Bus power transmission system and bus pipeline supporting device thereof

A technology for bus ducts and supporting devices, which is applied in the direction of fully enclosed bus devices, bus installation, switchgear, etc., can solve the problems of easy damage stability of bus ducts, easy damage of bus ducts, etc. The effect of stress damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

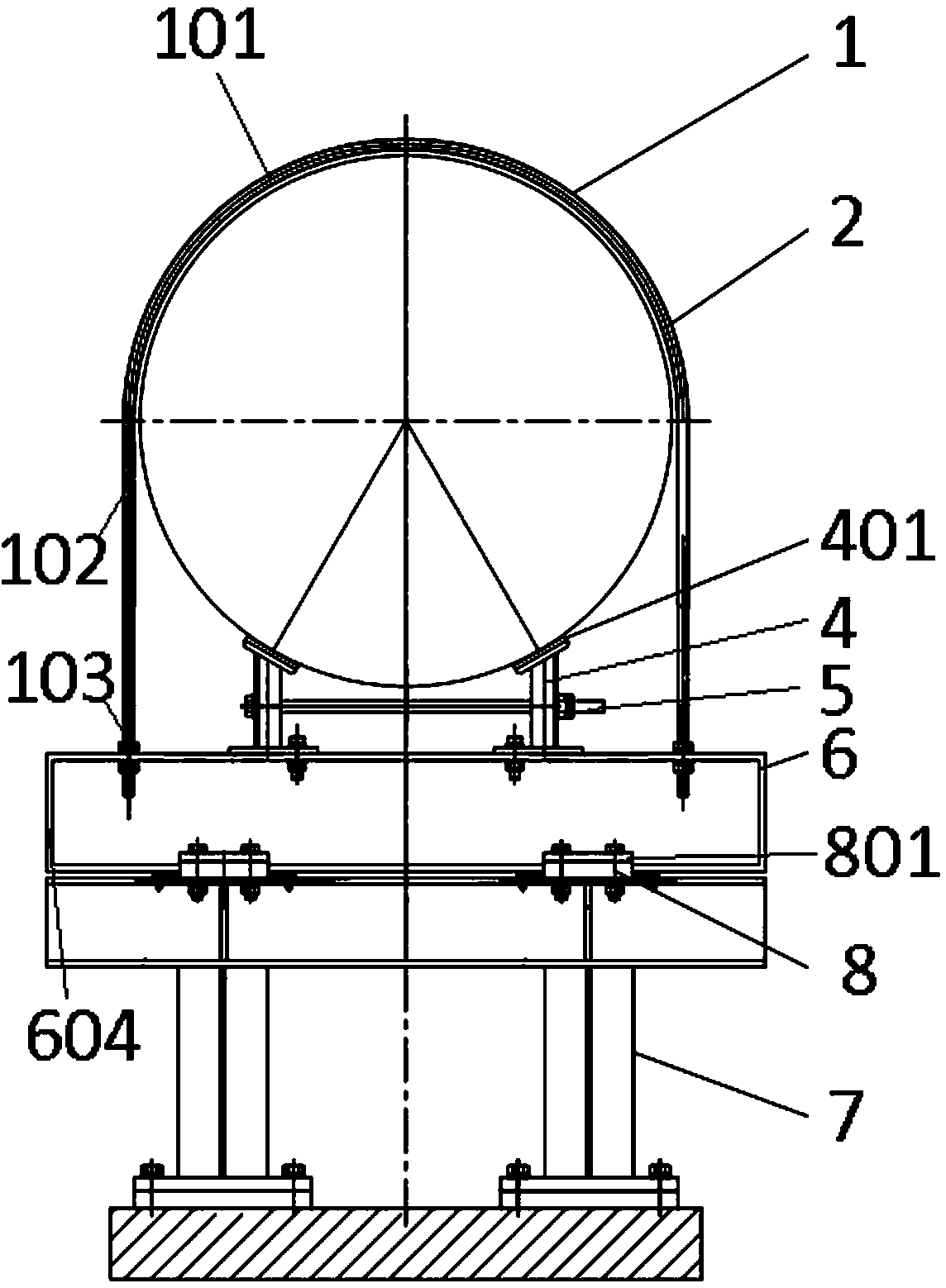

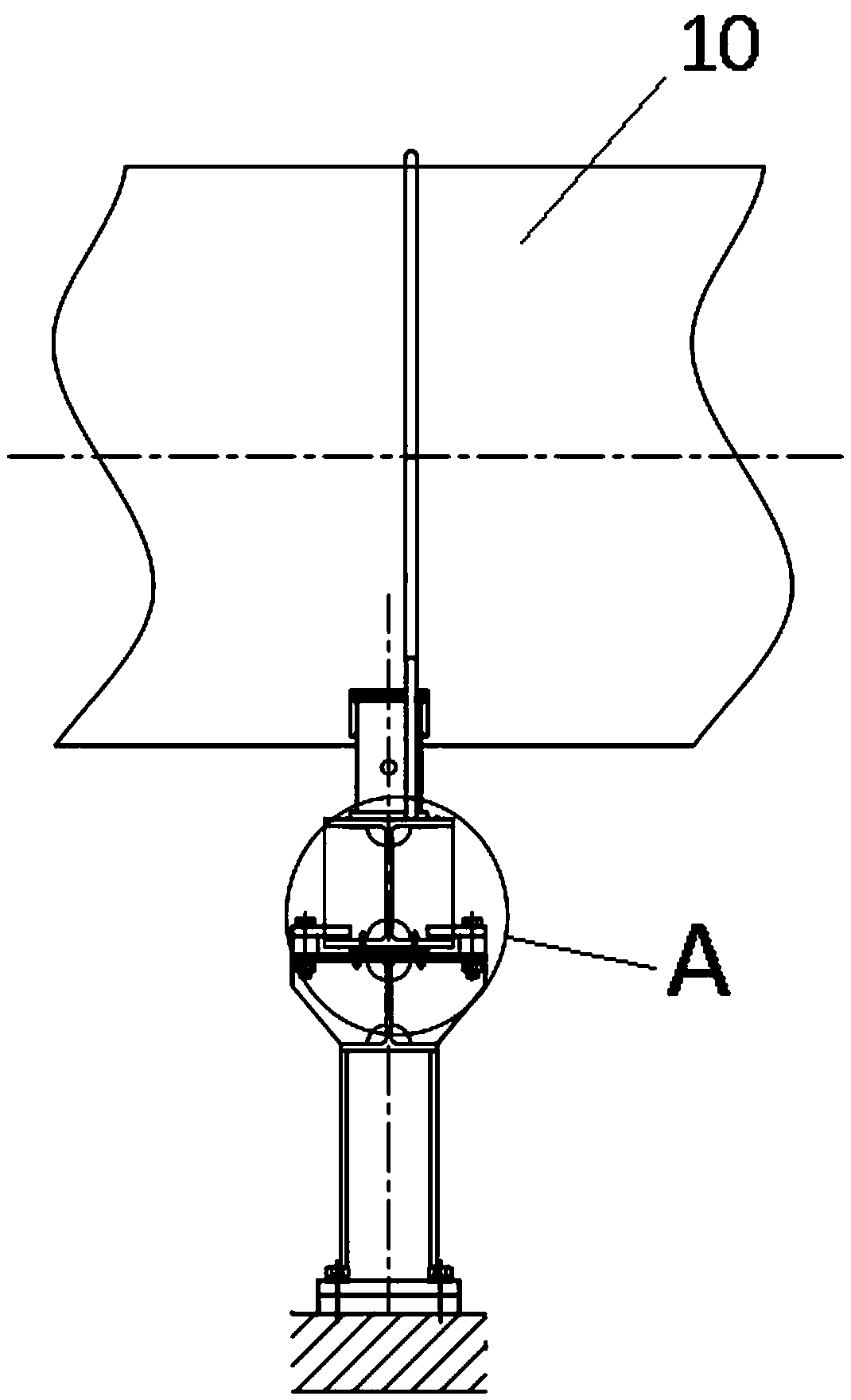

[0052] Specific embodiment 2 of the busbar power transmission system of the present invention. In this embodiment, the structure of the busbar power transmission system is simplified. In this embodiment, the busbar power transmission system includes a busbar duct and a busbar duct supporting device supporting the busbar duct. The busbar duct supporting device It includes a support seat for supporting the bus duct, on which a bus assembly structure is provided, and the bus assembly structure has a structure for the bus duct to pass through for sliding fit with the bus duct along the axial direction of the bus duct and along the radial direction of the bus duct. The busbar slideway that fits in the direction of the busbar duct. By setting the busbar assembly structure, the busbar duct can slide along the axis of the busbar duct when thermal displacement occurs, so as to avoid damage to the busbar duct and the supporting seat.

[0053] Specific embodiment 3 of the busbar power tr...

specific Embodiment 9

[0059] Embodiment 9 of the bus power transmission system of the present invention, as a further optimization of any one of Embodiments 2 to 7, the bus assembly structure further includes a buffer structure arranged between the bus duct and the bus slideway. Certainly, no buffer structure may be provided in other embodiments.

[0060] The specific embodiment 10 of the bus power transmission system of the present invention, as a further optimization of the specific embodiment 9, the buffer structure is a heat-shrinkable sheath arranged between the bus duct and the bus slideway. Certainly, in other embodiments, the buffer structure may also be a rubber pad provided on the bus bar clamp.

