High-precision FBG high-temperature sensor and working and manufacturing method thereof

A high-temperature sensor, high-precision technology, applied in the direction of instruments, thermometers, scientific instruments, etc., can solve the problems of sensor function and size, low reliability, low sensitivity, etc., to achieve the elimination of wavelength nonlinear drift and high temperature measurement accuracy , the effect of high reflected light power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

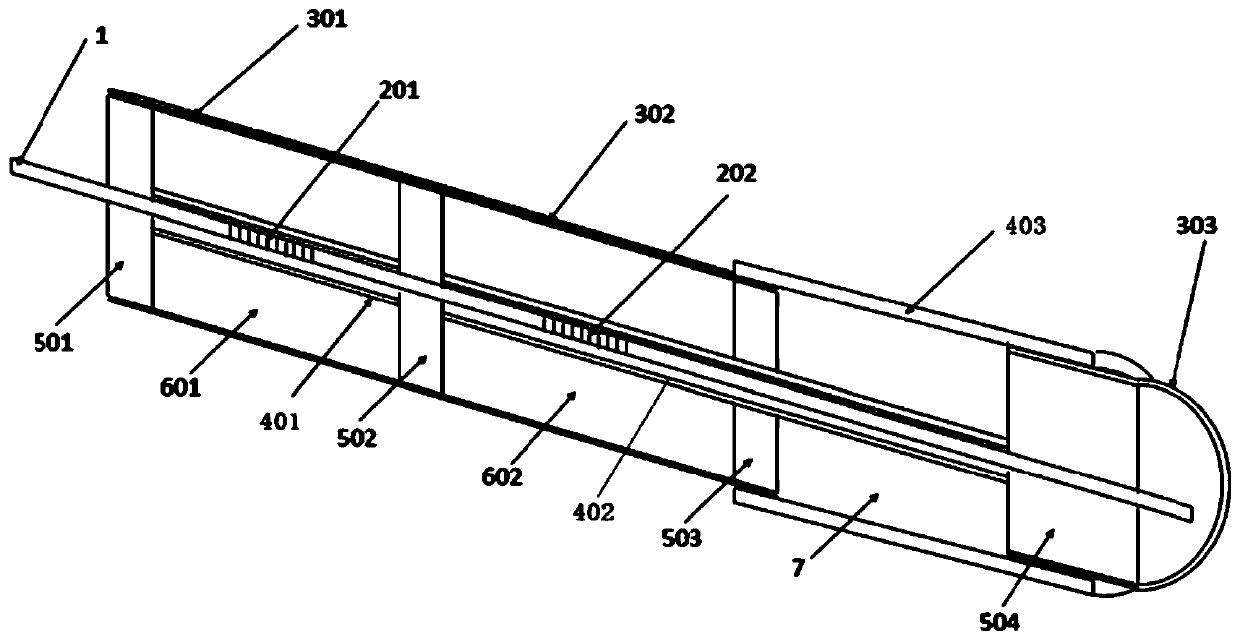

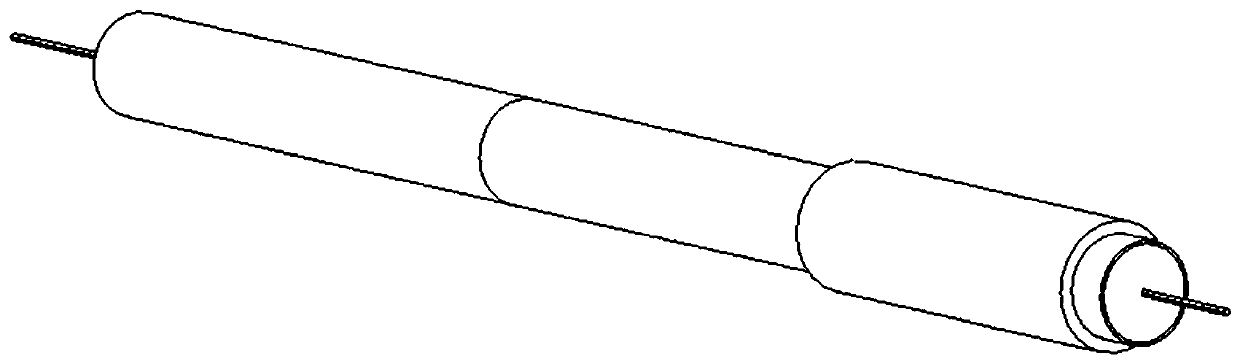

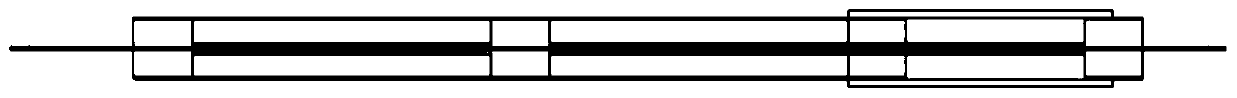

[0087] Such as figure 1, a high-precision FBG high-temperature sensor, the sensor includes a bare optical fiber 2, a long packaging casing casing (301, 302), a third packaging casing casing 303, a first thermal insulation casing 401, a second thermal insulation casing 402, a High-temperature epoxy resin anchoring end 5, annular thermal insulation area 6, silicone rubber. The optical fiber passes through the second thermal insulation sleeve 402, and the outside of the position where the grating is located is filled with an annular thermal insulation area 6, and outside the annular thermal insulation area is an encapsulation casing sleeve (301, 302).

[0088] One end of the temperature measuring FBG202 and one end of the temperature compensation FBG201 are anchored together, and the other end is anchored to the movable packaging casing sleeve 303 through the second thermal insulation sleeve 402 through the silicon rubber temperature sensing area.

[0089] The temperature sensin...

Embodiment 2

[0092] A manufacturing method of a high-precision FBG high-temperature sensor includes fixing the FBG in a tube furnace, closing the tube furnace, inserting high-temperature cotton at both ends, and completing the annealing process.

Embodiment 3

[0094] Embodiment 2 is repeated, except that the temperature measurement area and the temperature compensation area are connected by high temperature resistant epoxy resin, and spot welding can also be used to connect the first packaging casing sleeve 301 and the second packaging casing sleeve 302 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com