Cuff sewing machine

A machine and body technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of low efficiency, different cuff tightness, inconsistent worker proficiency, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

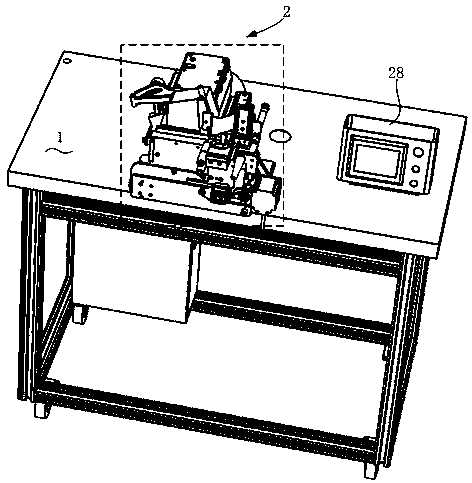

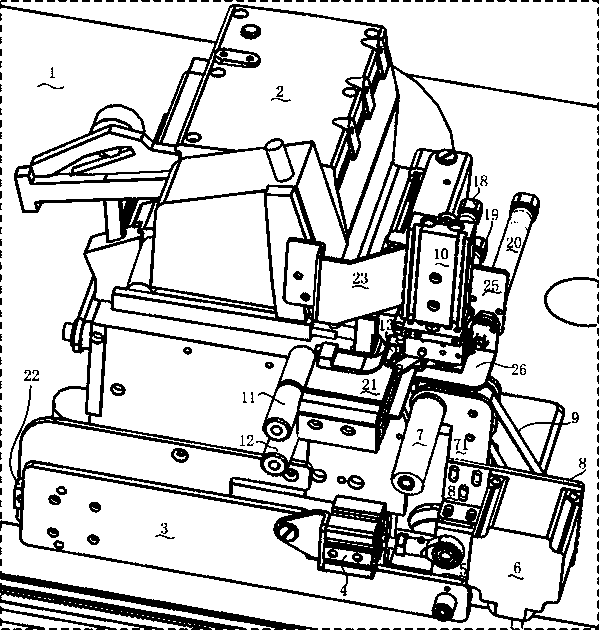

[0021] Example 1, such as Figure 1-4 The upper cuff machine shown includes a machine platform 1, on which an overlock sewing machine 2 is fixed, and the overlock sewing machine 1 has a needle board platform 21, and the first A mounting plate 3, the middle part of the first mounting plate 3 is hinged with the cylinder body of the first cylinder 4, and the end is hinged to the lower end of the support plate 5, and the support plate 5 is located on the right side of the needle plate platform 21. The cylinder rod of the first air cylinder 4 is hinged with the middle part of the support plate 5, and the top of the support plate 5 is fixedly connected with the drive motor mounting plate 8 and the drive roller mounting plate 71, and the drive motor is fixed on the drive motor mounting plate 8. 6. The driving motor shaft of the driving motor 6 is fixed with a driving synchronous pulley, and the driving roller mounting plate 71 is pivotally provided with a cloth supporting driving rol...

Embodiment 2

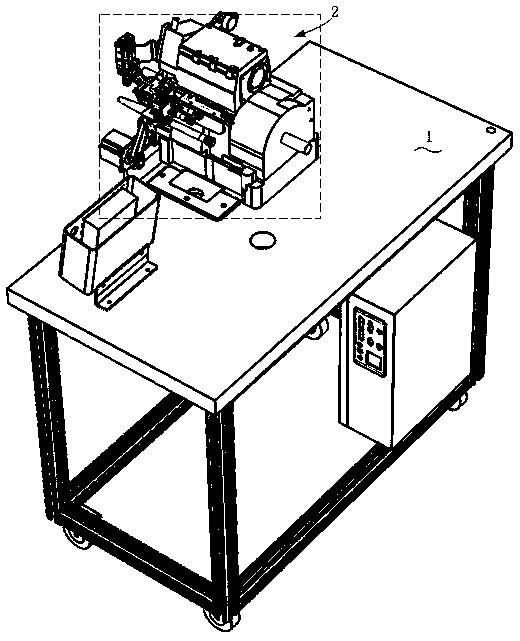

[0031] Example 2, such as Figure 5-6 Another upper cuff machine shown is different from Embodiment 1 in that the turning support mechanism includes a first mounting plate 3 arranged on the body of the overlock sewing machine 2, and the middle part of the first mounting plate 3 is hinged. The cylinder body of the first cylinder 4, the lower end of the end hinged support plate 5 are established, and the support plate 5 is positioned at the right side of the needle plate platform 21, and the cylinder rod of the first cylinder 4 is connected to the support plate 5. The middle part is hinged, and the upper part of the support plate 5 is fixedly connected to the first guide rail 51 arranged front and back, and the front end of the first guide rail 51 is fixed with an adjustment motor 53, which is slidingly matched with the first slider 52, and the motor shaft of the adjustment motor 53 is fixed. Connect the screw rod 54 whose axial direction is the front and rear direction. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com