Intelligent manufacturing laboratory management system

A management system and intelligent manufacturing technology, applied in the field of information management, can solve the problems of production information lag, failure to display, time-consuming and labor-intensive follow-up response, etc., and achieve the effect of realizing intelligent management, improving the degree of automation, and improving production tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

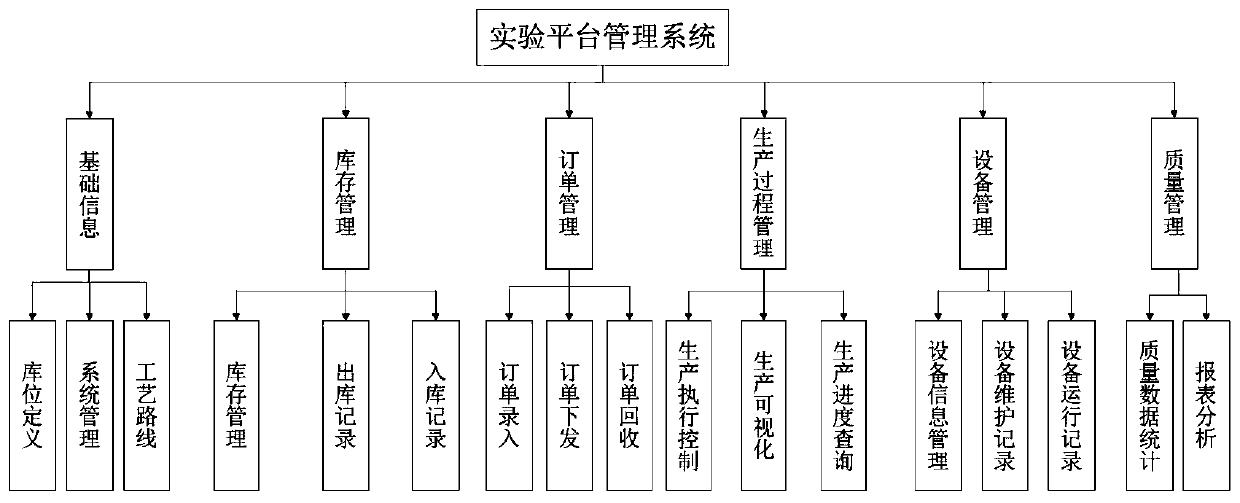

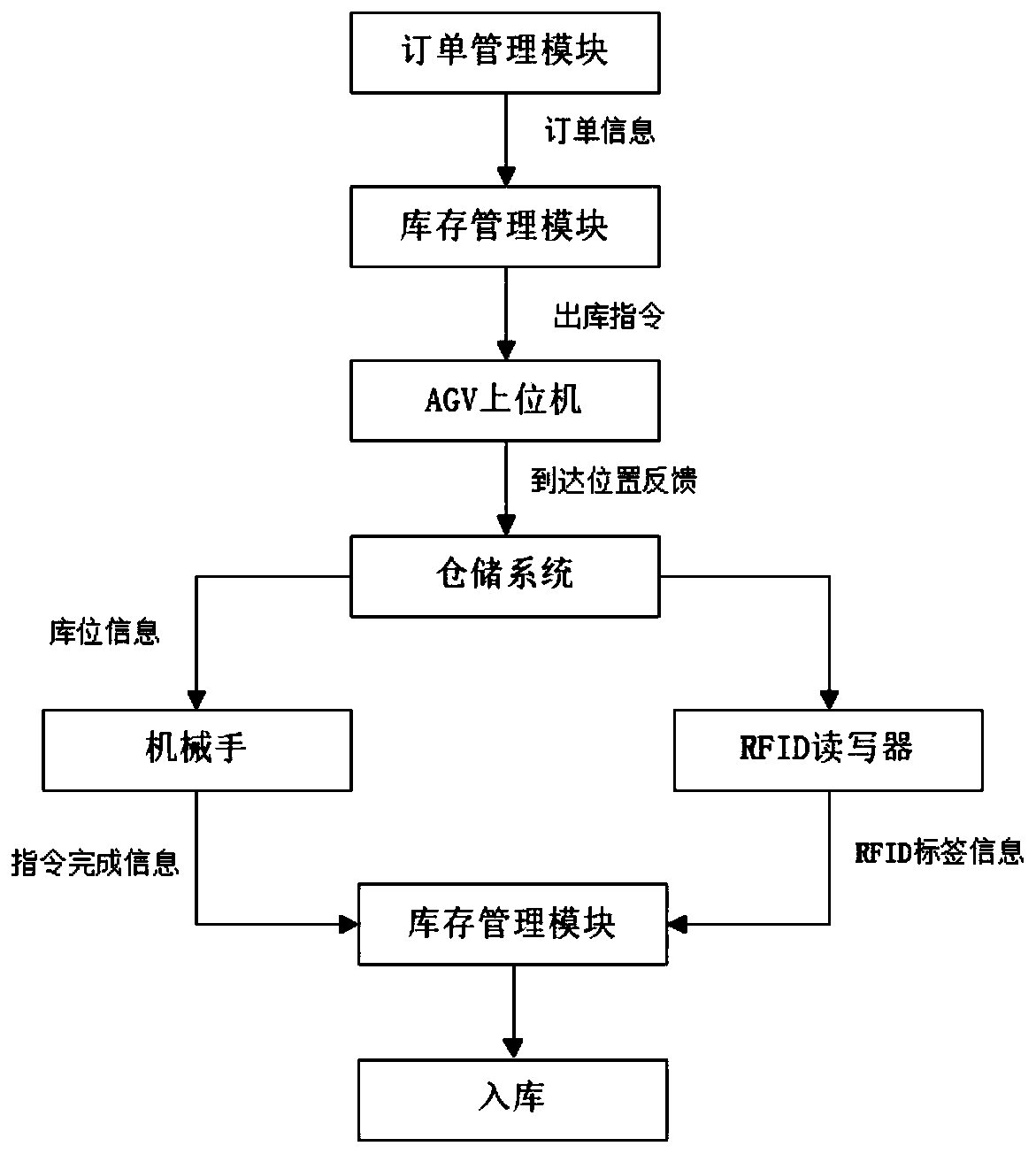

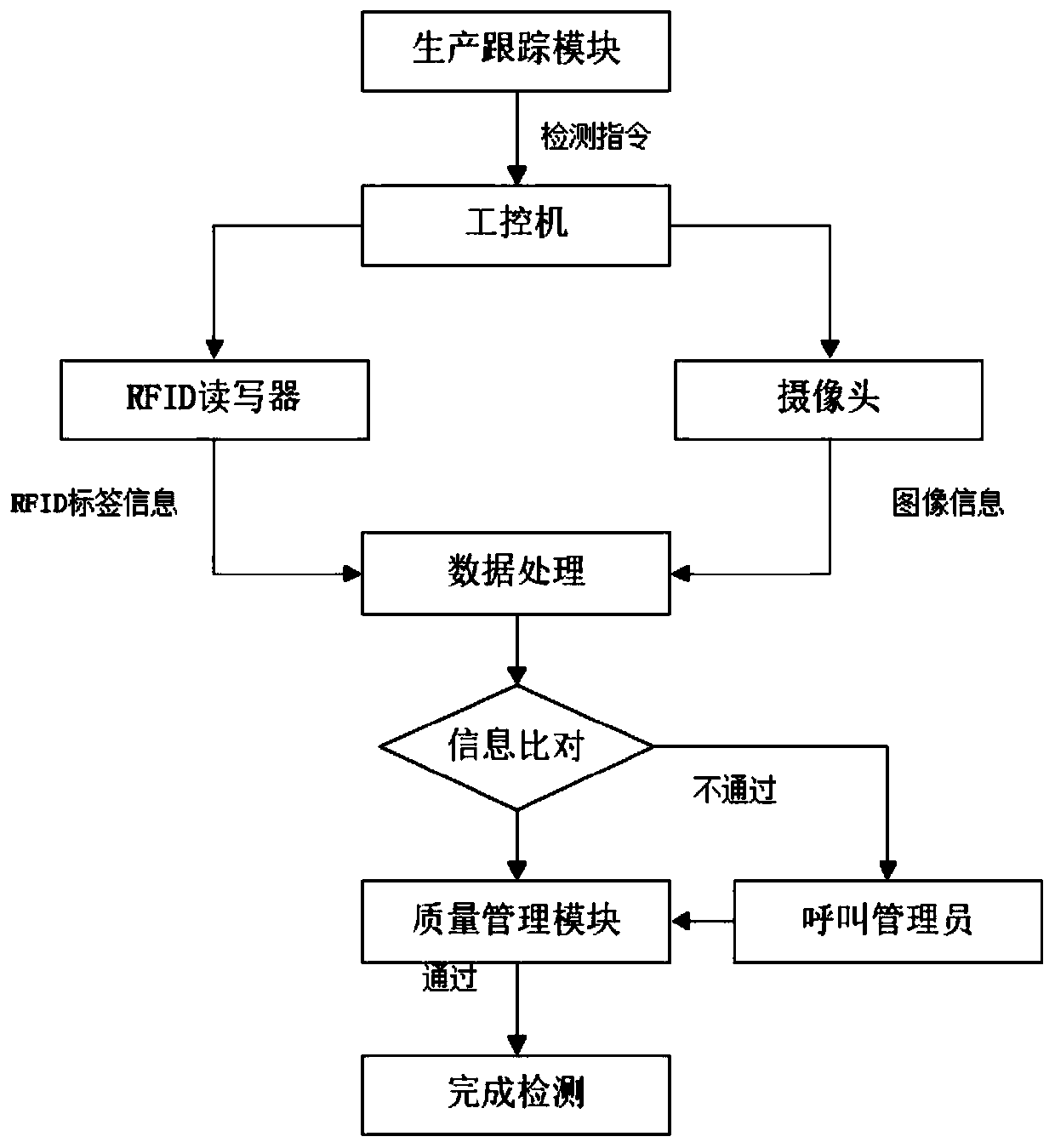

[0017] like figure 1 , an intelligent manufacturing laboratory management system, comprising a basic data management module, an inventory management module, an order management module, a production process management module, an equipment management module, and a quality management module, wherein the basic data management module includes user management, warehouse location Definition, formulation of production process routes, and inventory warning quantity setting; the inventory management module is used to perform storage and inventory warning operations according to the product and raw material storage and storage plan, and record material storage and storage information, and update inventory; the order management module It is used to implement production order management, including order information entry, order issuance, generation of outbound preparation orders, and order recovery; the production process management module is used to track the production process, including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com