Method and device for impregnating carbon fiber tows

A technology of carbon fiber tow and dipping device is applied in the field of carbon fiber tow, which can solve the problems of not reflecting the real value of the sample, prone to more pores in the cross section of the sample strip, affecting the accuracy of the test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

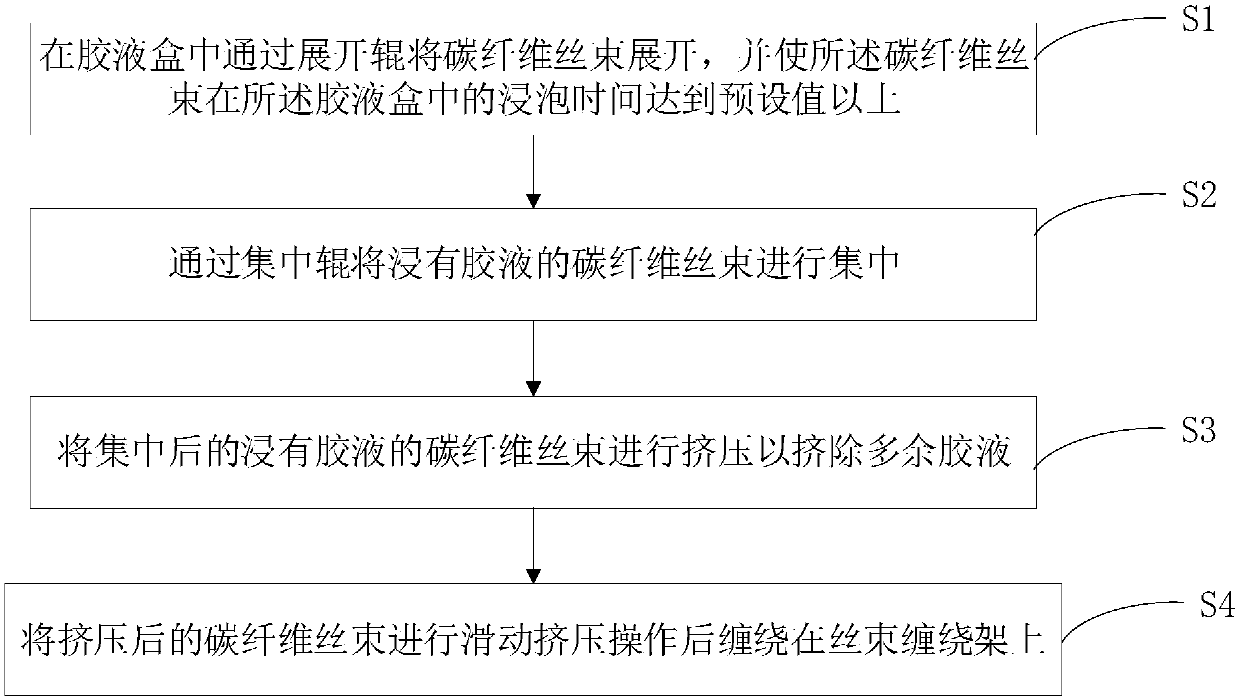

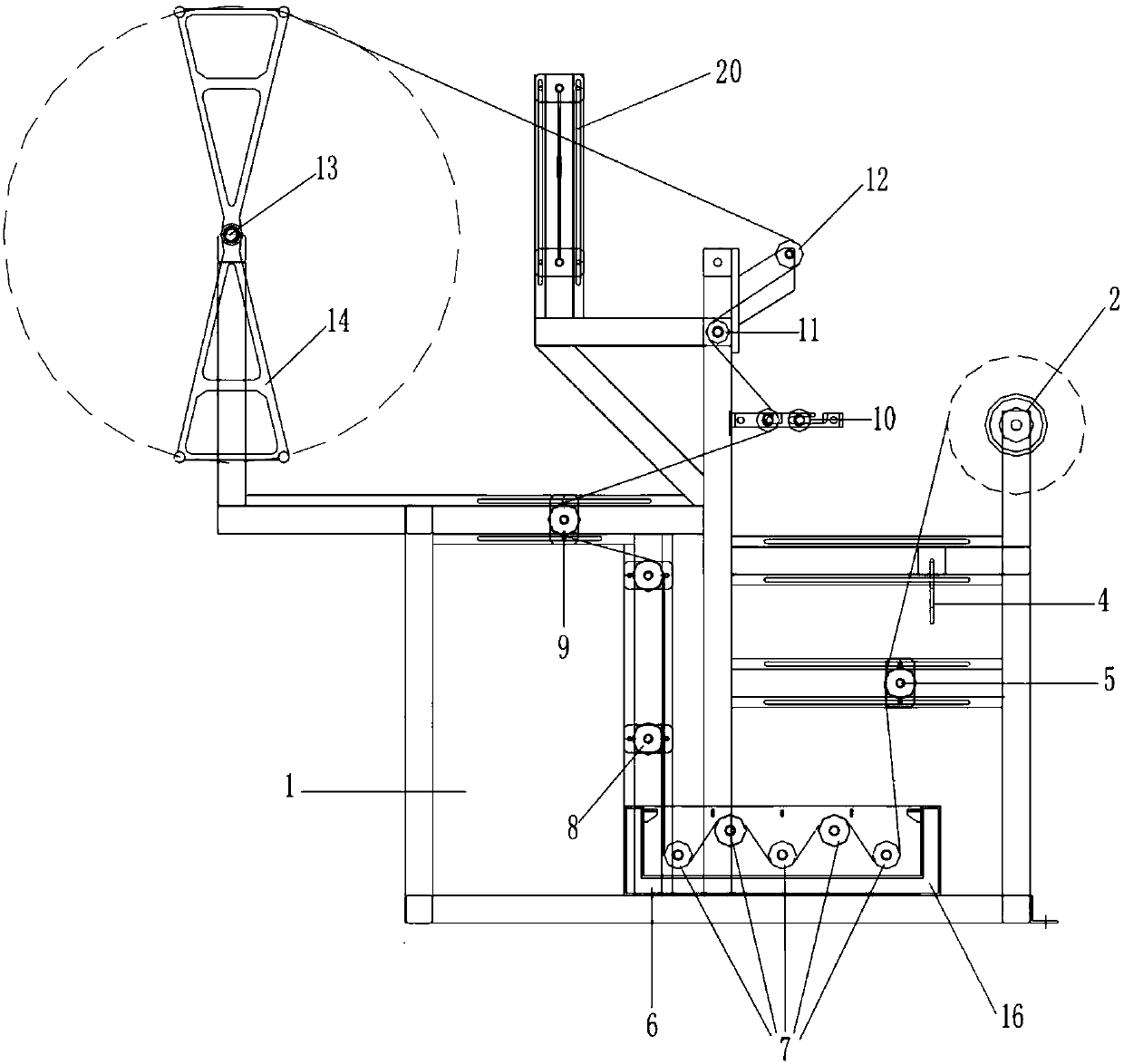

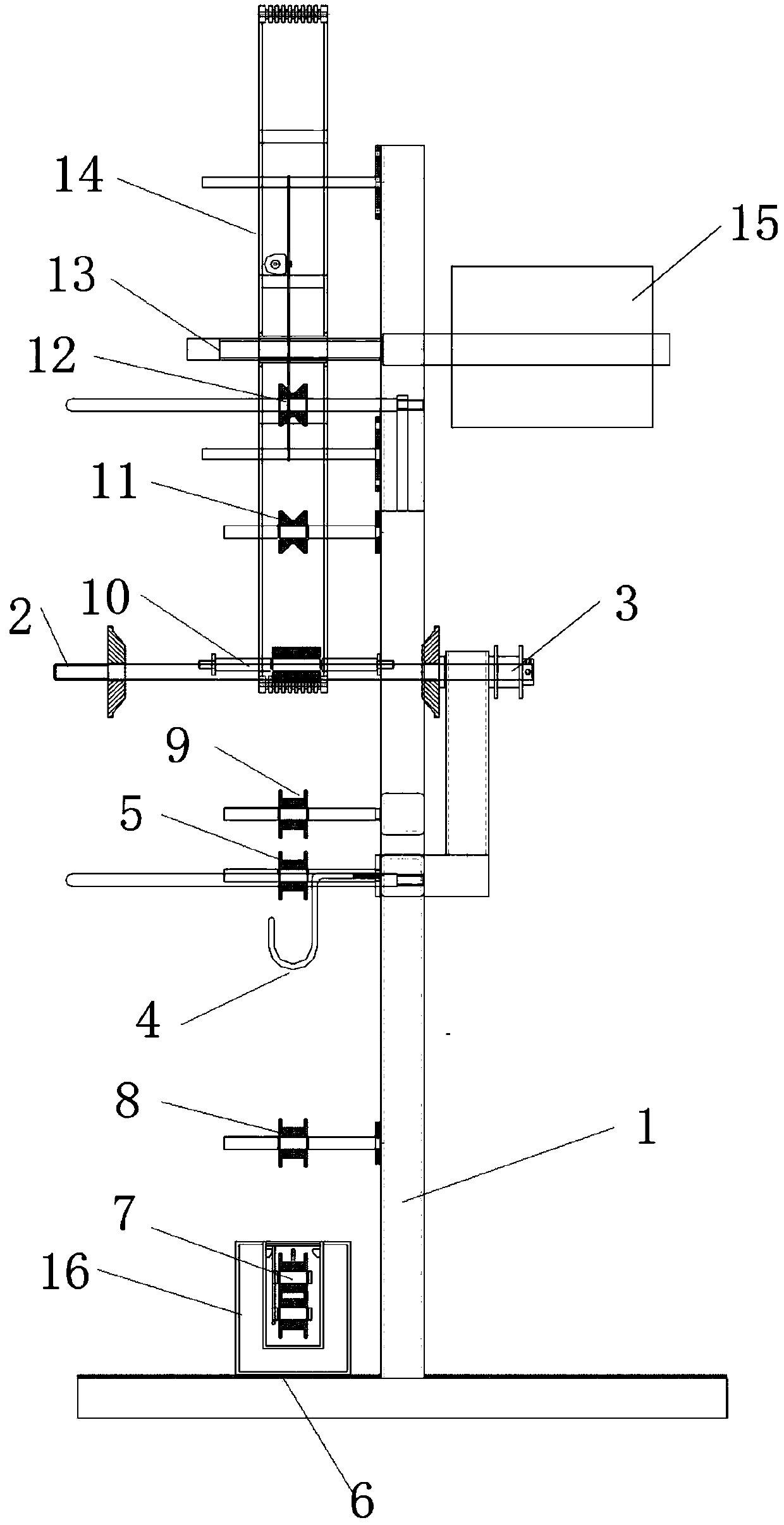

[0042] like figure 1 As shown, the invention provides a kind of dipping method of carbon fiber tow, comprising:

[0043] S1. In the glue box, the carbon fiber tow is unfolded by an unwinding roller, and the soaking time of the carbon fiber tow in the glue box reaches a preset value or more;

[0044] The preset value is 10s to 15s, preferably 12s. In order to make the immersion time of the carbon fiber tow in the glue box reach the preset value, the glue box of the corresponding length can be selected according to the speed of the tow winding frame and the preset value. More specifically, the tow winding frame is driven by a motor Rotate, its rotational speed is known, this rotational speed is converted into the traveling speed of tow and then multiplied by preset value and just can obtain the length of required glue box. In an embodiment of the present invention, the glue in the glue box is also kept at a preset temperature by means of a heat preservation device, and the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com