Assembly type limiting welding platform for machining of large-scale welding part

A welding platform and welding piece technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of low work efficiency, high work difficulty, time-consuming and laborious, etc., and achieve the effect of improving work efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

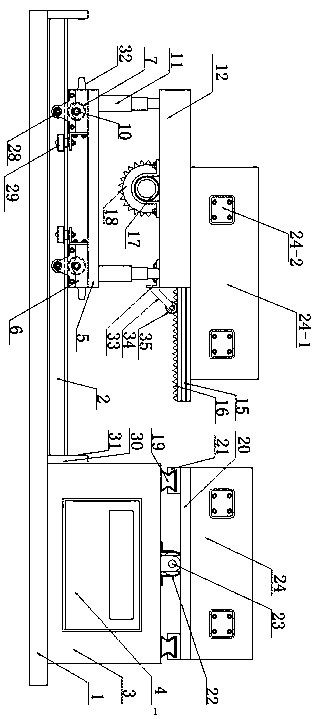

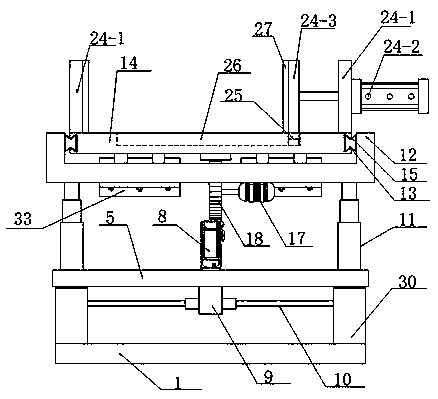

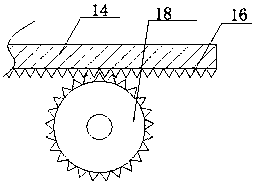

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see as Figure 1-Figure 5As shown, the technical solution adopted in this specific embodiment is: the front and rear sides of the upper part of the bottom plate 1 are symmetrically fixed with an I-shaped steel track 2 by bolts, and the bottom plate 1 on the right side of the I-shaped steel track 2 is fixedly welded with a fixed platform 3 , the middle part of the fixed platform 3 is fixedly embedded with an electric control box 4, and the inside of the electric control box 4 has a power supply, a KS02Y controller and a control switch to supply power and control the electrical components inside the device; it also includes a wheel base 6, Walking wheel 7, No. 1 motor 8, No. 2 motor 17, fixed mount 12, No. 1 adjusting plate 14 and No. 2 adjusting plate 20; Each corner is fixed with a wheel base 6 by bolts, the wheel base 6 is a box body with a hollow structure wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com