Magnetic auxiliary laser patterning Micro-LED mass transfer method

An auxiliary laser and transfer method technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of long transfer cycle, low product reliability, and damage to Micro-LED chips, so as to achieve high applicability and avoid transfer failure Control and avoid the effect of mura

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

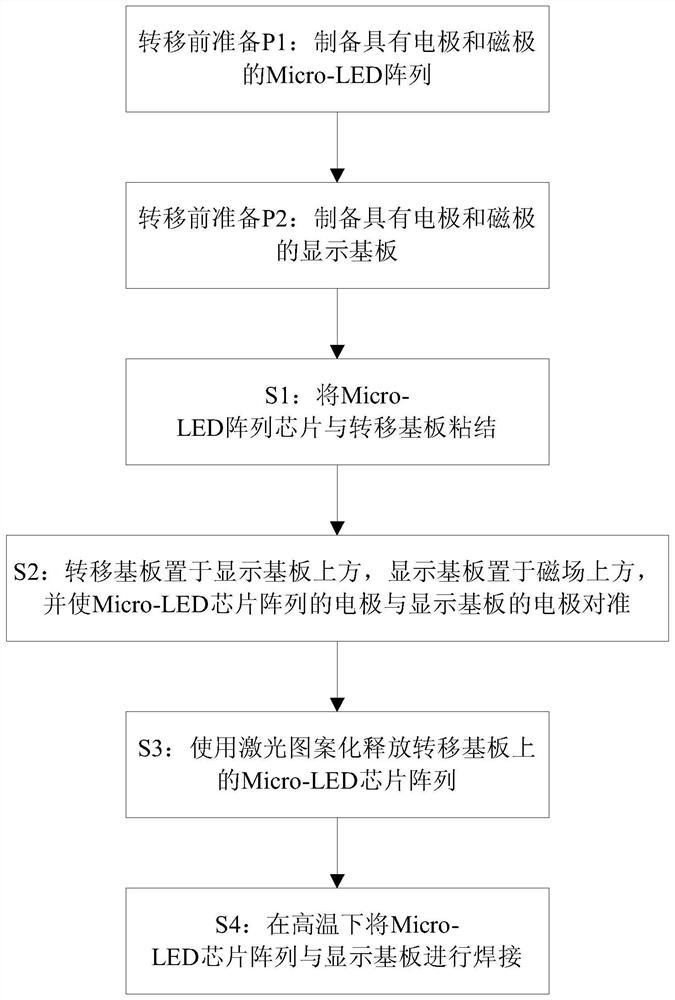

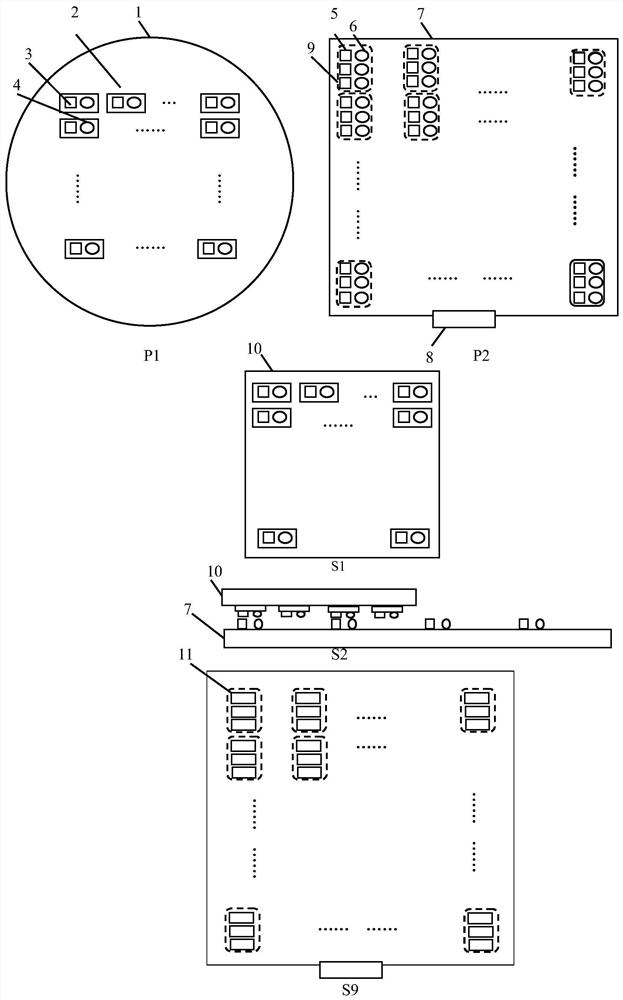

[0028] The present invention designs a magnetically assisted laser patterned Micro-LED mass transfer method, which prepares the transfer substrate of the Micro-LED array with electrodes and magnetic poles and prepares the display panel with corresponding electrodes and magnetic poles, and releases the glue by heating the laser The layer reduces the adhesive force of the adhesive layer, and the transfer of the Micro-LED array to the display substrate is realized with the assistance of the magnetic force at the corresponding position. The subsequent interconnection between the Micro-LED array and the display substrate is realized by heating, pressing, etc., which can be efficiently and accurately Transfer Micro-LEDs. The basic steps are as figure 1 shown.

[0029] Preparation before transfer P1: Prepare the Micro-LED array with electrodes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com