Microfluidic device and method for loading fluid in microfluidic device

A microfluidic, fluid technology, used in chemical instruments and methods, fluid controllers, laboratory utensils, etc., that can solve problems such as methods for measuring or controlling input volumes that are not described

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Accordingly, embodiments of the present invention will now be described with reference to the drawings, wherein like reference numerals may be used to refer to like elements throughout. It should also be understood that the drawings are not necessarily to scale.

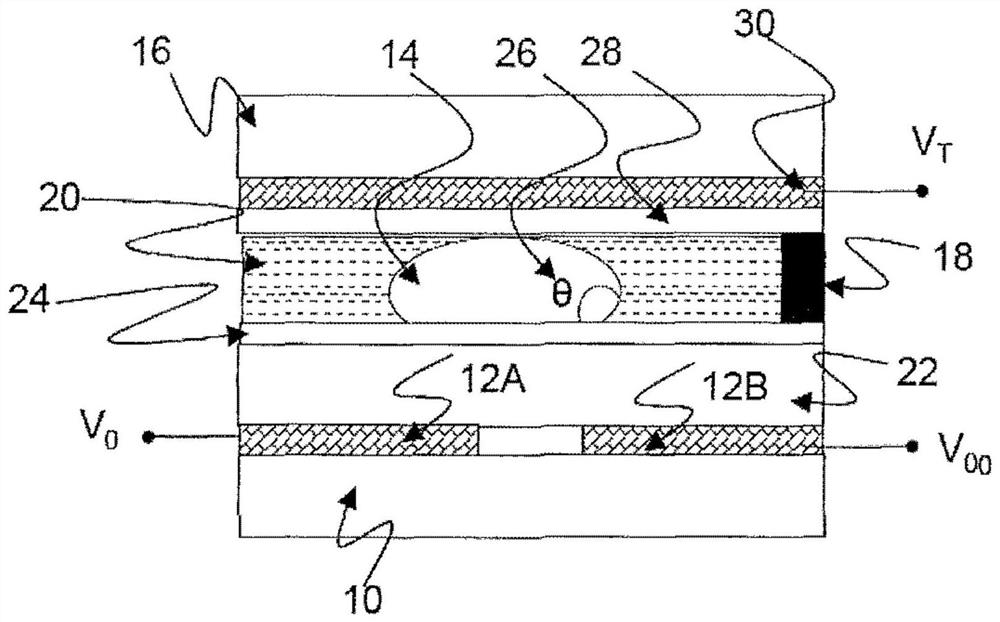

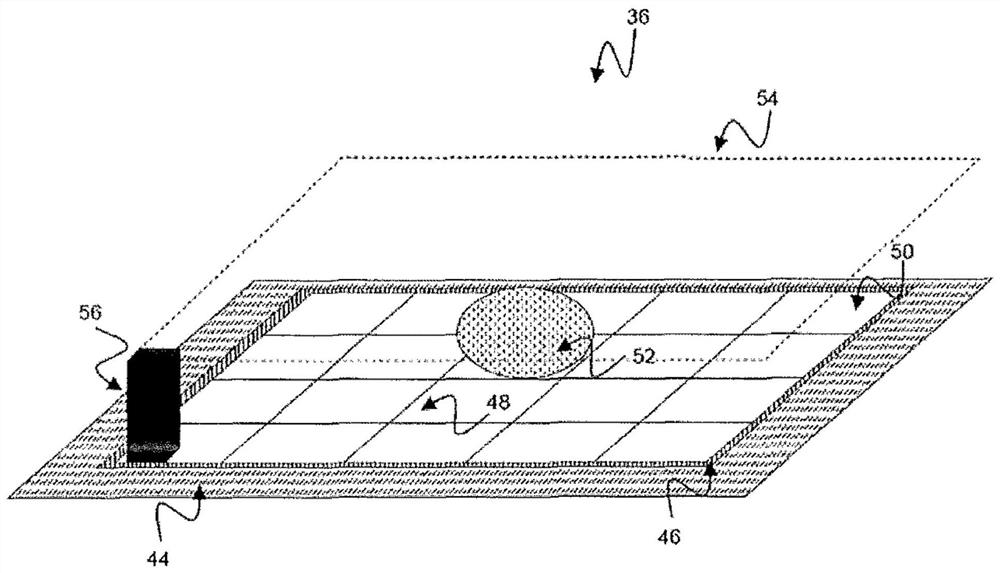

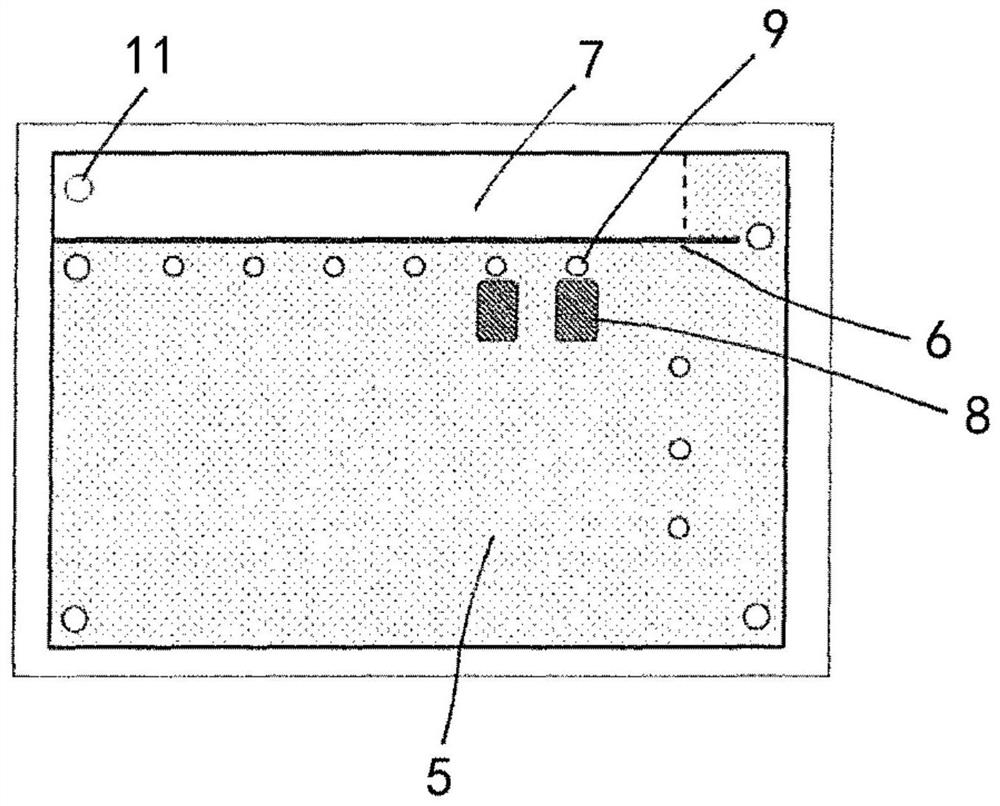

[0087] It has been recognized that although image 3 The microfluidic devices of GB 2542372 / WO 2017 / 047082 shown in Two problems may arise in (as required in some applications of this device).

[0088] exist image 3 One problem that can arise in devices that are loaded into the fluid chamber is that if the total volume of the fluids (filler fluid and working fluid) loaded into the fluid chamber is less than the total volume of the fluid chamber of the device, bubbles of air (or other exhaust fluid) will remain in the within the device. As long as the device is kept at a uniform temperature (e.g., at room temperature) and the cell gap of the device is relatively uniform, this bubble will remain in a contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com