Traction and suspension system

A traction system, suspension technology, applied in the direction of suspension, elastic suspension, transportation and packaging to achieve the effect of improving initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

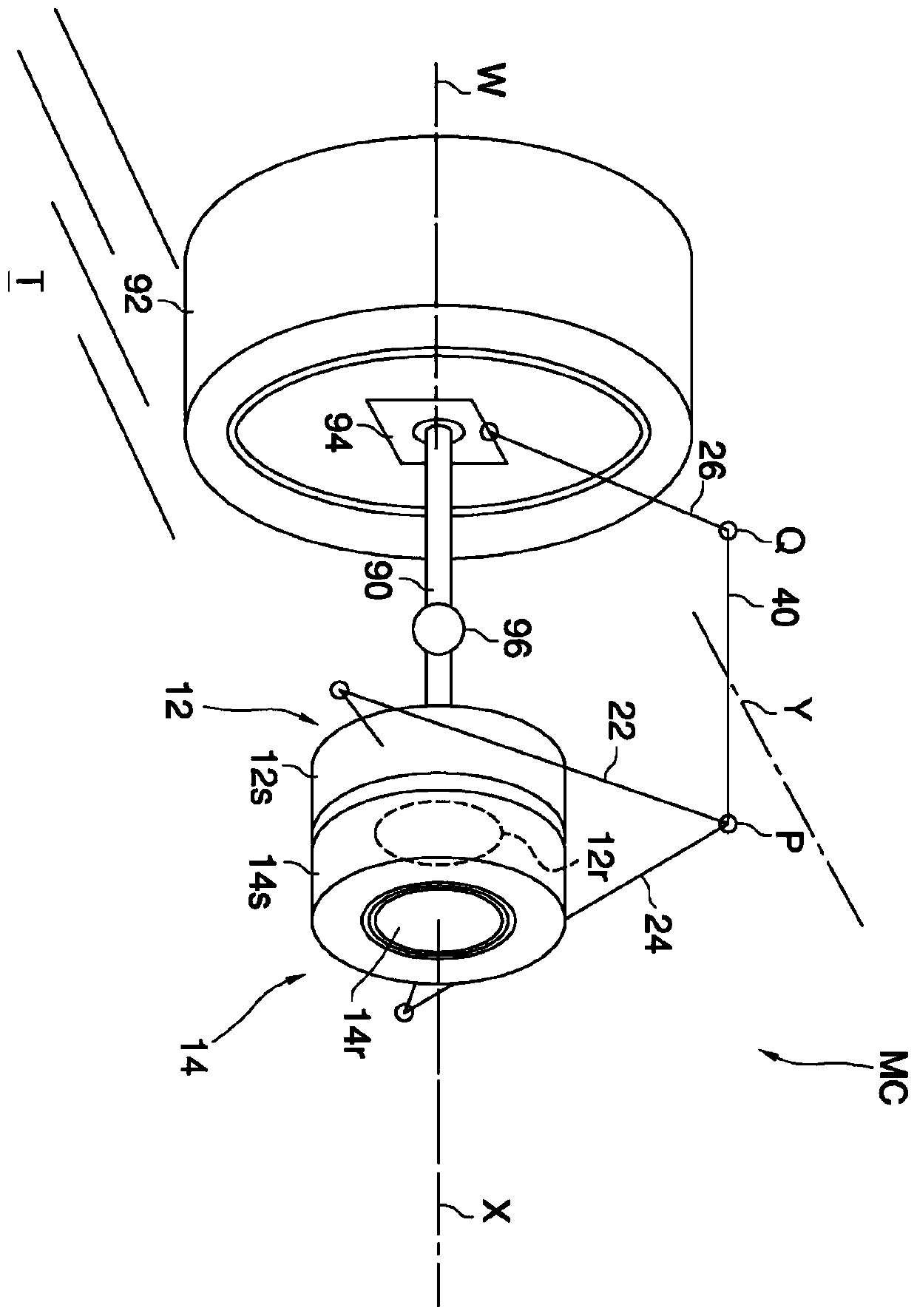

[0065] The illustrated system MC is used to rotate a propulsion element in the form of a wheel. By rolling over the terrain T, the wheels move an associated vehicle (not shown). For example the system MC is replicated on all wheels of the vehicle.

[0066] System MC comprises two identical rotary electric motors 12 , 14 capable of rotating a wheel 92 by means of a shaft 90 .

[0067] The two electric motors 12, 14 are formed by respective stators 12s, 14s and respective rotors 12r, 14r.

[0068] The rotors 12r, 14r are coaxial and have a common axis of rotation denoted X. The X-axis is fixed relative to the frame of the vehicle, for example by mounting the rotors 12r, 14r and / or the shaft 90 on ball bearings (not shown) with rings integral to the frame.

[0069] Each stator 12s, 14s is connected to a respective rigid arm 22, 24, and the arms 22, 24 are connected to a common point P external to the motors 12, 14.

[0070] Point P belongs to or is connected to the end of lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com