Long-strip-shaped injection molded part

A technology of injection molded parts and long strips, which is applied in the field of long strips of injection molded parts, can solve problems such as weak bonding, easy falling off, and inability to ensure order, and achieve high appearance quality, firm combination, and high product appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

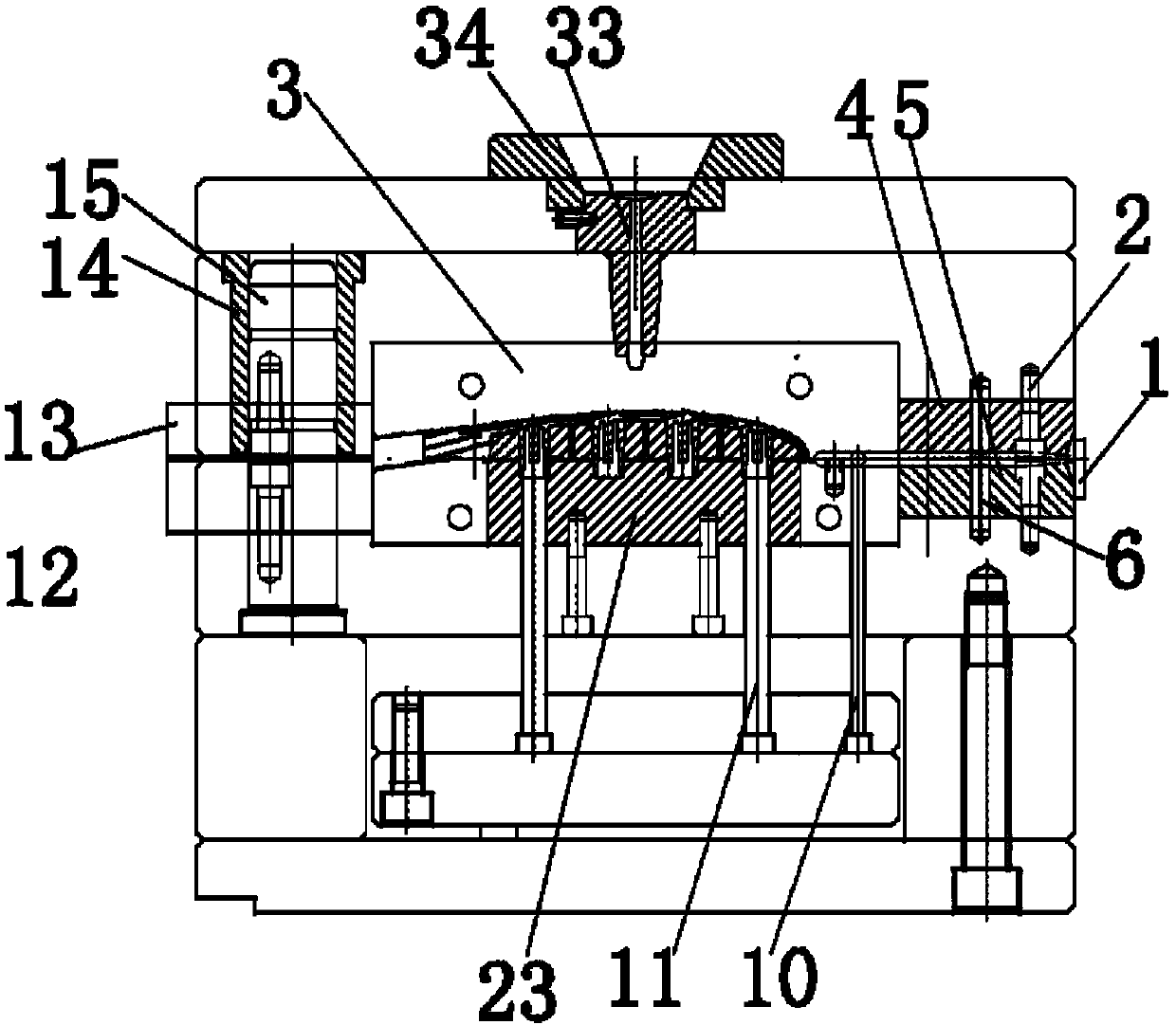

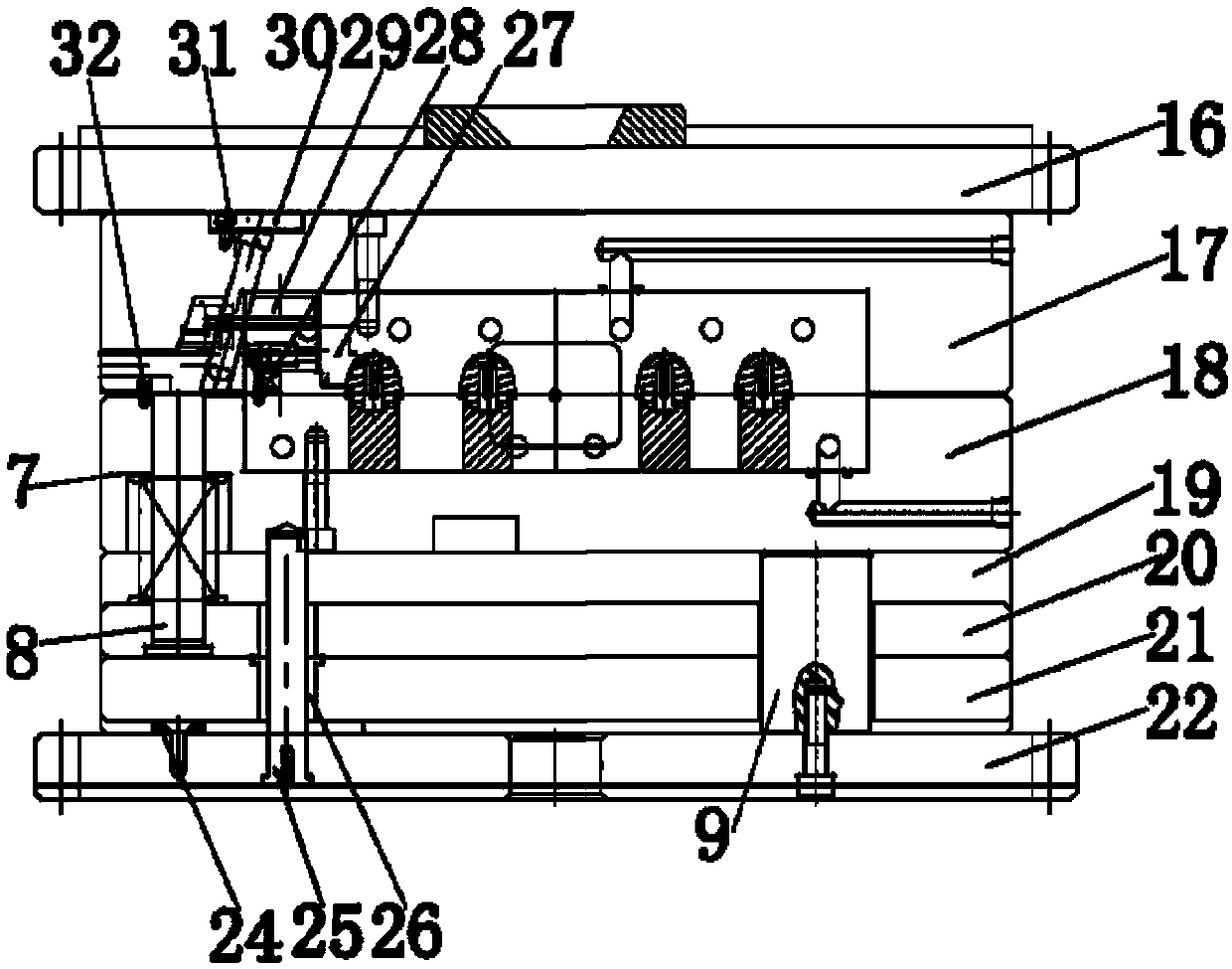

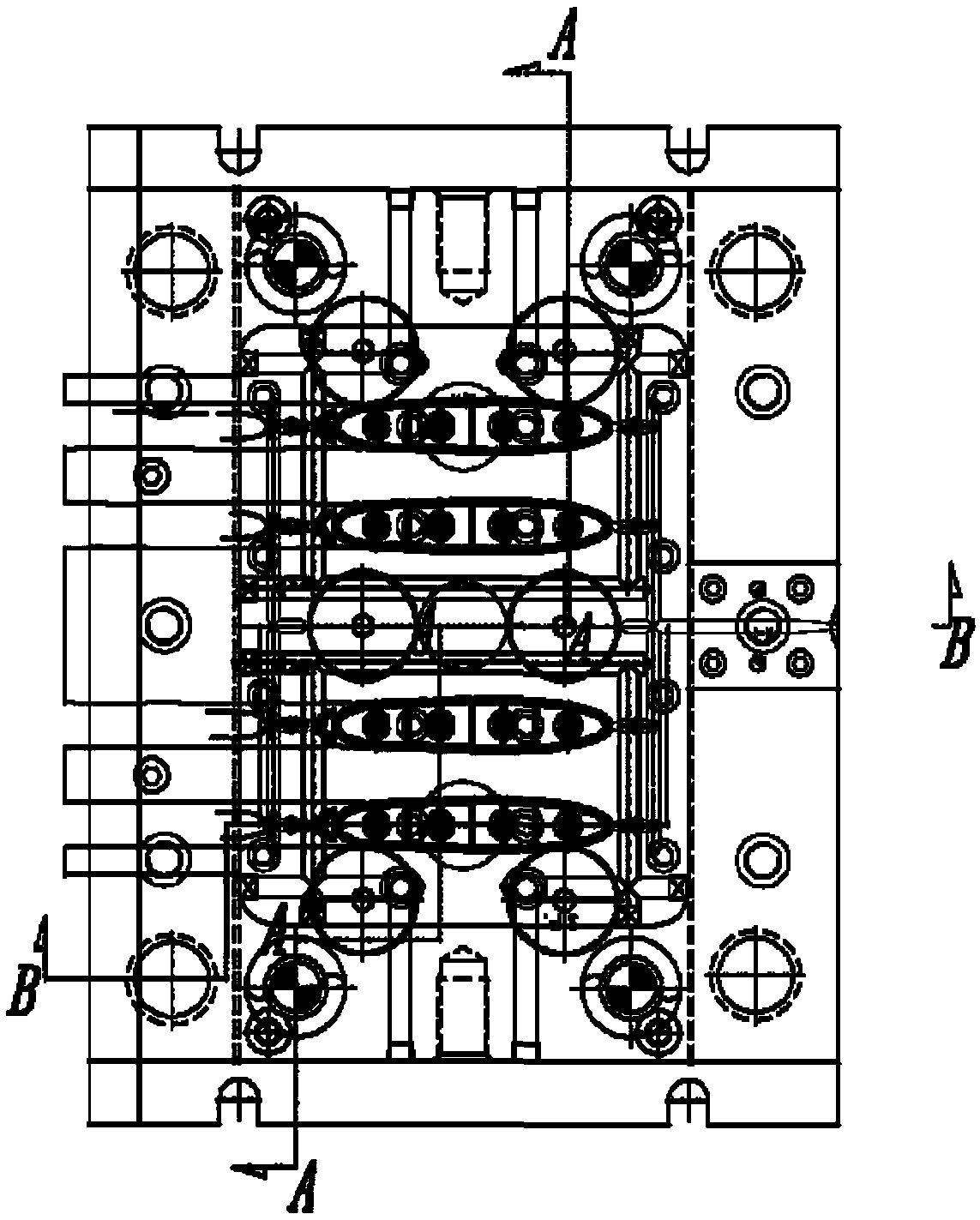

[0019] Figure 1-4 Shown is the relevant explanatory drawing of the present invention; A kind of specific embodiment of secondary injection molding mold is, as figure 2 , image 3 , Figure 4 As shown, a secondary injection molding mold includes side positioning ring 1, sprue sleeve fastening screw 2, cavity insert 3, upper half ring sprue sleeve 4, lower half ring sprue sleeve 5, gate Set positioning pin 6, reset rod spring 7, reset rod 8, support column 9, runner ejector rod 10, A rubber ejector rod 11, positioning insert 12 under the skeleton body, positioning insert 13 on the skeleton body, guide sleeve 14, Guide column 15, panel 16, fixed formwork 17, movable formwork 18, die foot 19, thimble cover plate 20, thimble push plate 21, bottom plate 22, core insert 23, garbage nail 24, thimble plate guide post 25, thimble plate Guide sleeve 26, slider head 27, slider spring 28, slider body 29, oblique guide post pressing plate 30, oblique guide post 31, slider limit screw 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com