Concrete mixing device for bridge construction

A stirring device and a technology for construction, applied in the field of bridge construction, can solve problems such as uneven stirring, self-solidification and deposition, and achieve the effects of ensuring mixing quality, avoiding self-solidification and deposition, and improving quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

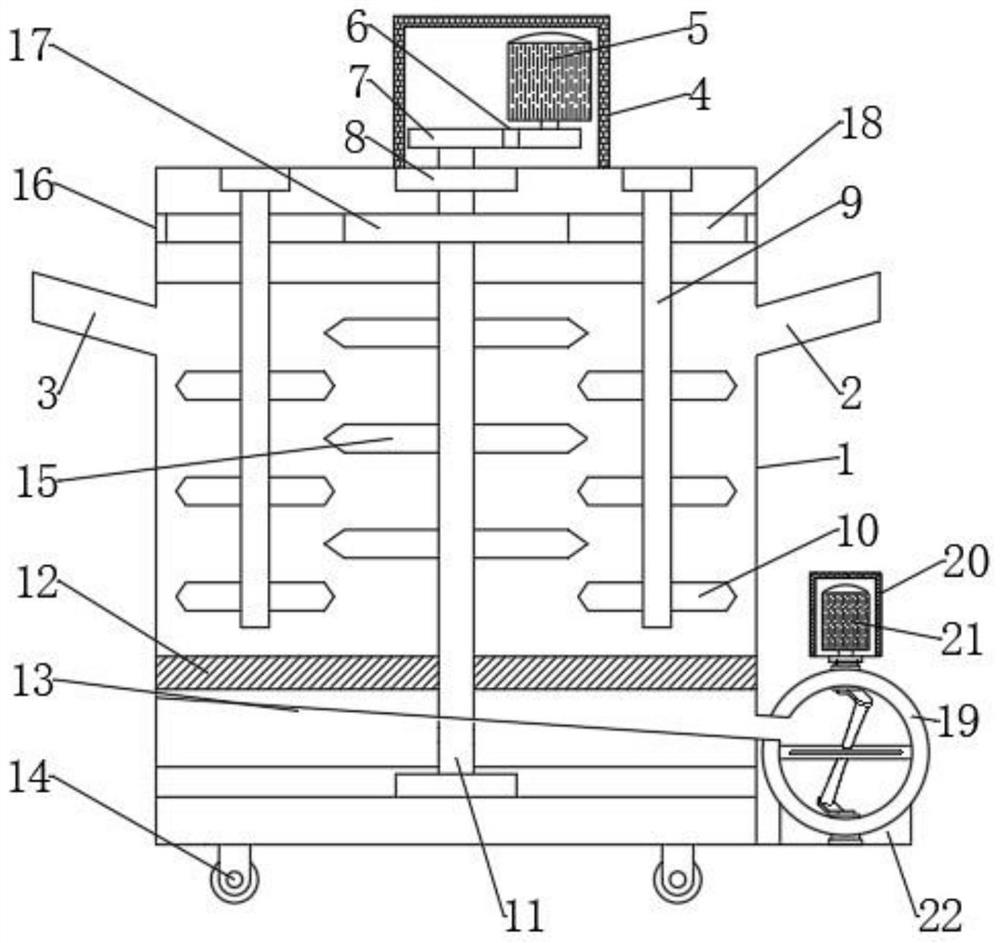

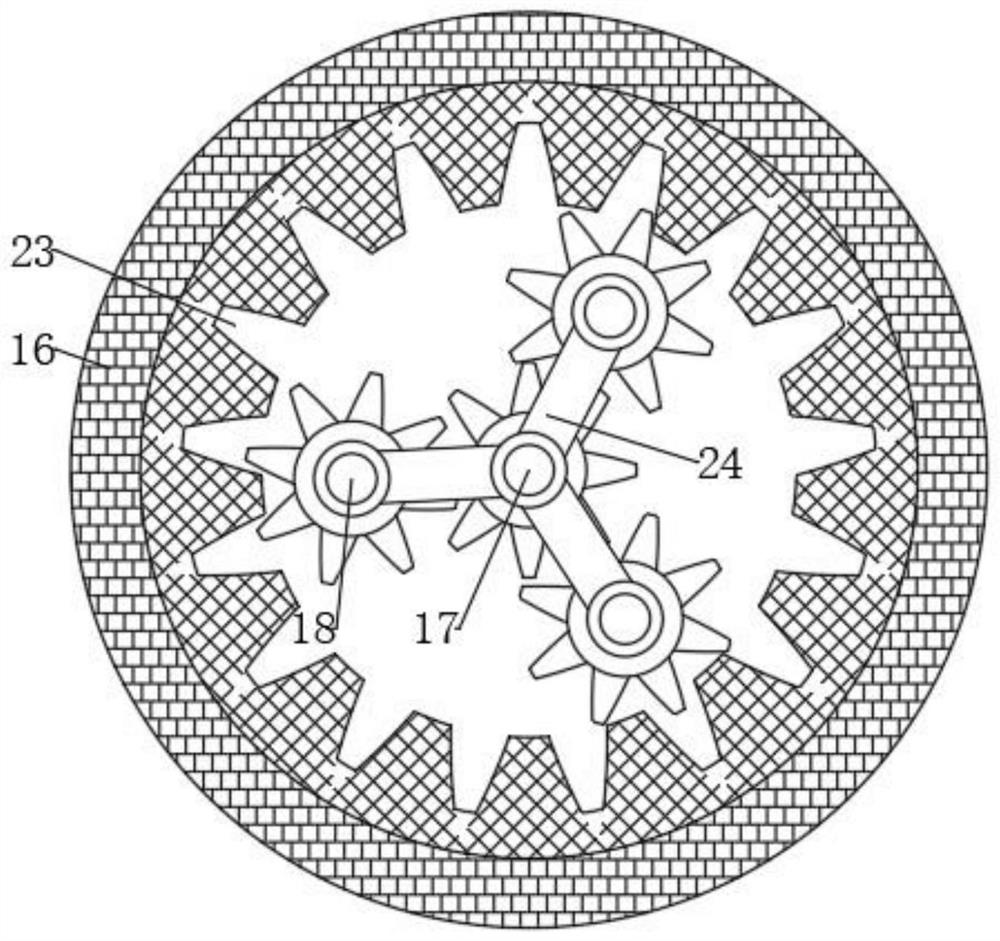

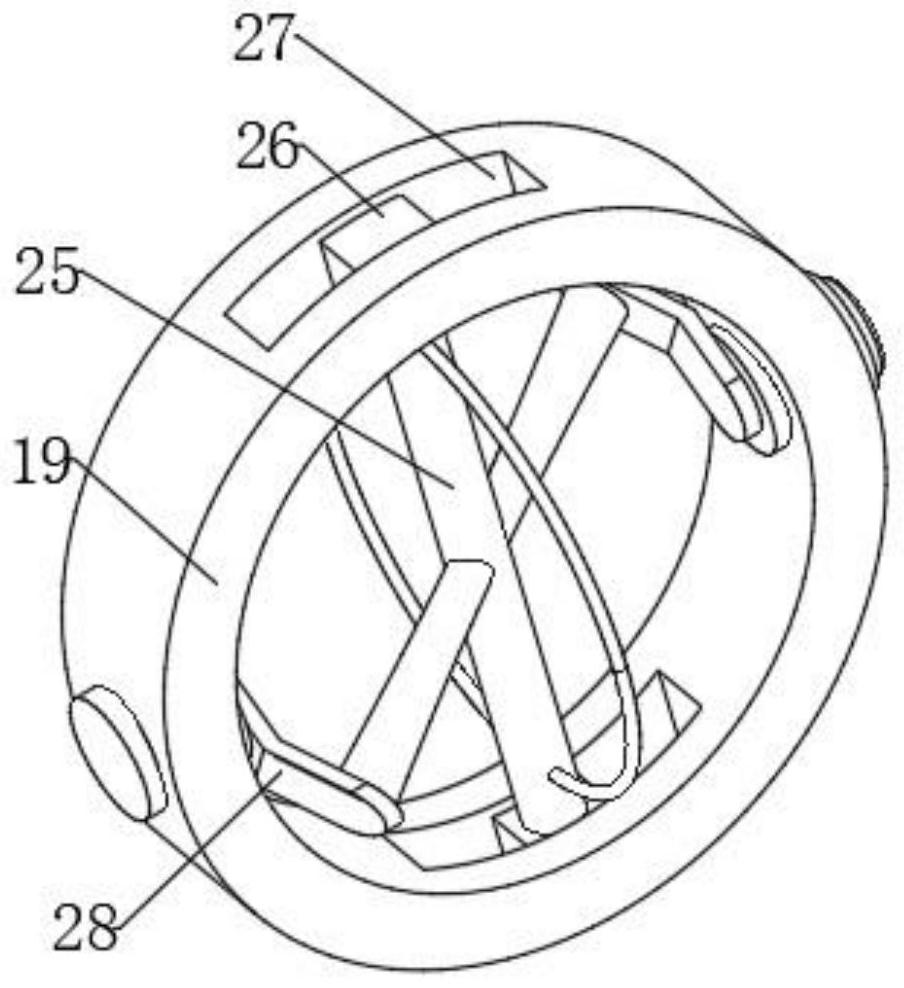

[0020] see Figure 1-3 , a concrete mixing device for bridge construction, comprising a cavity 1, a first material inlet 2 and a second material inlet 3 are respectively arranged on the left and right sides of the cavity 1, and a stirring shaft 11 is arranged in the cavity 1. A plurality of stirring blades 15 are equidistantly arranged on the shaft 11, and the stirring shaft 11 is fixed inside the cavity 1 by a fixed bearing 8, and one end of the stirring shaft 11 extends to the outside of the cavity 1 and is connected with a driving mechanism; the stirring shaft A plurality of driven shafts 9 are evenly arranged on the periphery of 11, the number of driven shafts 9 is not less than three, the driven shaft 9 is connected to the stirring shaft 11, and a plurality of driven blades are equidistantly arranged on the driven shaft 9 10. A detachable baffle 12 is arranged inside the cavity 1 , and an inclined discharge platform 13 is arranged below the baffle 12 , and the discharge p...

Embodiment 2

[0030] In Embodiment 1, the cavity 1 is placed on the ground during actual use, and it takes a lot of manpower to move or place the equipment; therefore, this embodiment is improved on the basis of Embodiment 1. It is: a roller 14 is arranged below the cavity 1, so as to facilitate the movement and placement of the stirring device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com