Object material classification method for pulse type ToF depth camera

A depth camera and pulse-type technology, which is applied to computer components, instruments, character and pattern recognition, etc., can solve problems such as low accuracy and affecting classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings.

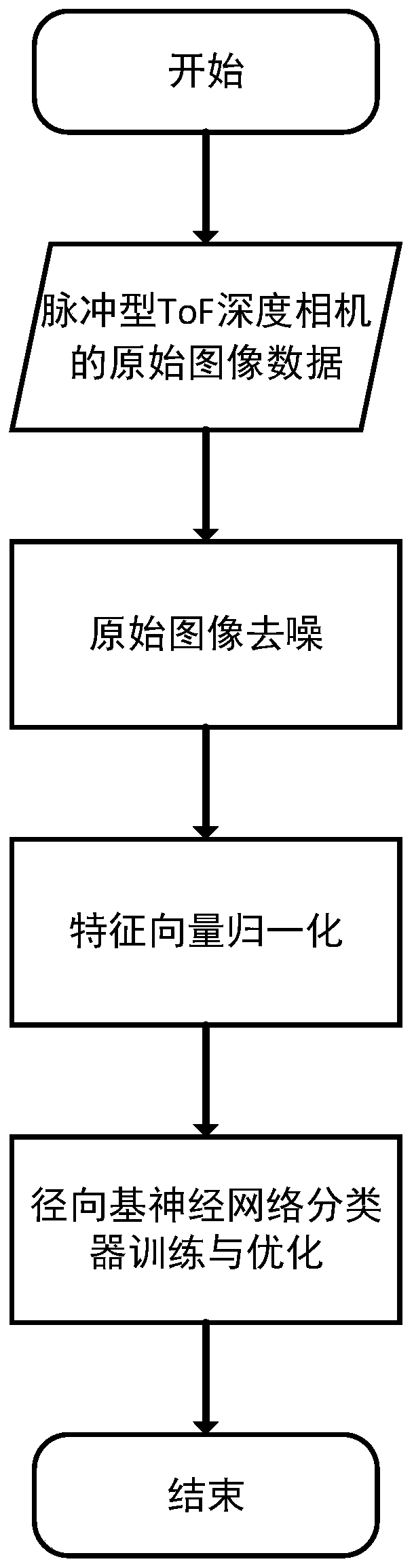

[0046] figure 1 It is an overall flow chart of a method for object material classification suitable for pulse-type ToF depth cameras proposed by the present invention, such as figure 1 shown, including:

[0047] Original ToF image denoising module, feature vector normalization module, radial basis neural network classifier training and optimization module.

