A kind of oxalic acid rare earth precipitation washing system

A technology of oxalic acid and rare earth, which is applied in the field of oxalic acid rare earth precipitation washing system, can solve problems affecting product yield, casualty equipment, loss of rare earth resources, etc., to avoid casualty and equipment damage, good safety performance, and shorten production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

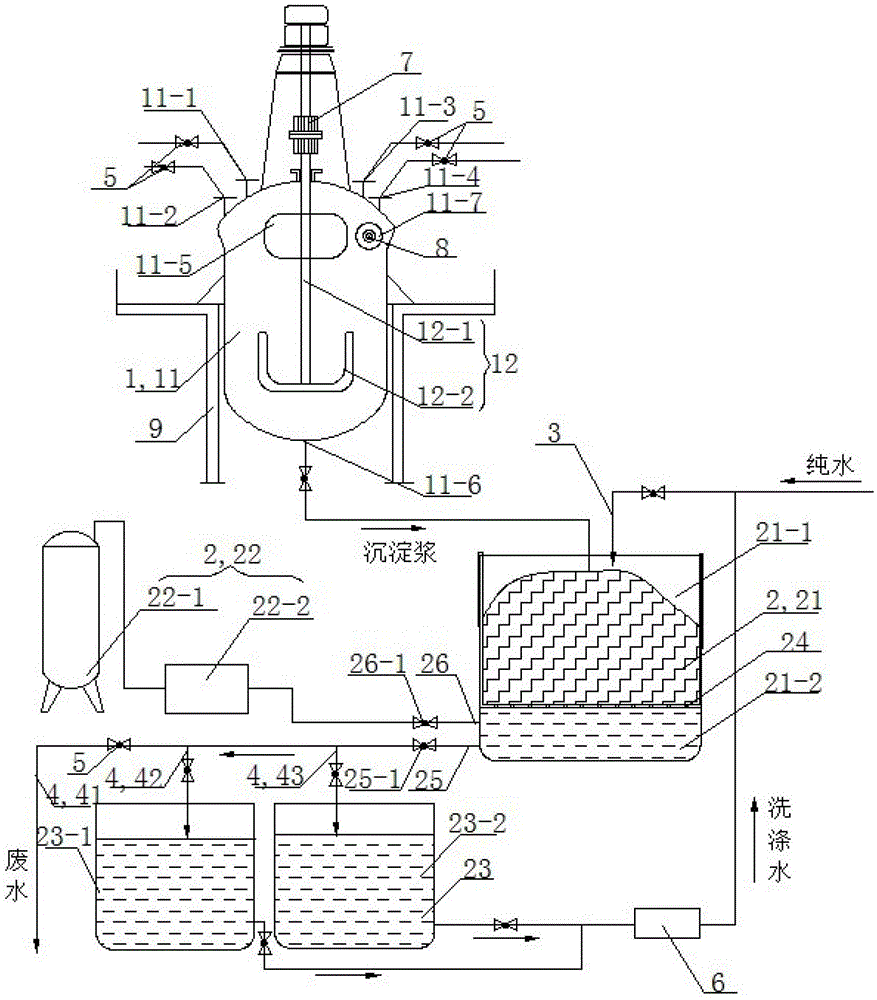

[0025] See figure 1 , the present invention has oxalic acid rare earth reactor 1 and precipitation washing device 2; Reactor 1 is positioned at the top of precipitation washing device 2, and reactor 1 is connected with precipitation washing device 2 through pipeline; 22, water collection bucket 23, filter bucket 21 bottom is provided with drainage pipe 25 and exhaust pipe 26, the other end of drainage pipe 25 and exhaust pipe 26 is connected with water collection bucket 23 and vacuum pumping device 22 respectively, and filter bucket 21 top is provided with pure Water import 3.

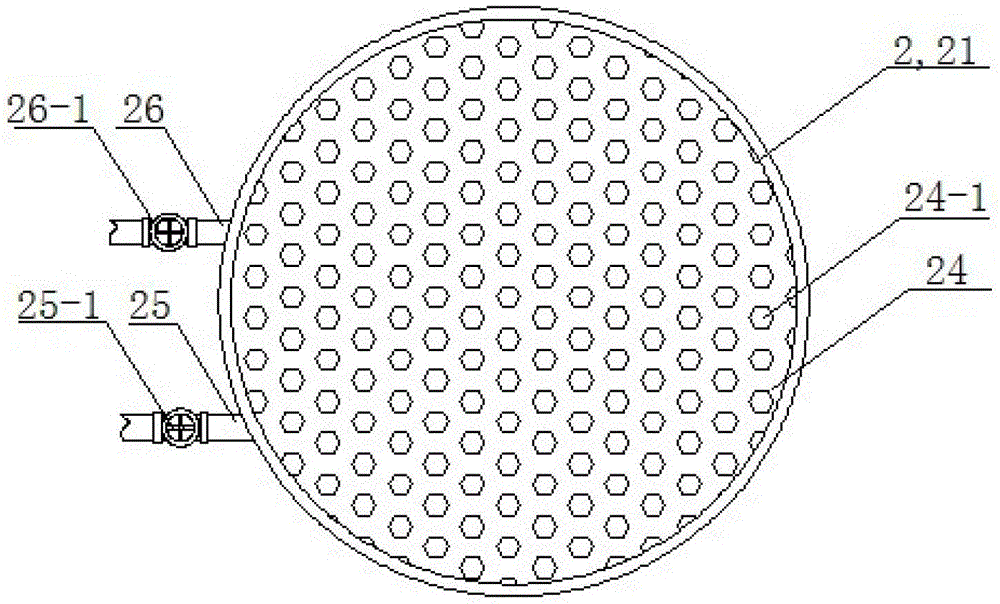

[0026] See figure 2 , the middle and lower part of the filter bucket 21 is provided with a partition 24, and a plurality of through holes 24-1 are provided on the partition 24. The partition 24 divides the filter bucket 21 into two parts, including the upper sedimentation chamber 21-1 and the lower water storage Cavity 21-2, the settling chamber 21-1 is surrounded by a filter cloth, the water storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com