Multi-flow tandem type plate heat exchanger

A plate heat exchanger and series technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problem of low heat exchange efficiency, reduce power consumption, ensure uniformity, high resistance The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

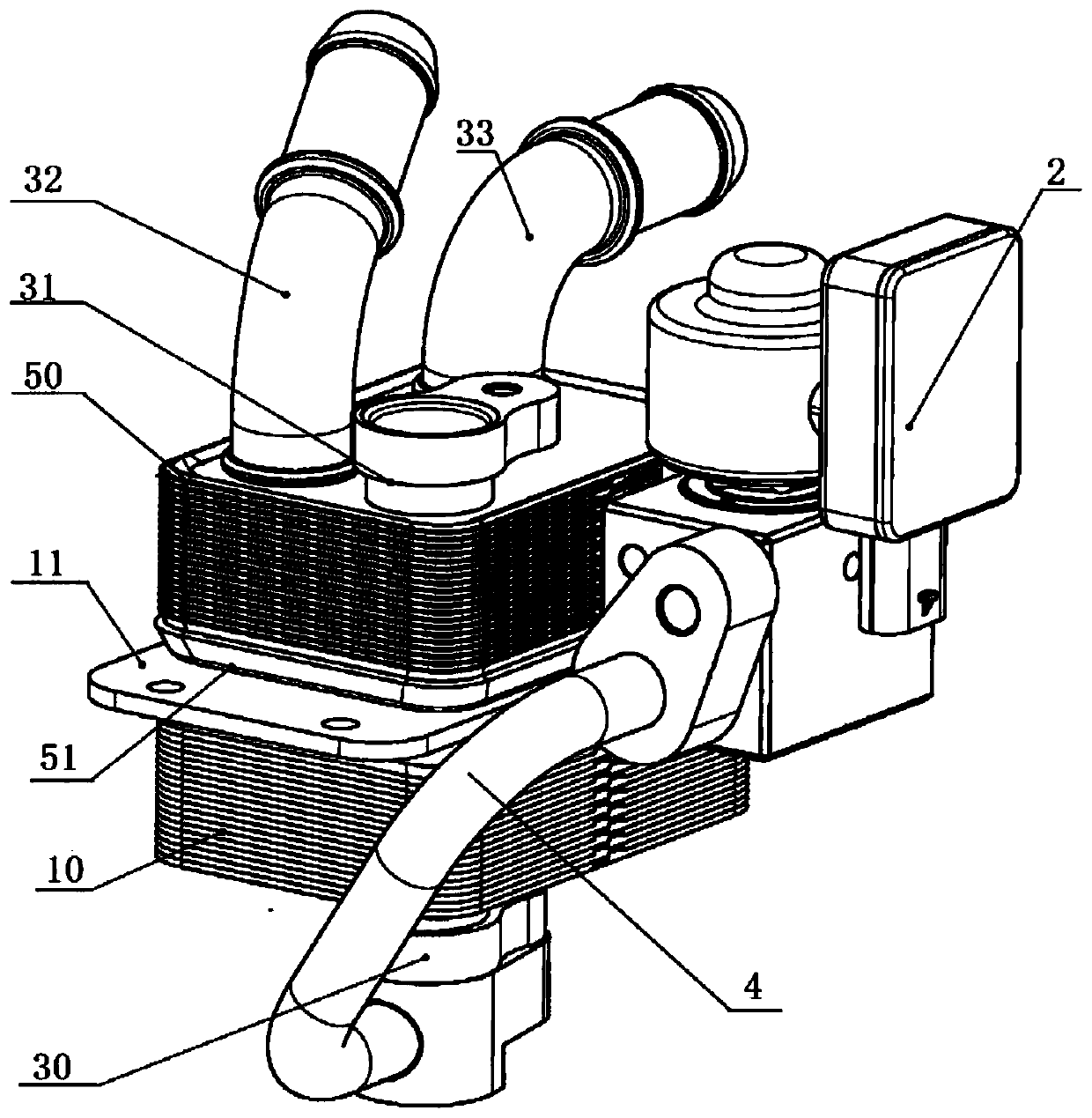

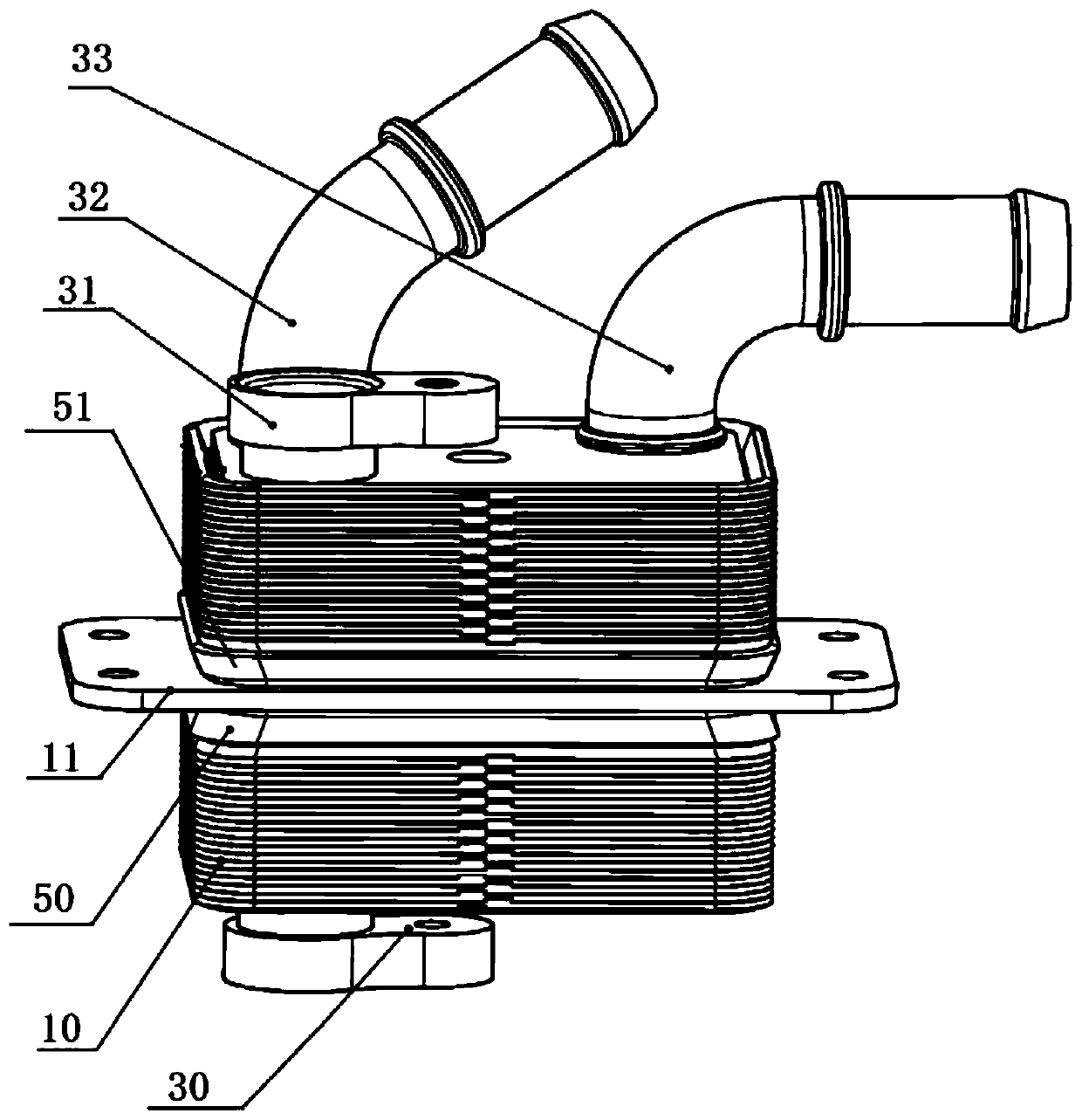

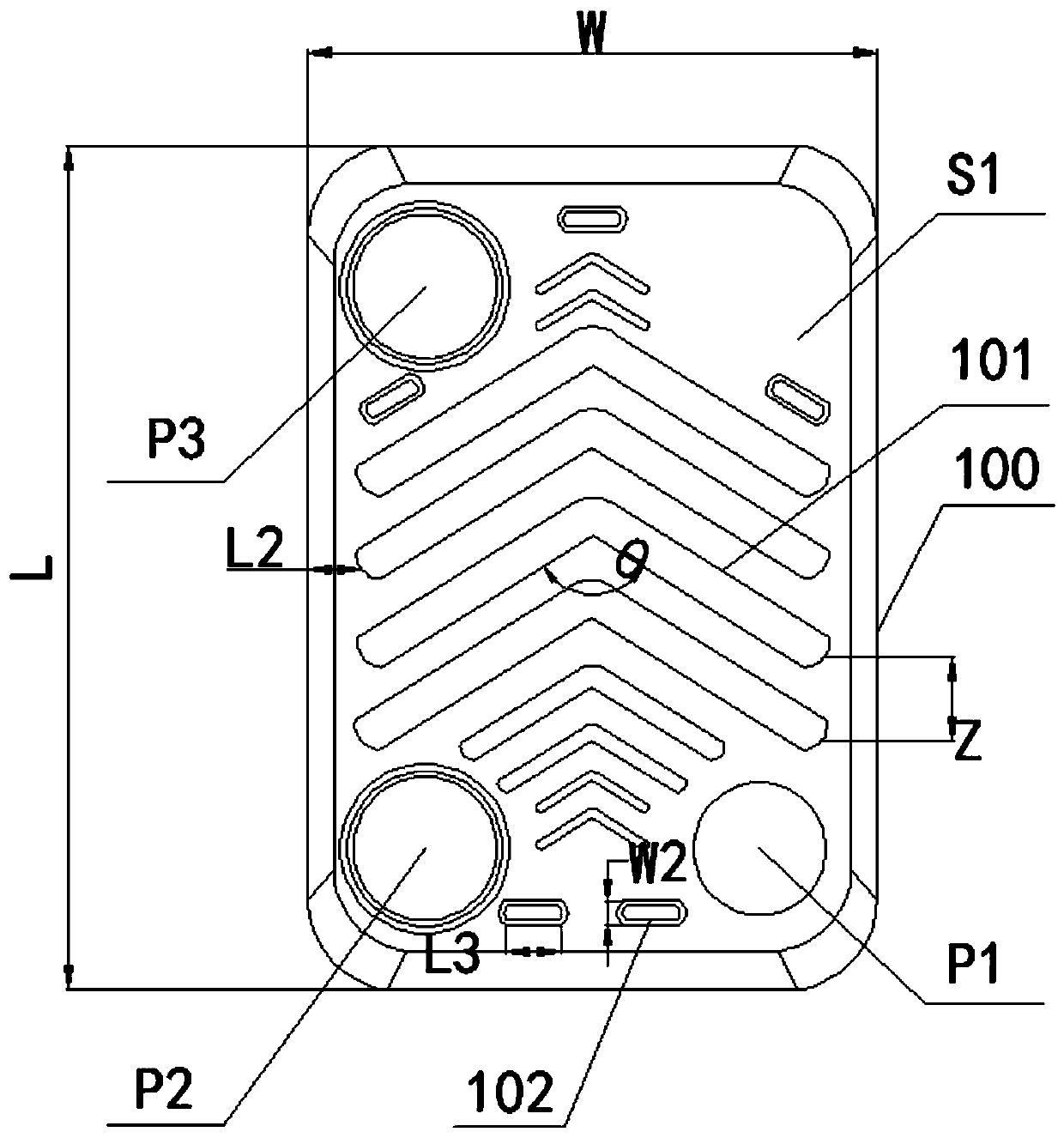

[0033] Such as Figure 1-9 As shown, an embodiment of the present invention discloses a multi-flow series plate heat exchanger, including a heat exchanger body and an electronic expansion valve 2, a refrigerant inlet and a refrigerant outlet are arranged on the refrigerant side of the heat exchanger body, and the refrigerant inlet is provided with There is a refrigerant inlet pressure plate 30, and the refrigerant outlet is provided with a refrigerant outlet pressure plate 31; a water inlet and a water outlet are provided on the refrigerant side of the main body of the heat exchanger, and the water inlet is connected to a water inlet pipe 32, and the water outlet is connected to a water outlet pipe 33; the electronic expansion valve 2 The pipe 4 communicates with the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com