Automatic gear shifting mechanism of transmission

An automatic shifting and transmission technology, applied in mechanical equipment, transmission control, components with teeth, etc., can solve the problems of low transmission efficiency, asynchronous acceleration, environmental pollution of hydraulic oil, etc., and achieve high shifting stability. , The device has the advantages of simple structure and high shifting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

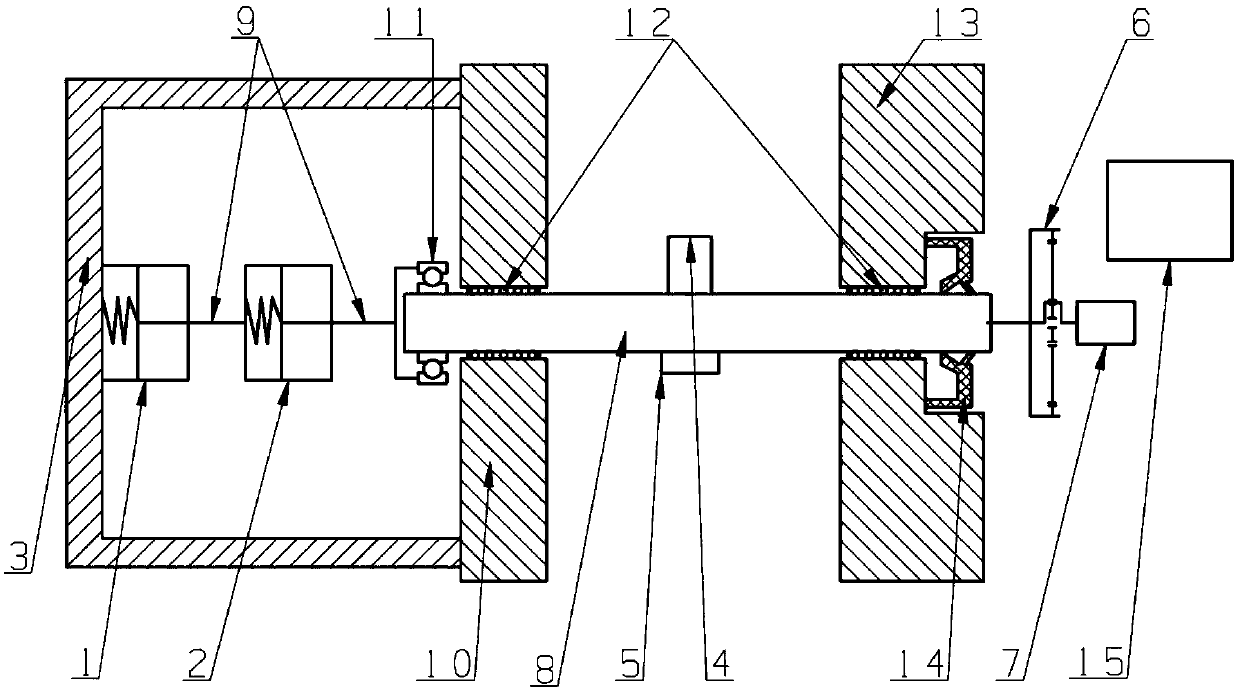

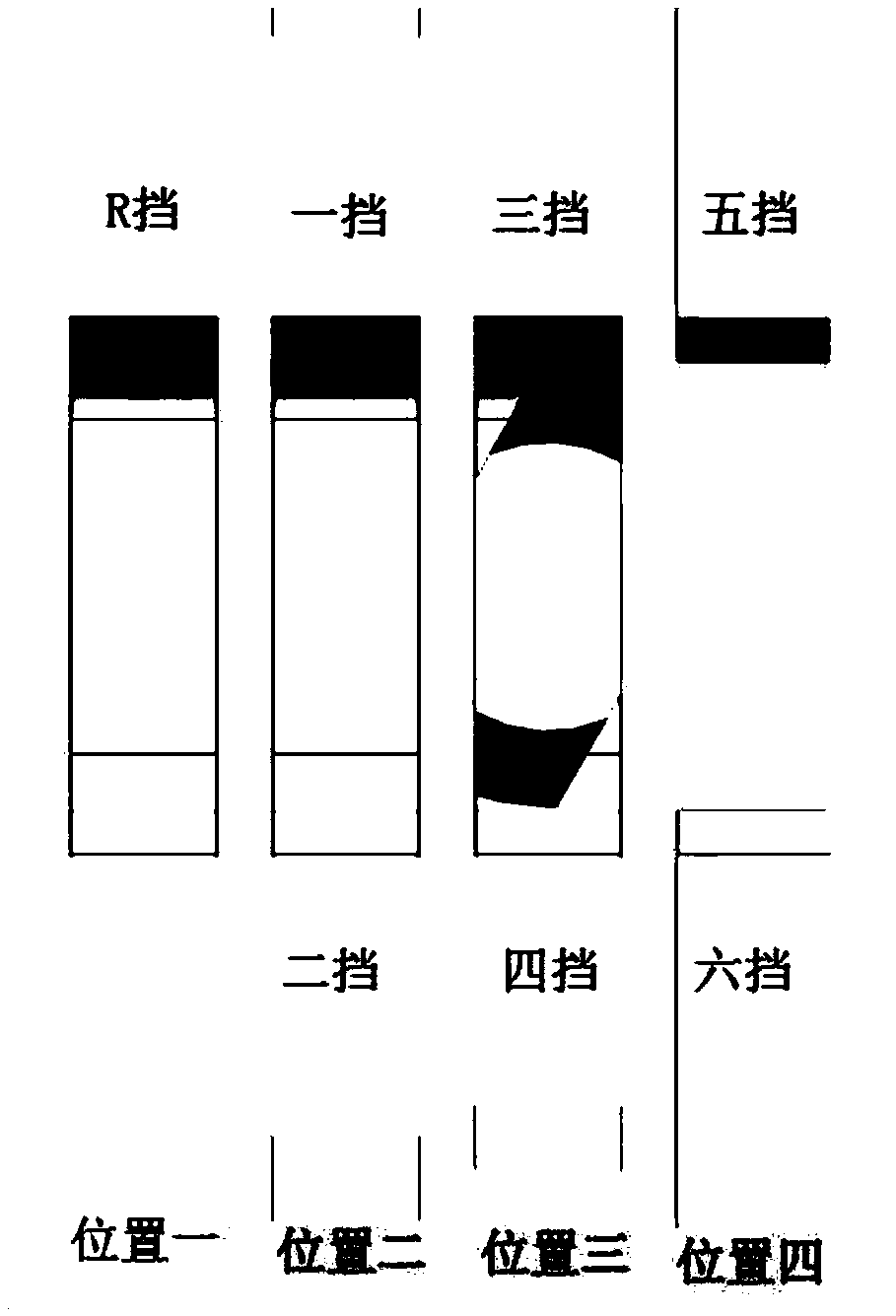

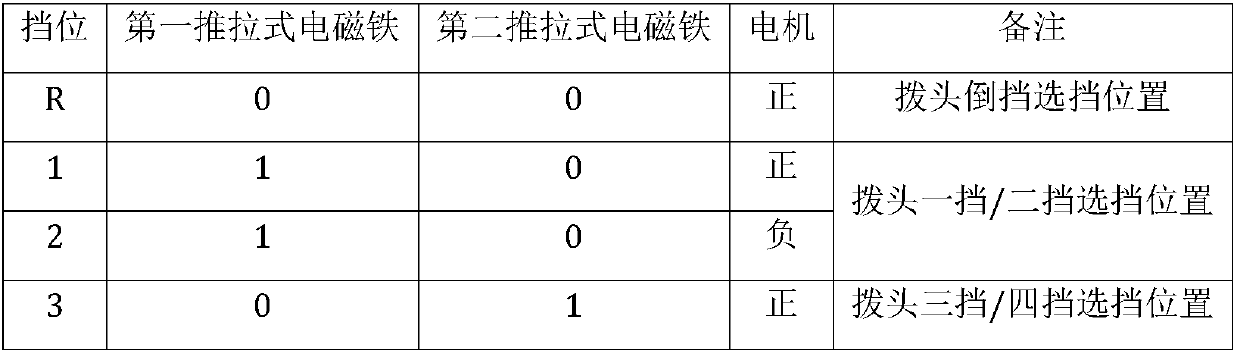

[0021] Such as figure 1 As shown, it is an automatic shifting mechanism of a transmission involved in this embodiment, including: a control cover 3, a first middle plate 10, a second middle plate 13, a coaxially arranged first push-pull electromagnet 1, a second push-pull Type electromagnet 2, have the gear selection mechanism for detecting the position sensor 5 of push-pull type electromagnet, operating mechanism and the controller 15 that are connected with it respectively, wherein: the detection signal judgment of controller 15 acquisition position sensor 5 produces four A gear selection position and whether the gear selection is in place, and send an instruction to the shift motor 7 to realize gear shifting.

[0022] The shell of the first push-pull electromagnet 1 is fixedly connected with the control cover 3 , and the shell of the second push-pull electromagnet 2 is fixedly connected with the push rod 9 of the first push-pull electromagnet 1 .

[0023] A ball bearing 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com