Cold plate inspection method

An inspection method and cold plate technology, which can be used in measuring devices, instruments, sorting and other directions, can solve the problems of high production cost, low efficiency, and cumbersome cold plate quality inspection process, so as to reduce the missed inspection rate and improve inspection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

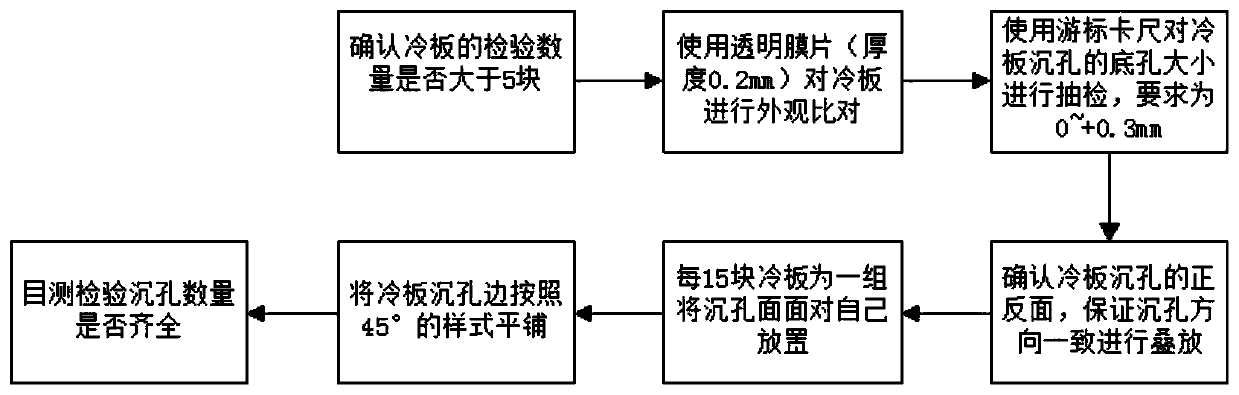

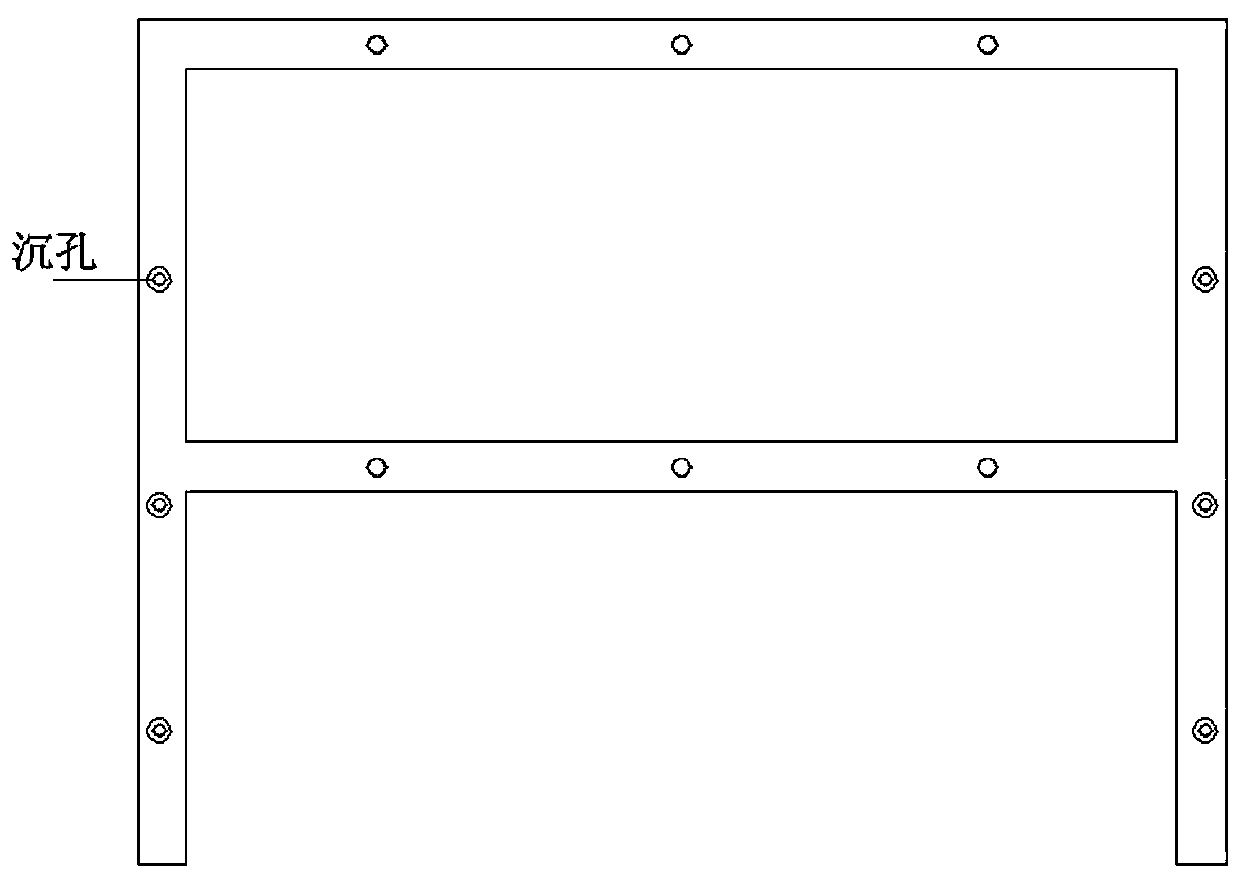

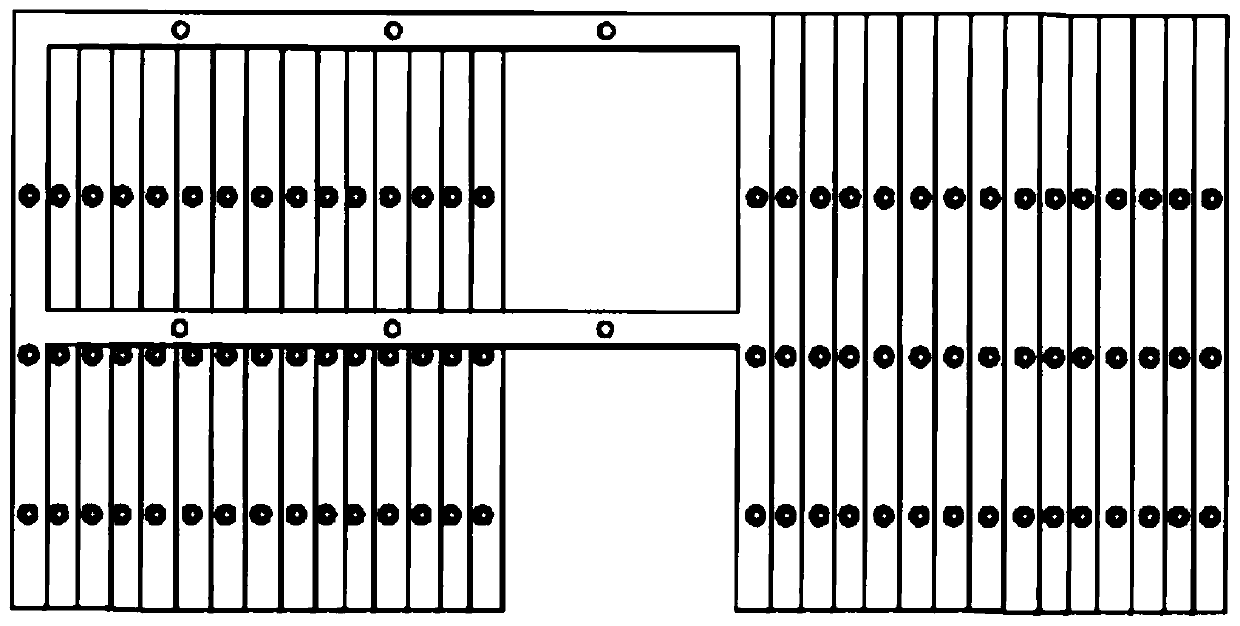

[0027] The invention provides a cold plate inspection method, which is suitable for the cold plate with the counterbore distributed at the edge of the cold plate, such as figure 1 As shown, including checking the appearance of the counterbore on the cold plate, checking the size of the bottom hole of the counterbore on the cold plate, and checking the number of counterbore holes on the cold plate, please refer to the structural diagram of the cold plate figure 2 .

[0028] Specifically, please continue to refer to figure 1 , when checking the appearance of the counterbore on the cold plate, first, observe with the naked eye whether the counterbore on each cold plate is a regular counterbore, that is, whether the size of the counterbore is consistent, and take out the cold plate with the counterbore of inconsistent size; secondly, use The transparent diaphragm is covered on the surface of the cold plate, and the position and size of the counterbore on the cold plate are inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com