A Vertical Line Production Process for Ductile Iron Molds with Large Differences in Wall Thickness

A technology of ductile iron parts and vertical lines, which is applied in the field of vertical line production of ductile iron molds with large differences in wall thickness, and can solve problems such as low production efficiency, easy shrinkage cavity, and cold shut at thin-walled positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

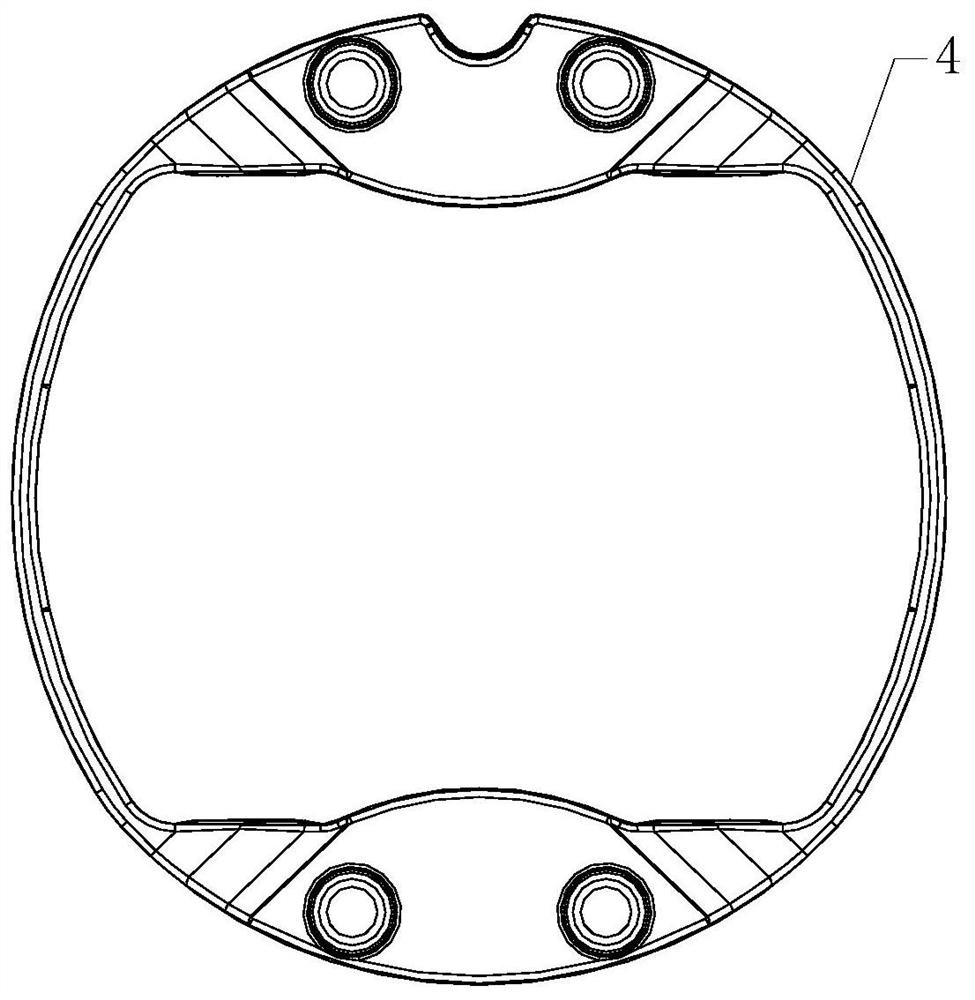

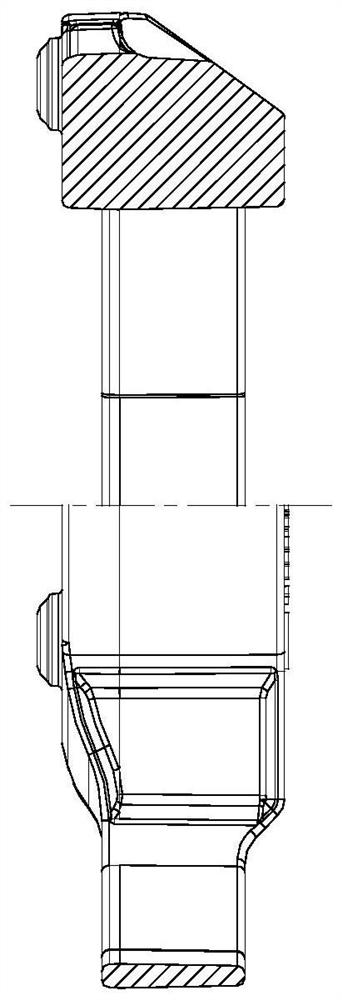

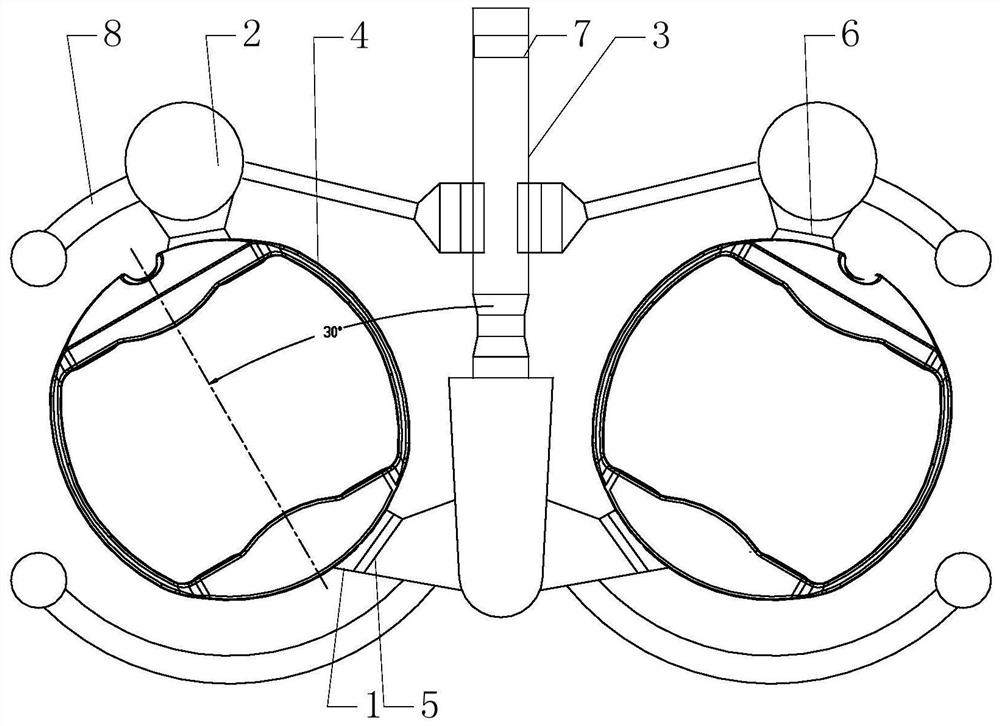

[0024] figure 1 It is a front view of an embodiment of a ductile iron part with a large difference in wall thickness, figure 2 It is a cross-sectional view of an embodiment of a ductile iron part with a large difference in wall thickness, image 3 It is a schematic diagram of the process of producing ductile iron molds with large wall thickness differences in vertical lines according to the present invention. As shown in the figure, a process for producing ductile iron molds with large wall thickness differences in vertical lines includes a pouring device, and the pouring device includes gates Component 1, riser component 2 and sprue 3 arranged vertically, the sprue component and the riser component are all inclined upward to the sprue, and all communicate with the sprue through the pipeline, so that the pouring liquid in the sprue can pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com