Connecting structure of soundproof glass curtain wall aluminum alloy and decorative strip

A technology of sound insulation glass and connection structure, applied in the direction of walls, building components, building structures, etc., can solve the problems of unreasonable connection, delay in construction period, waste of reworked materials, etc., to achieve high safety and reliability, lower project cost, and easy installation. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

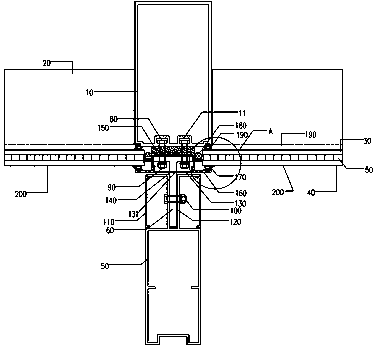

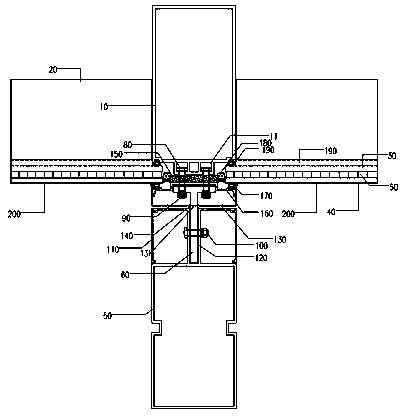

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used to explain the relative relationship between the various components in a certain posture (as shown in the drawings). When the positional relationship, movement conditions, etc., if the specific posture changes, the directional indication will also change accordingly. Furthermore, the terms "installed", "disposed", "provided", "connected", "connected", "socketed" are to be interpreted broadly. For example, it may be a fixed connection, a detachable connection, or an integral structure; it may be a mechanical connection or an electrical connection; it may be a direct connection or an indirect connection through an intermediary; internal connectivity. Those of ordinary skill in the art can understa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap