Horn vibrating reed manufacturing device capable of forming and cutting and manufacturing method thereof

A technology for manufacturing devices and manufacturing methods, which is applied in the field of speaker vibrating plate manufacturing devices, can solve problems such as wire deformation, reduce the quality of vibrating plates, and affect sound quality output, so as to save the process and time of material conversion, improve processing accuracy, and improve processing. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

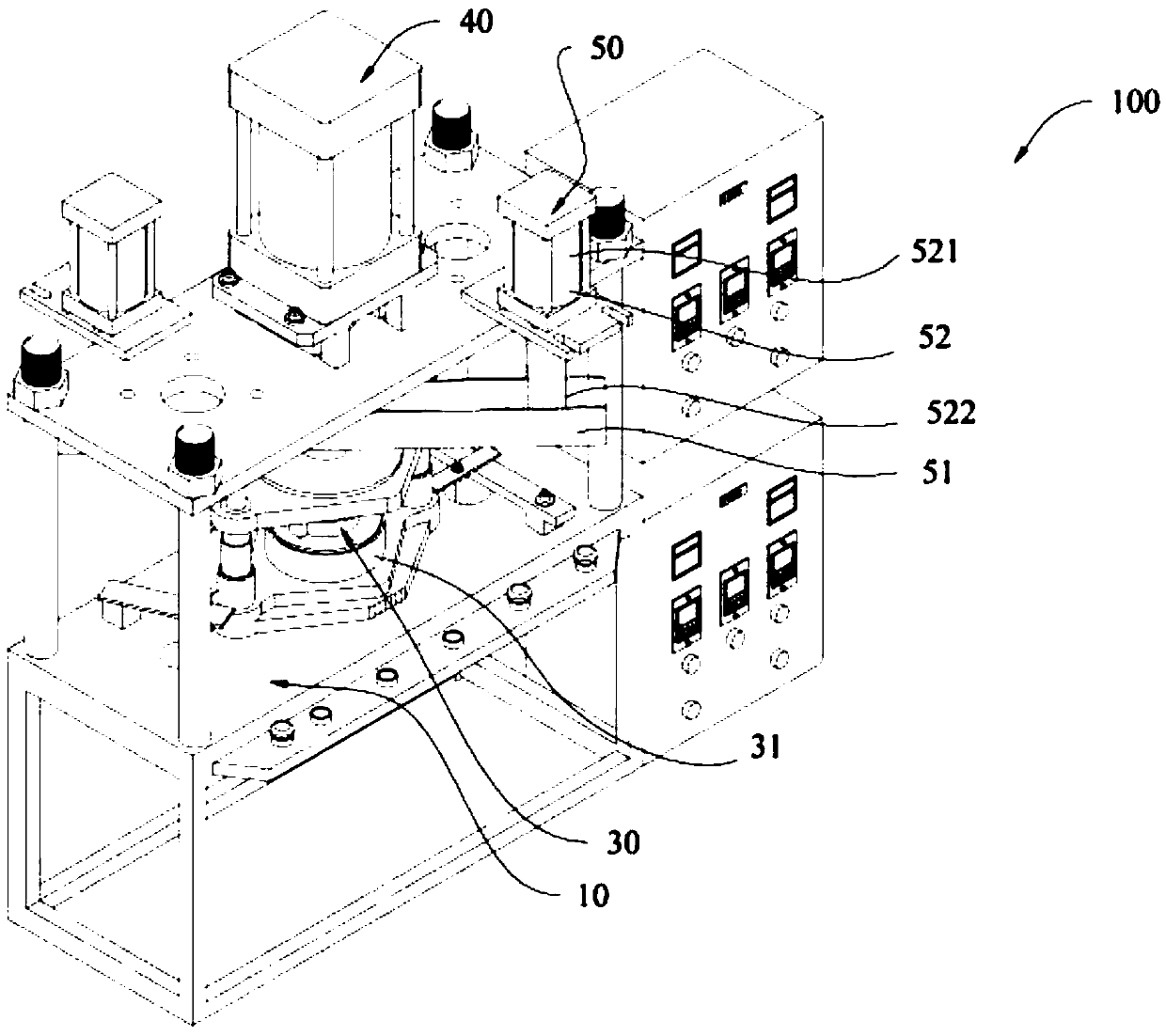

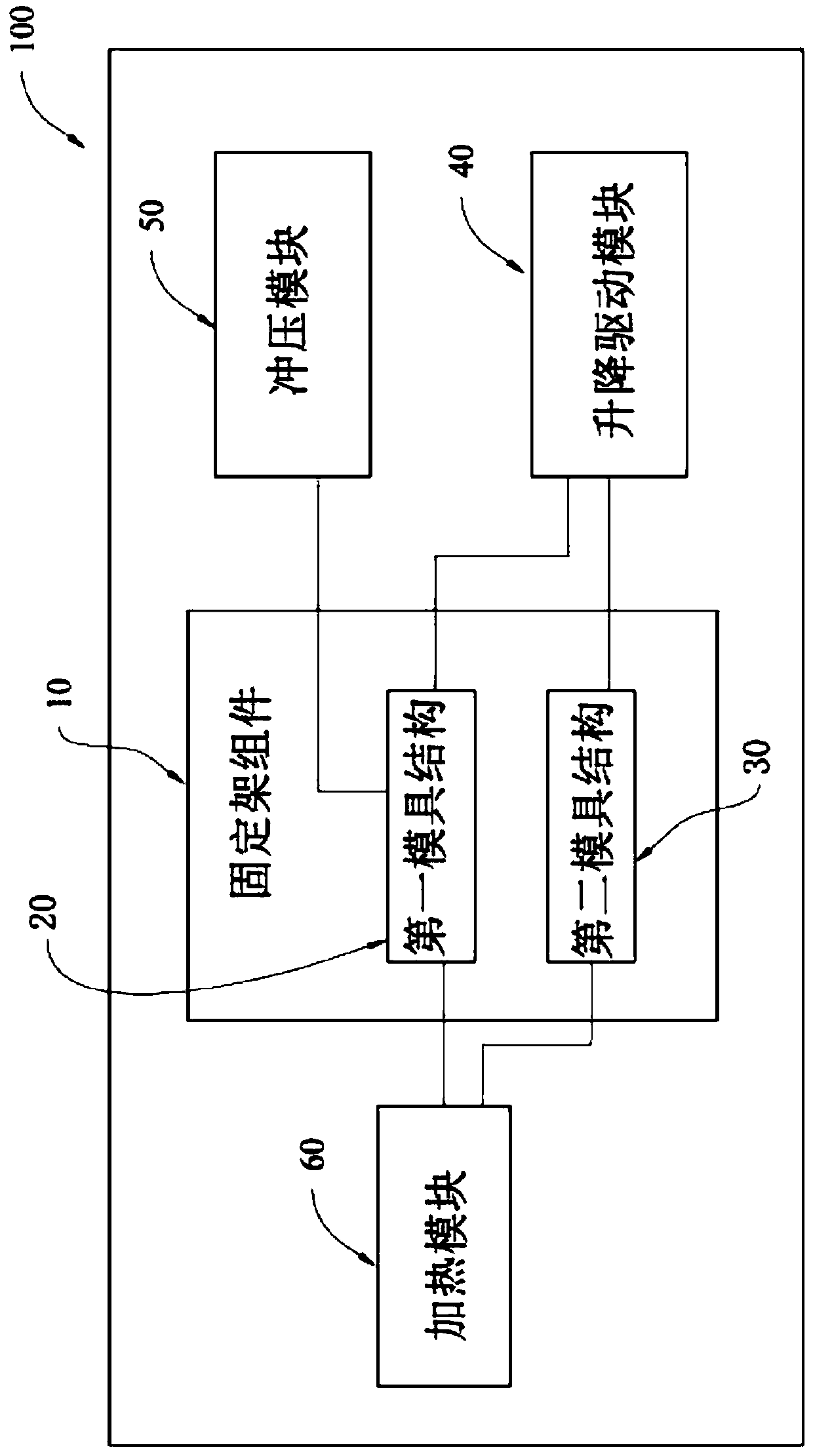

[0033] see figure 1 and figure 2 , and with Figure 3 ~ Figure 5 As shown, it is a perspective view of the device, a schematic block diagram of the device, a schematic view of the structure and a schematic view of the combination of a preferred embodiment of the present invention, which discloses a forming and cutting horn vibrating plate manufacturing device 100. The manufacturing device 100 includes:

[0034] A fixing frame assembly 10 has a fixing space 11 .

