Tool fixture and system for bevel grinding and polishing and bevel grinding and polishing method

A bevel and fixture technology, applied in the field of polishing and grinding, to achieve the effects of saving equipment costs, visible processing, and protecting the bevel angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

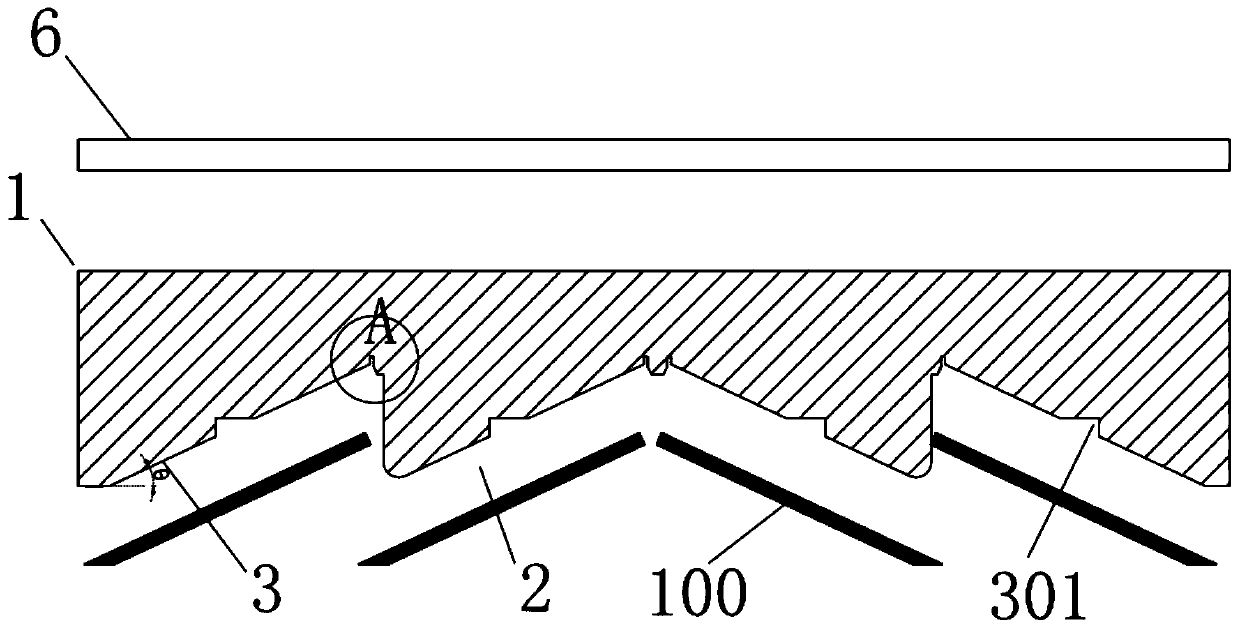

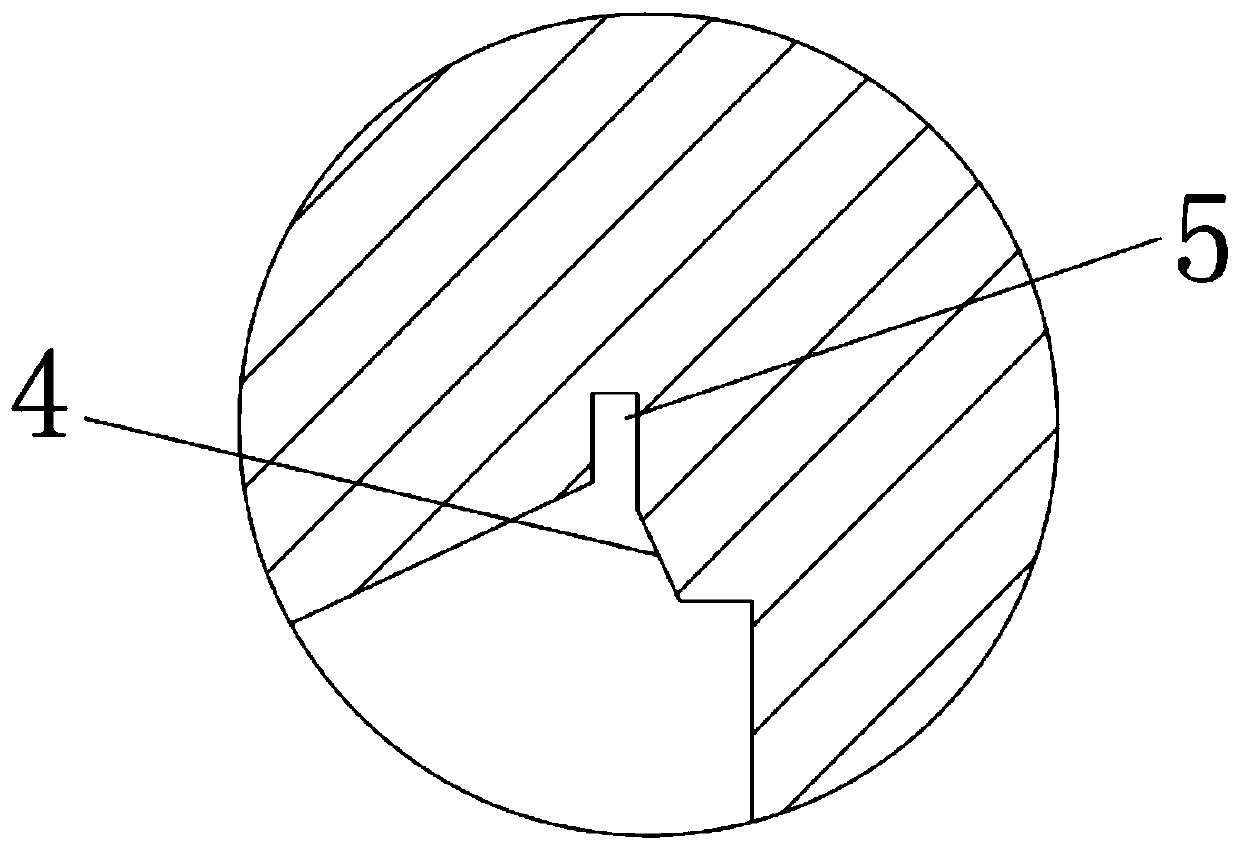

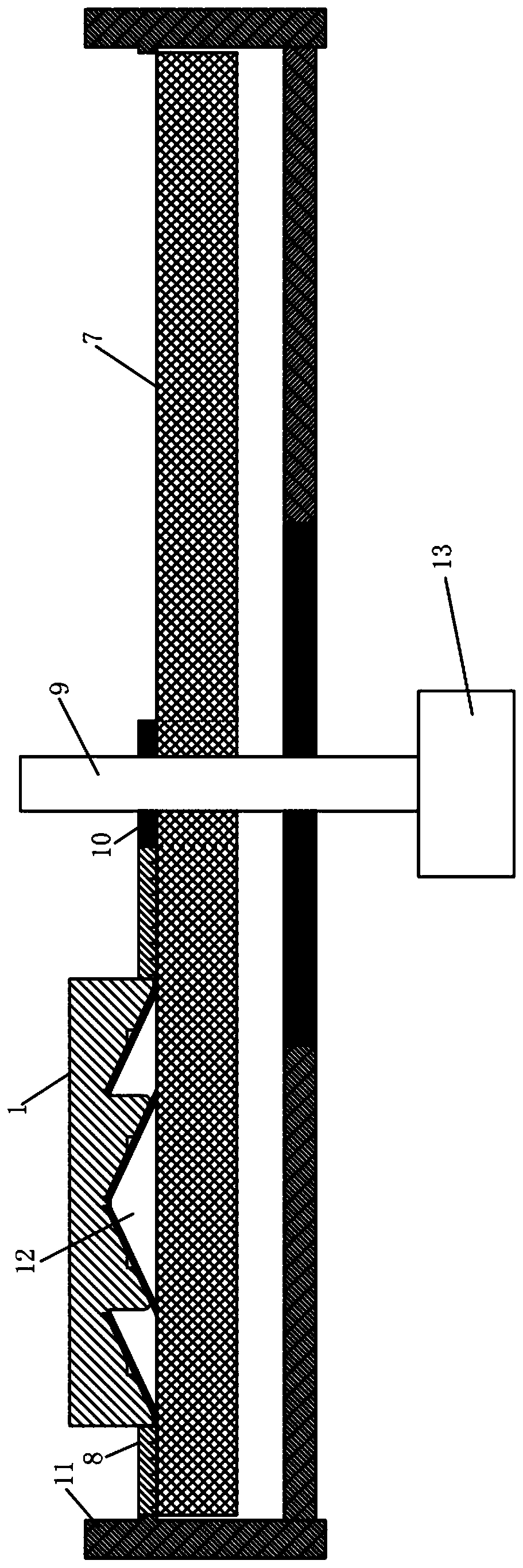

[0029] A kind of bevel grinding and polishing fixture, such as Figure 1 to Figure 4 As shown, it includes a rectangular parallelepiped fixture body 1, the lower end of the fixture body 1 is provided with a number of notch grooves 2, and the notch grooves 2 can be one of right-angled triangular notch grooves, acute-angle triangular notch grooves or obtuse-angle triangular notch grooves. one or more, or other irregularly shaped notch grooves; at least one side of the notch groove 2 is a flat fitting surface 3 inclined downward, and the top of the fitting surface 3 is fixed with a corresponding top bezel4. Attaching the substrate 100 to be ground on the surface of the bonding surface 3 can ensure the inclination of the substrate 100, so that during the processing, the slope to be processed of the substrate 100 is guaranteed to be in the vertical direction relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com