Carbon fiber composite material rod joint

A composite material and rod joint technology, which is applied in the field of carbon fiber composite material rod joints, can solve problems such as lack of glue, affecting the connection strength of joints and composite material rods, and pressure applied by the glue layer, so as to achieve small assembly stress and high overall structural stability , the effect of uniform glue layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

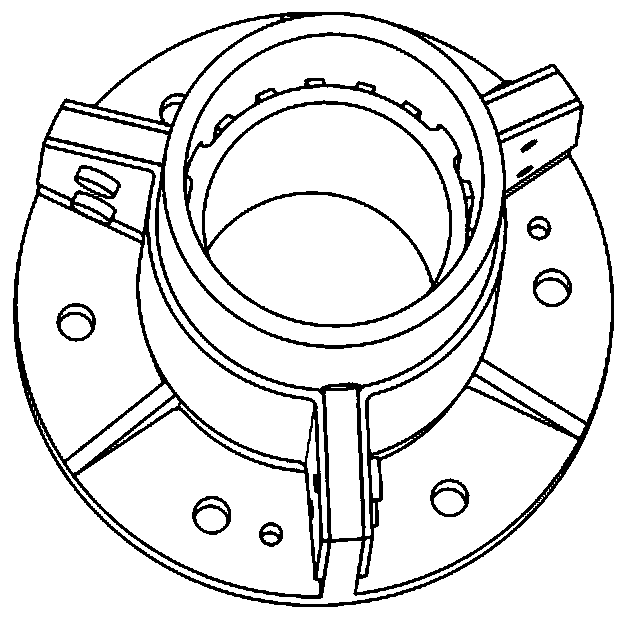

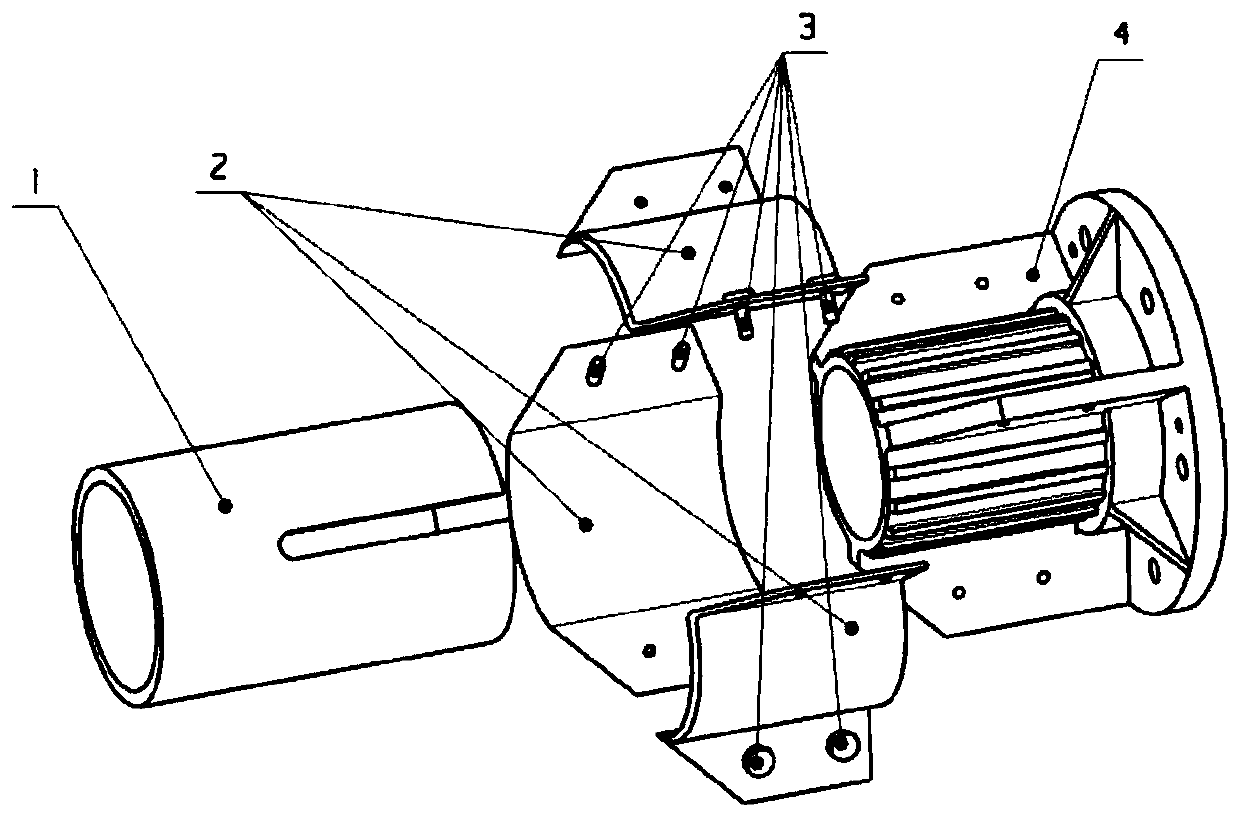

[0037] refer to Figure 1-7 , a carbon fiber composite material rod 1 joint, including a base 4, a force transmission tile 2, the base 4 includes a flange 4-1, a central cylinder 4-4 arranged on the flange 4-1, and a central cylinder symmetrically arranged 4-4 three radial partitions 4-3 of the outer wall,

