Dust storage and separation equipment for gravel conveyor

A separation equipment and conveyor technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as endangering the health of operators, environmental pollution, resource loss, etc., to ensure stability and improve stability. , the effect of preventing resource loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

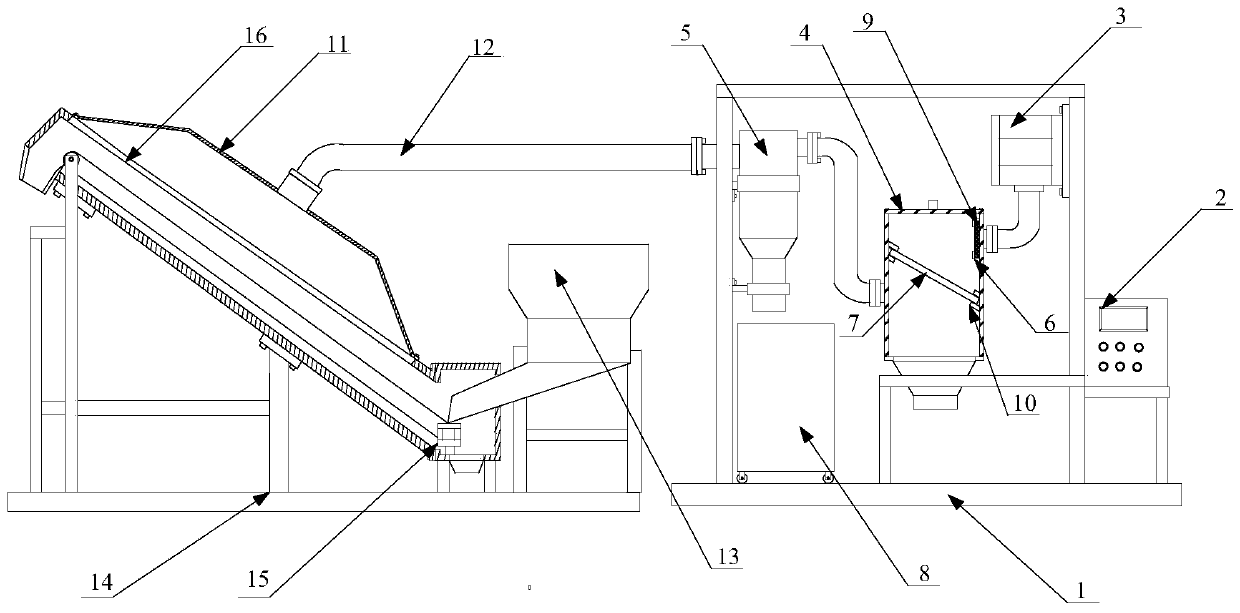

[0027] like figure 1 As shown, a dust storage and separation device for gravel conveyors of the present invention includes a transmission body and a dust storage and separation mechanism connected to the transmission body; the transmission body in the present invention adopts a traditional transmission body, which usually includes Support 14 is arranged, the unloading mechanism 13 and feed box 16 that are installed on the bracket 14, and mechanisms such as being arranged in the feed box 16 and being connected with the delivery mechanism 13 of unloading mechanism 13. Since the transmission body is a prior art, its structure will not be repeated here. The inventive point of the present invention lies in the dust storage and separation mechanism, and the following description will focus on the structure of the dust storage and separation mechanism.

[0028] The dust storage and separation mechanism such as figure 1 As shown, it includes a mounting frame 1, a dust collection cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com