Construction method capable of quickly dismantling building component

A technology of building components and construction methods, which is applied in the direction of building structure, construction, building maintenance, etc., can solve the problems of long hoisting equipment occupation time, high clearance requirements, poor applicability, etc., and achieve a green and healthy working environment with a high degree of integration , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

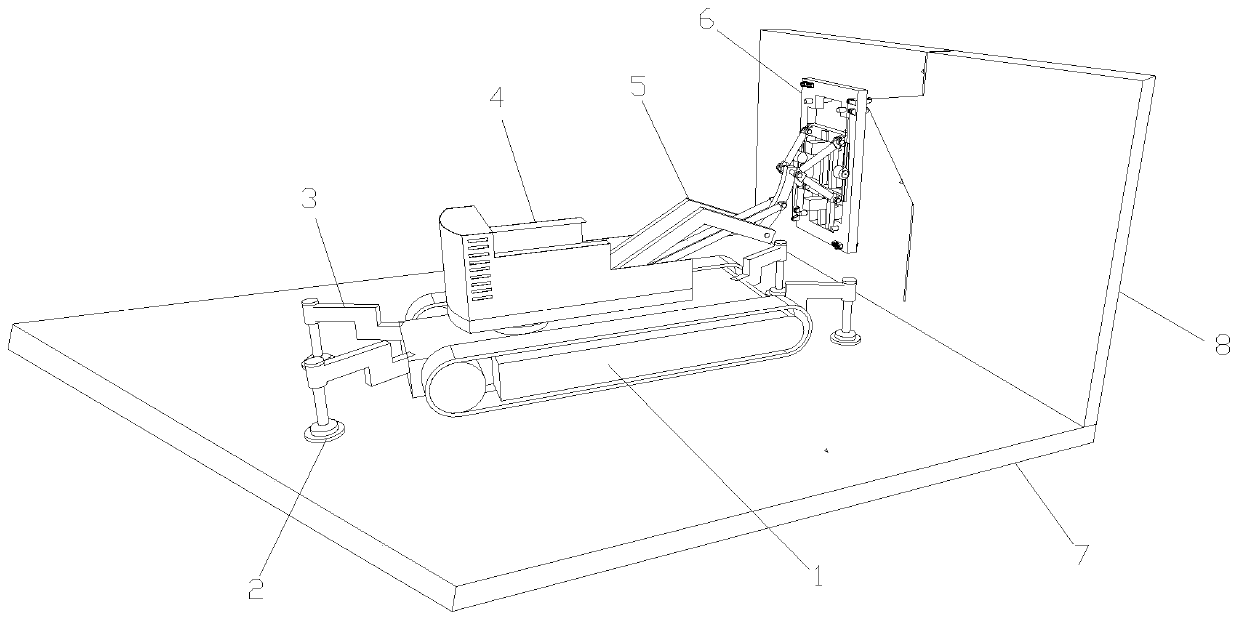

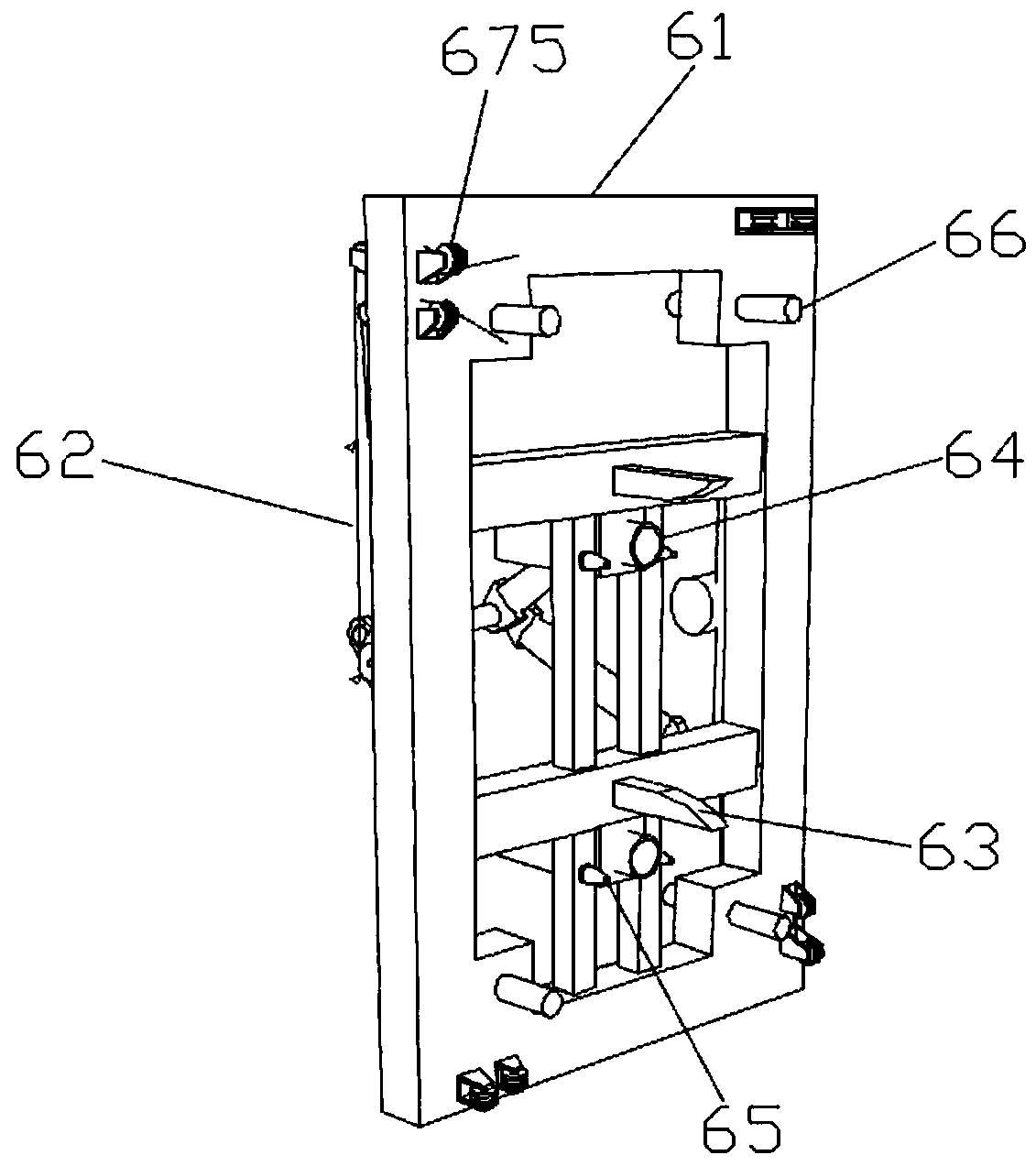

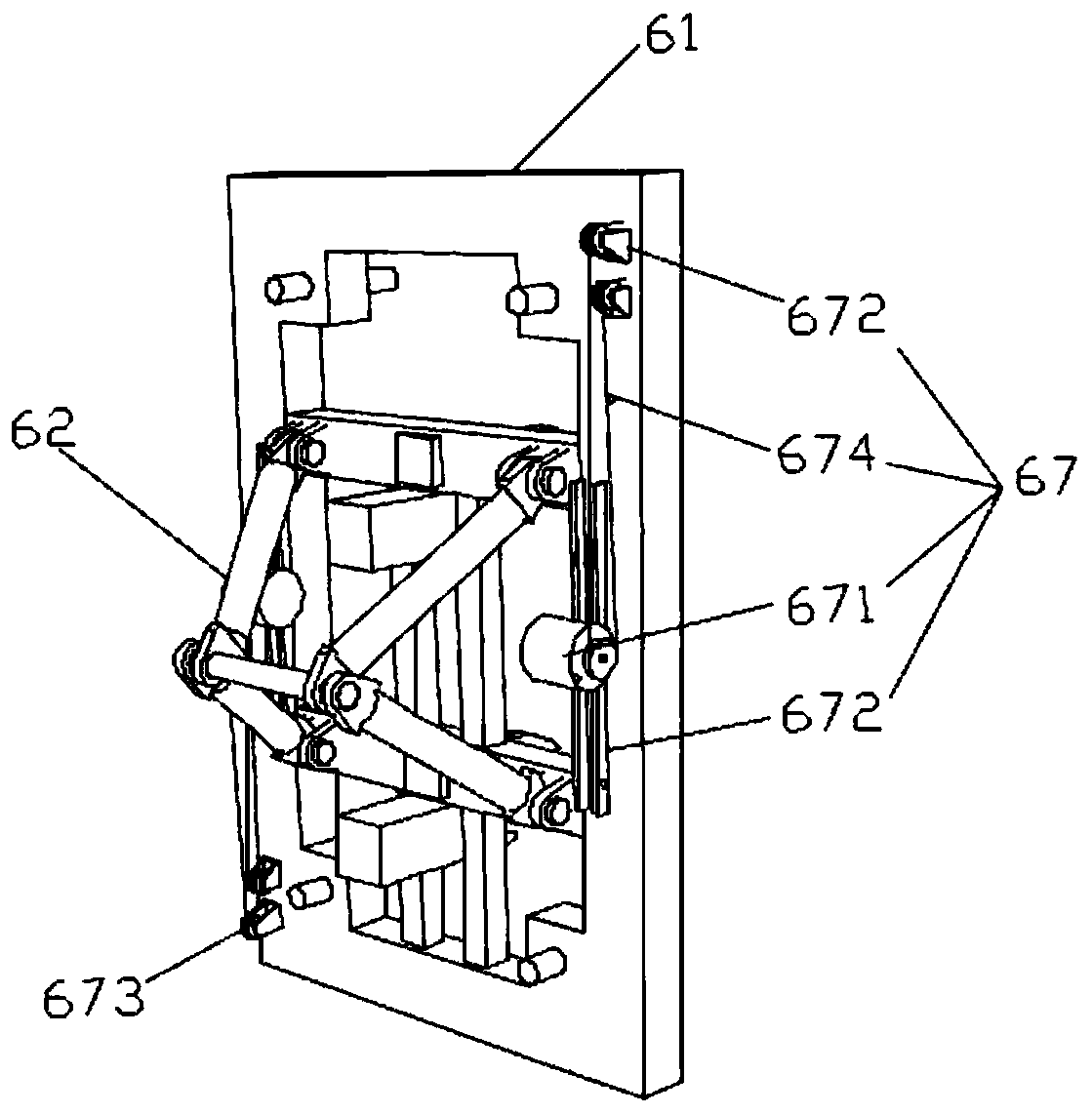

[0048] figure 1 Introduce the construction equipment integrating fixing, cutting and transportation of building components, which can remove building beams, slabs, shear walls and other building components. Specifically, the construction equipment includes a traveling device 1, a turning device 4 arranged above the traveling device 1, a mechanical arm 5 mounted on the rotating device 4, and a fixing device 6 in the present invention is arranged at the front end of the mechanical arm 5, The running device 1 is located on the working surface 7, which can be a floor board, and the fixing device 6 is