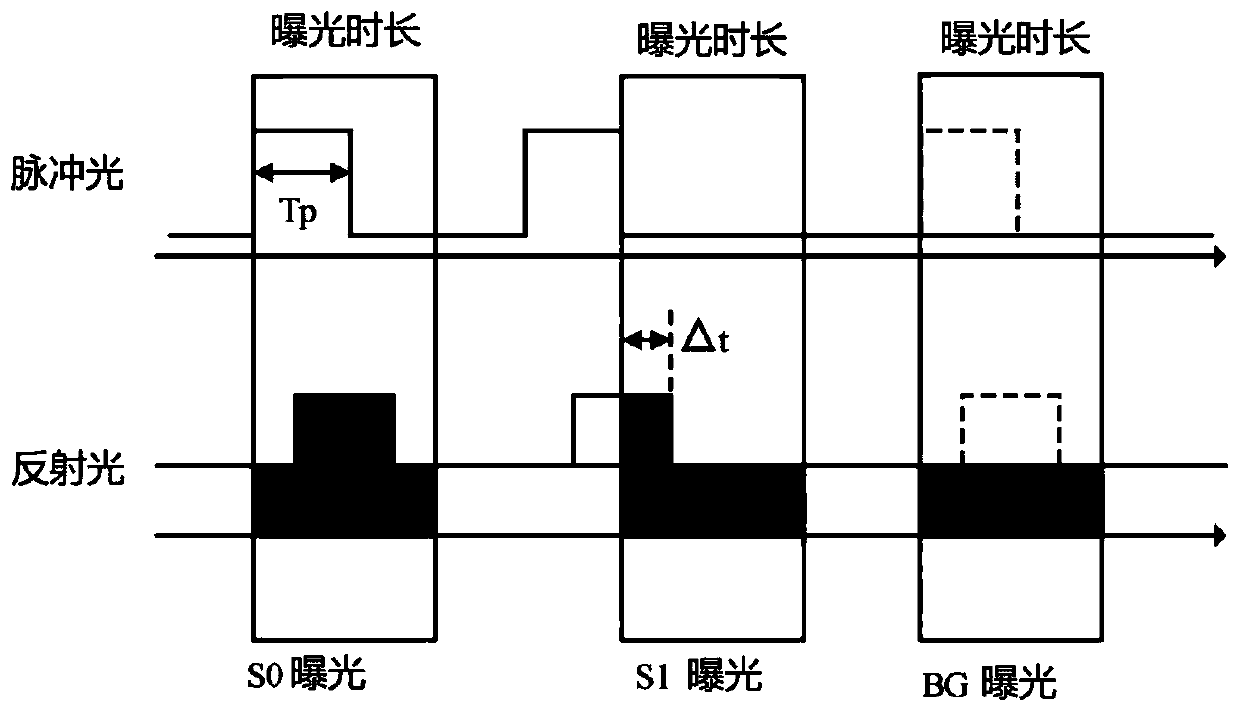

[0048] The parameters of the pulse-type ToF depth camera in the implementation: the pulse width is T p =44ns, can measure the depth map between 0.5-6.6m

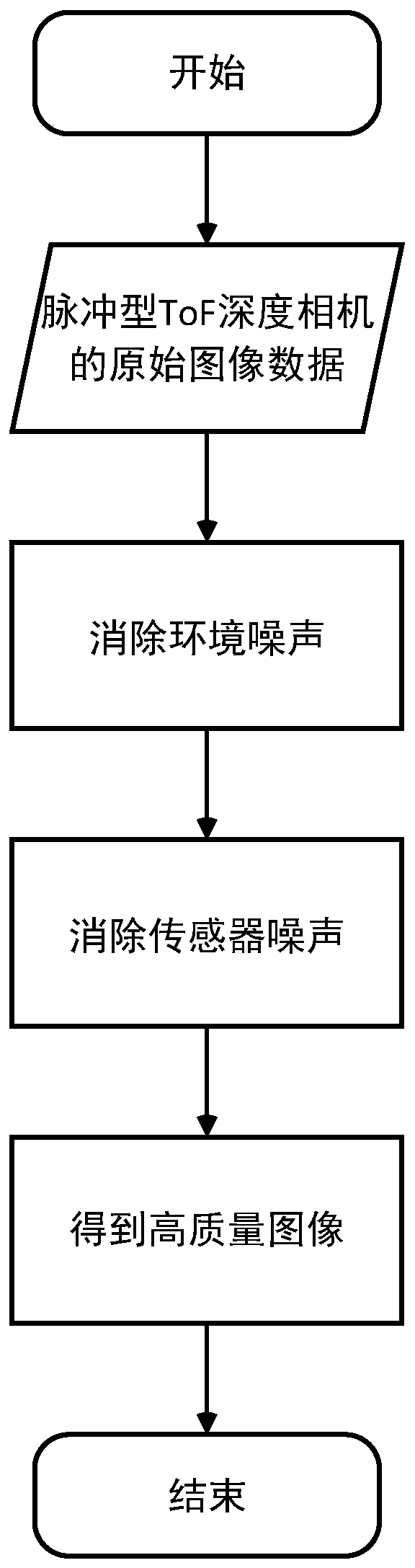

[0049] Original ToF image denoising module: the method of eliminating environmental noise, controlling the pulse-type ToF depth camera to collect a picture with an exposure time of T without emitting infrared pulses p The ambient noise image BG. use image 3 The infrared image exposed by S0 and the infrared image exposed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com