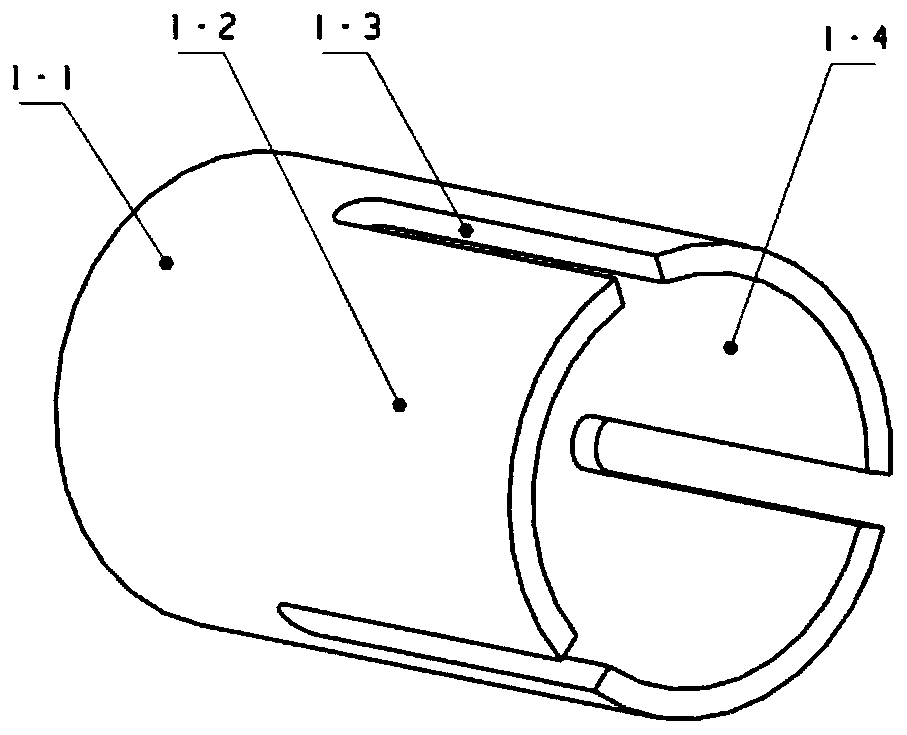

[0038] The composite material rod 1 is provided with three slots 1-3 that fit in clearance with the partition plate 4-3, and the three slots 1-3 are symmetrically distributed at 120° around the axis of the composite material rod 1, and the composite material rod 1 is The outer surface of the remaining part of the rod segment 1-1 cut by the groove 1-3 is the rod bonding area 1-2. The slot 1-3 of the composite material rod 1 passes through the partition plate 4-3, so that the positioning inner wall 1-4 of the composite material rod 1 is clearance-fitted with the outer wall of the central cylinder 4-4.

[0039] The force transmission tile 2 is a thin-walled structure, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com