used to dismantle the building components 8, figure 1 The middle building component 8 is a shear wall, and of course the building component can also be a beam-slab structure. The construction equipment may also include several legs 2, which may be connected to the frame of the traveling device 1 through the balance arm 3, and are used to support the construction equipment when the co...

Embodiment 2

[0060] This embodiment provides a construction method for quickly dismantling building components. The building component fixing, cutting, and transporting integrated construction equipment in Embodiment 1 is used to dismantle the building components. The following combines Embodiment 1 and the appended Figures 1 to 4 The removal method is further described, and the removal method specifically includes the following steps:

[0061] When the building components are fixed, cut and transported, the integrated construction equipment is walking in place, and the small hand-held drilling device is used to complete the cutting and leading holes on the building components, in preparation for the next step to penetrate the wire saw chain;

[0062] After adjusting the mechanical arm 5 so that the fixing device 6 is in place, the retractable fixing pin 63 is maintained in a retracted state, and the fixing device 6 is close to and parallel to the building component 8 to be removed by adju...

Embodiment 3

[0069] Because obstacles are often encountered on construction sites, the construction equipment integrating fixing, cutting, and transporting construction components provided in this embodiment has the function of overcoming obstacles, mainly by improving the walking device in the first embodiment. combine Figure 5 with Image 6 As shown, the traveling device includes a chassis 11 and a traveling mechanism 12 arranged on both sides of the chassis 11 . Described running mechanism 12 comprises first roller 13, second roller 14, adjustment flywheel 15, crawler belt 16, first elevator wheel system 17 and second elevator wheel system 18; Described first roller 13, first elevator wheel system 17 , the second lifting wheel system 18, and the second roller 14 are arranged on the chassis 11 in sequence; Turn and brake. combine Image 6 with Figure 7 As shown, the first lifting wheel system 17 and the second lifting wheel system 18 both include a box body 171, a lifting device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com