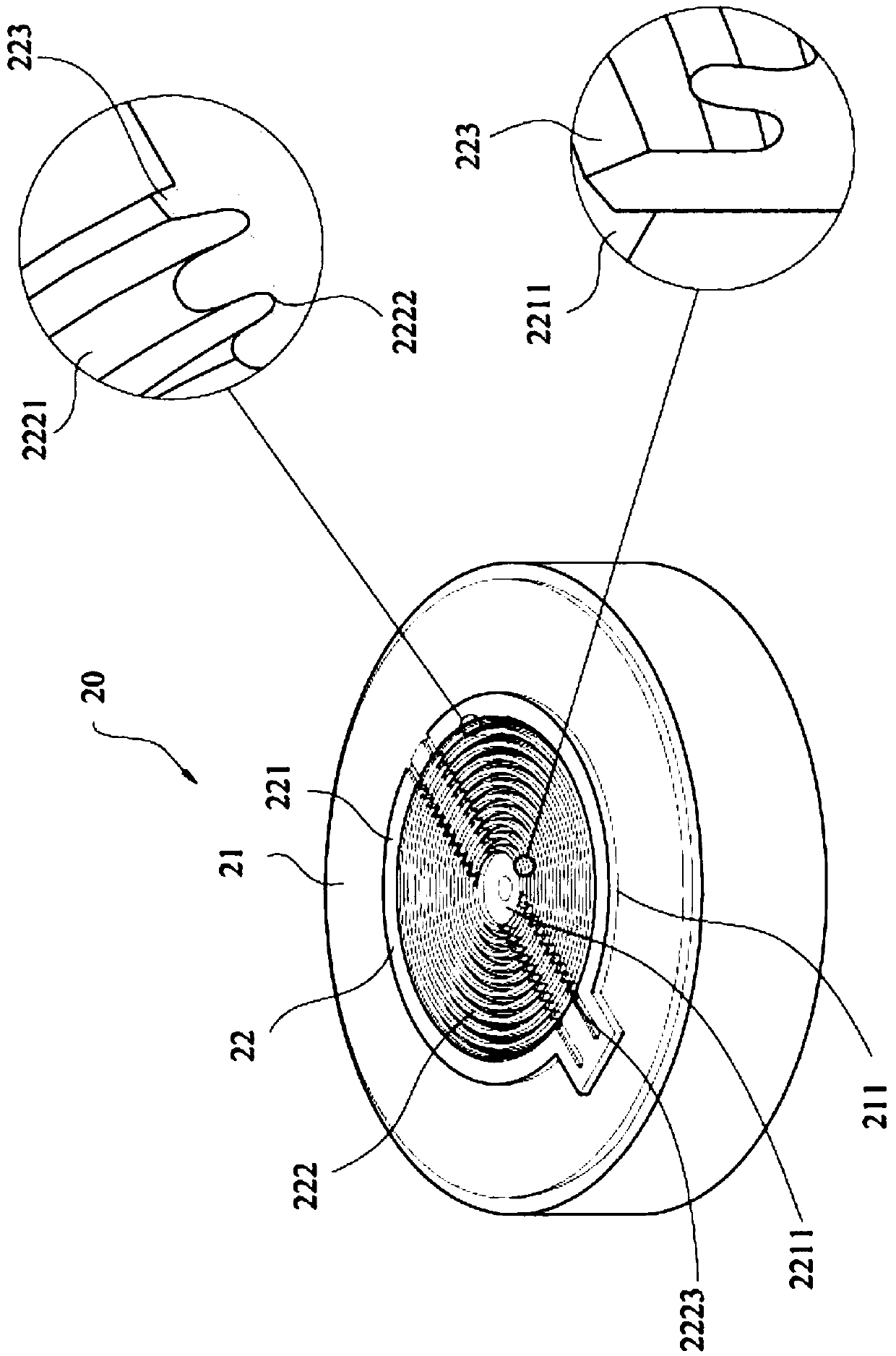

[0035]A first mold structure 20, which is arranged in the fixed space 11, is connected to the fixing frame assembly 10, and is arranged in a displaceable structure in the fixed space 11, and the first mold structure 20 has a pressing surface 221 The pressing surface 221 is convexly provided with a pressing wave portion 222, and the pressing wave portion 222 has a plurality of crests 2221 and a plurality of troughs 2222, and at least one cutting portion 223 is correspondingly formed on the top edge of a crest 2221 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com