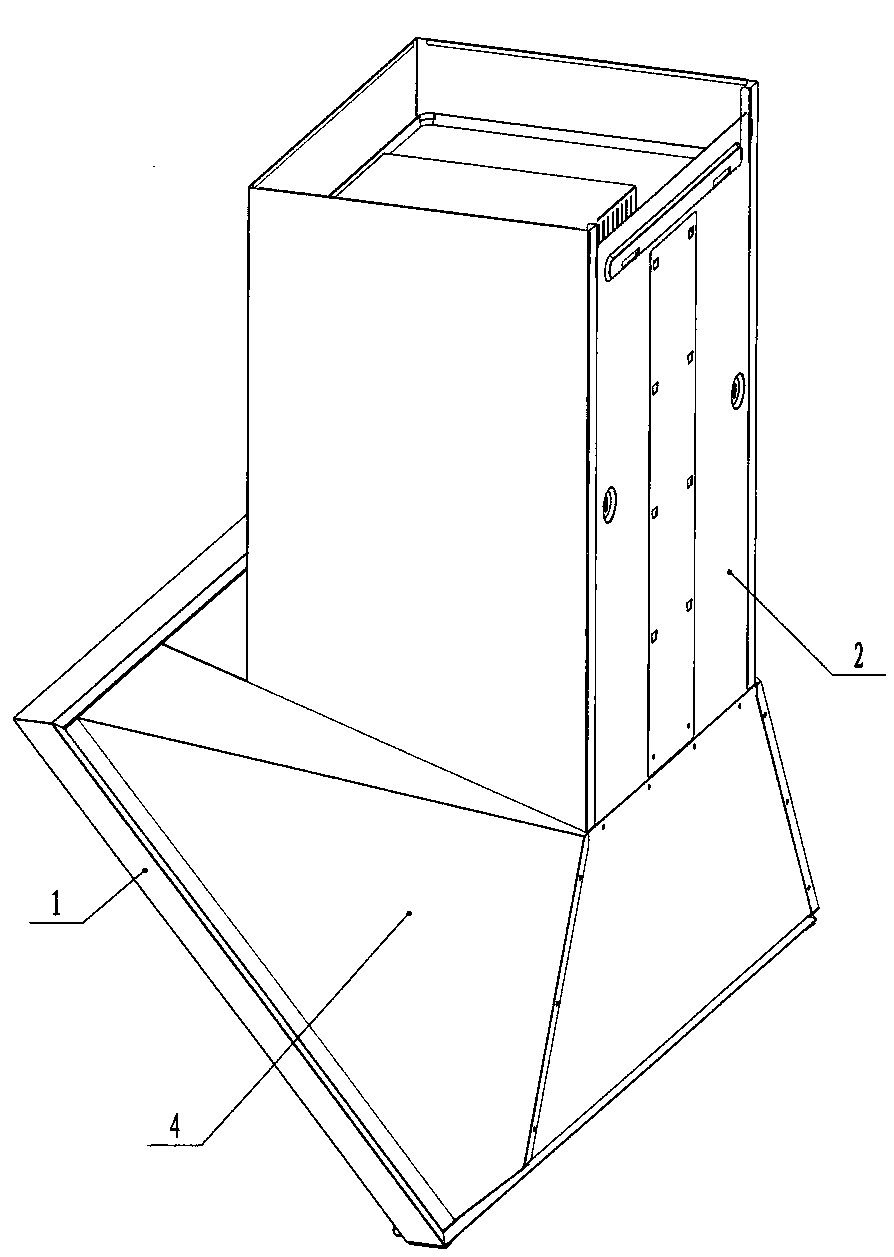

[0024] refer to image 3 The difference between this embodiment and the first embodiment is that: the back side 13 of the panel 1 is also equipped with a decorative cover 4, the part protruding from the smoke collection chamber 12 and the rivets or screws that may exist at the connection with the chassis 2 The exposed connecting parts cover it, which improves the appearance of the whole range hood to a higher level. At the same time, the space between the panel and the cover plate 4 is completely sealed, and there is no soot gas to enter, so the electric control wires arranged in the middle can be protected from corrosion, the usual electric control wires are arranged in the air duct of the chassis, and the original The electronic control part usually installed on the top of the range hood is directly installed in it, which simplifies wiring and better forms protection.

Embodiment 3

[0026] refer to Figure 4 The difference between this embodiment and the first and second embodiments is that the condensation plate 3 can also be a flap-type opening and closing structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com