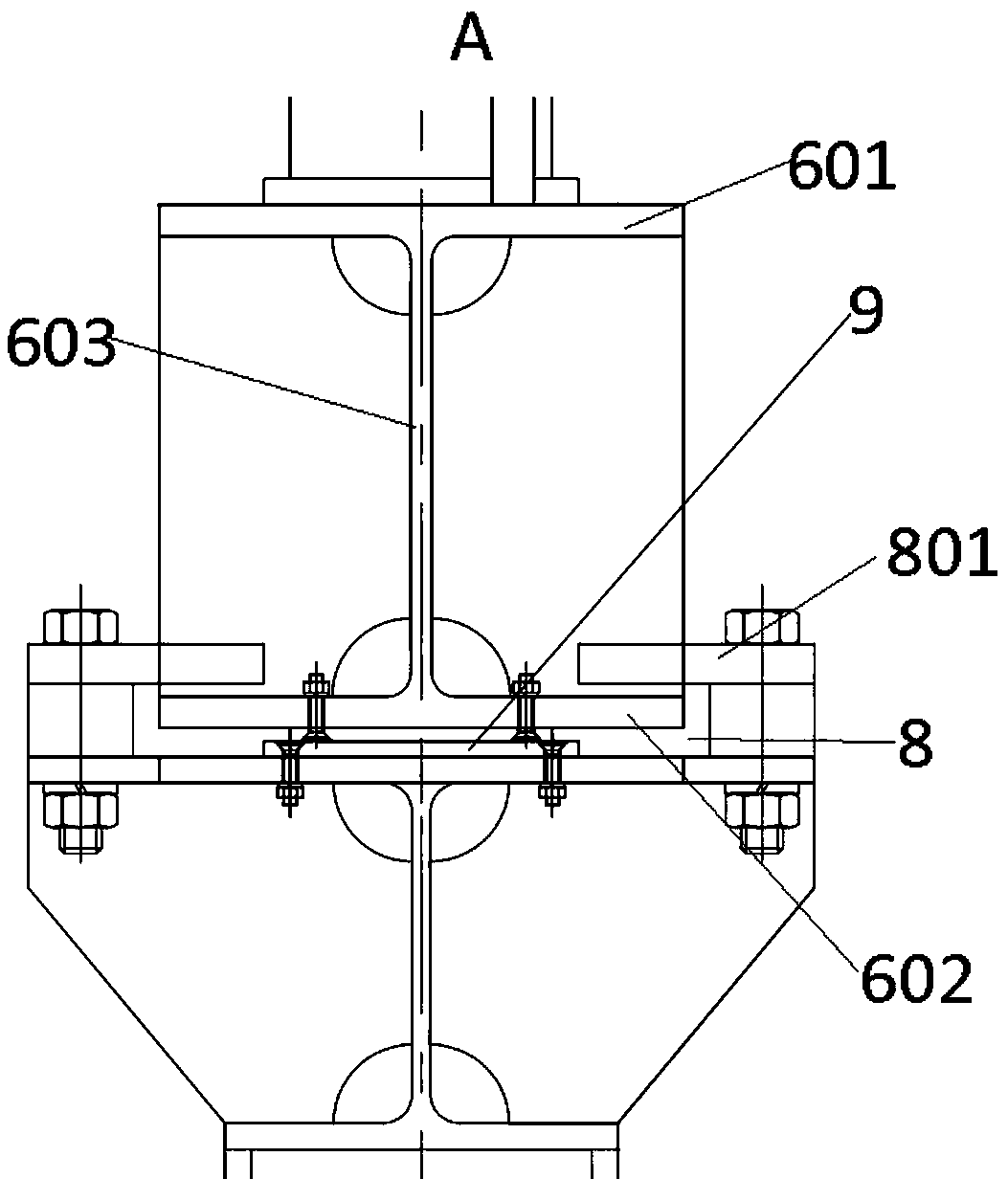

[0061] The specific embodiment 11 of the busbar power transmission system of the present invention, as a further optimization of any one of the specific embodiments 2 or 3, the support seat includes a seat body and a sliding seat slidingly assembled on the seat body, and the busbar assembly stru...

specific Embodiment 20

[0070] The specific embodiment 20 of the bus power transmission system of the present invention differs from the specific embodiment 1 of the bus power transmission system of the present invention only in that the supporting seat is an integrated tubular structure.

[0071] The specific embodiment 21 of the bus power transmission system of the present invention differs from the specific embodiment 1 of the bus power transmission system of the present invention only in that the slider is cylindrical and extends towards the radial direction of the bus duct, and the slide rail is cylindrical The sliding block is matched with the cylindrical sliding rail, and the two side walls of the notch of the cylindrical sliding rail are slidably matched with the web.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com