High-voltage accelerating tube

An accelerator tube, high voltage technology, applied in the direction of DC voltage accelerator, electrical components, accelerators, etc., can solve the problems of affecting product use, low voltage resistance, high leakage rate, avoiding stress damage and low vacuum leakage rate , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

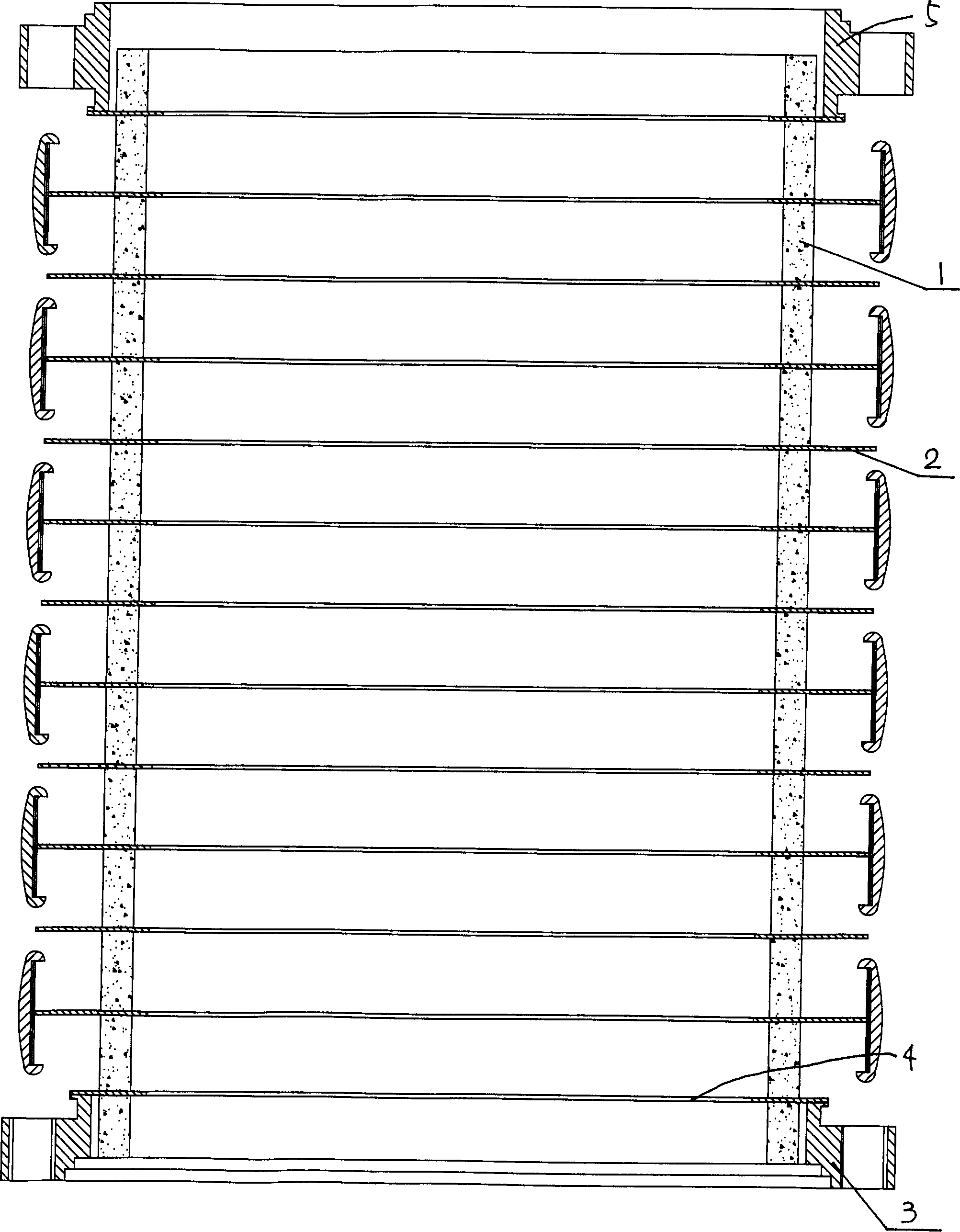

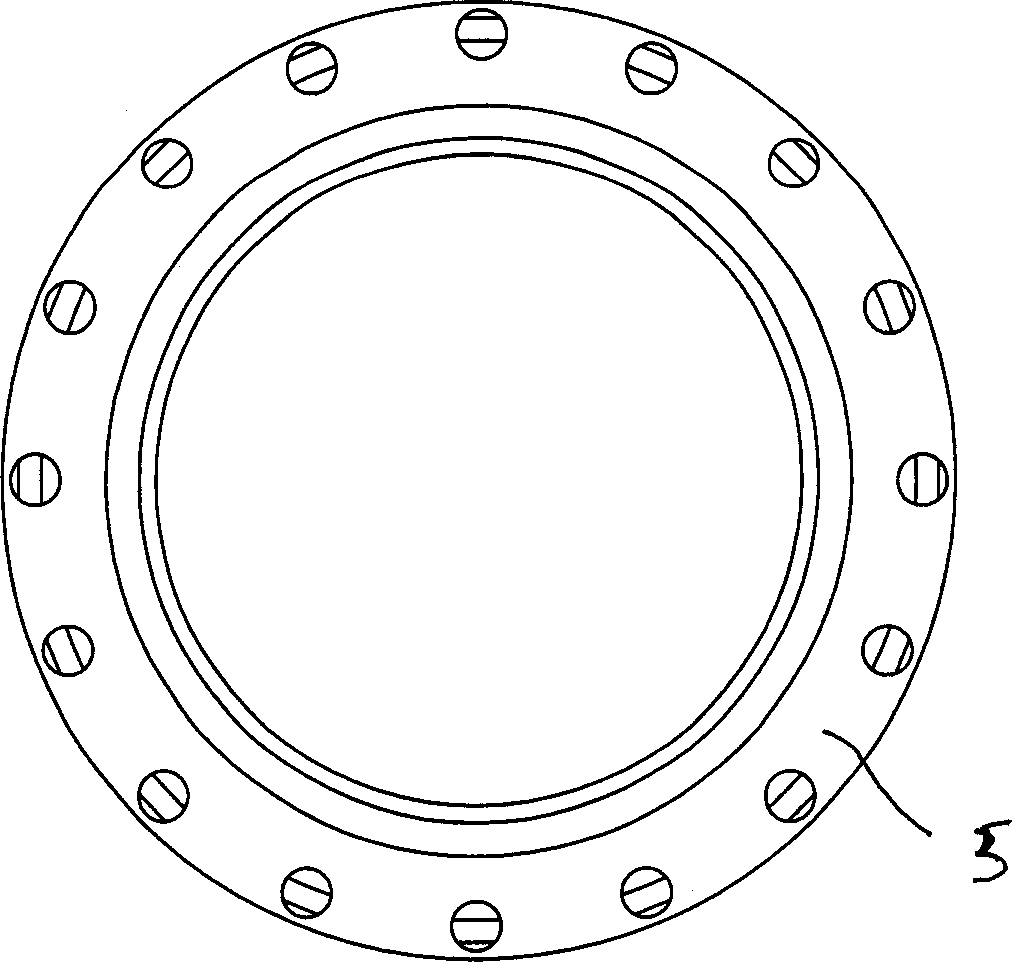

[0012] Such as figure 1 , figure 2 The high-voltage accelerating tube shown is formed by stacking a plurality of connection rings 1 and electrode sheets 2 sandwiched between two adjacent connection rings 1. The center of the electrode sheet 2 has a central hole 4, so The above-mentioned electrode sheet 2 and the above-mentioned connecting ring 1 are arranged concentrically.

[0013] The material of the electrode sheet 2 is titanium. The material of the connecting ring 1 is ceramics.

[0014] Aluminum foil is clamped between the ceramic connection ring 1 and the titanium electrode sheet 2 and welded in a high vacuum solid state pressure diffusion welding furnace. The welding is between the connecting ring 1 and the electrode sheet 2, applying a pressure of 30-50 tons to the acceleration tube along its axial direction, and the vacuum degree is better than 5 × 10-4Pa, and the temperature is 600~ Under the condition of 650° C., the aluminum atoms diffuse into the titanium ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com