Check block layout system of powder forming machine and powder forming machine

A technology of forming machine and block, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., to achieve the effects of simple machine operation, reduction of production cost, and reduction of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

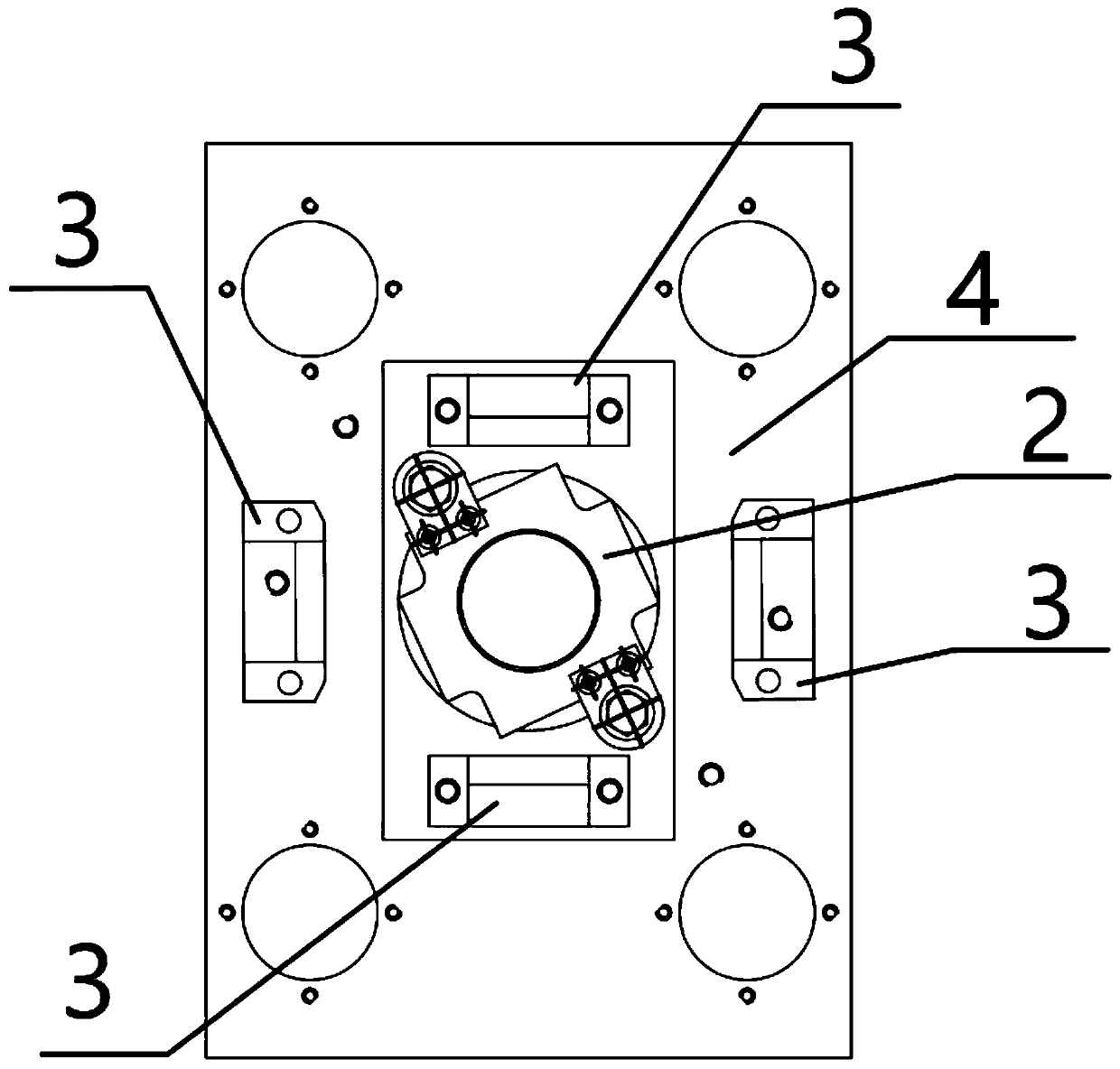

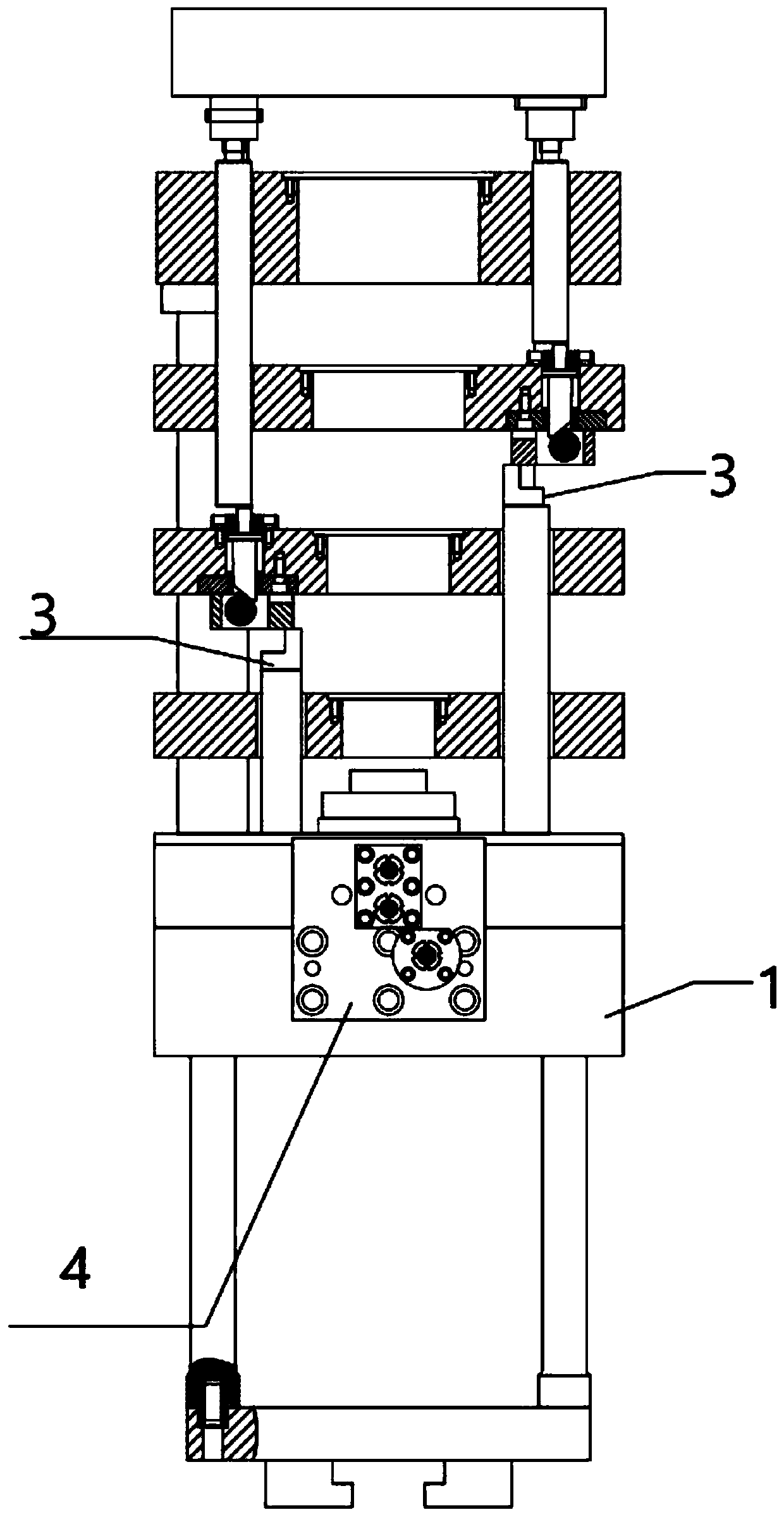

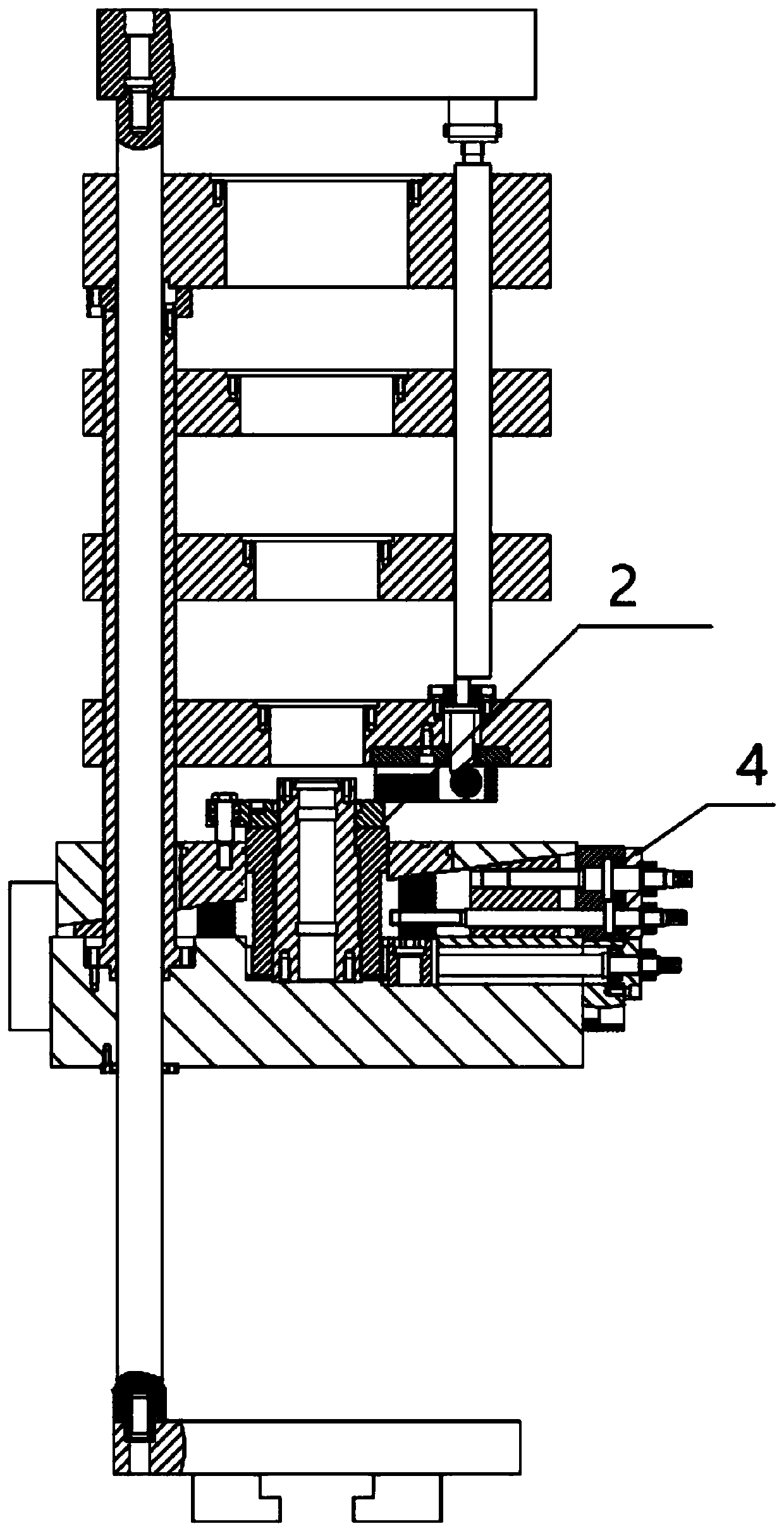

[0036] Such as figure 1 , figure 2 and image 3 As shown, the block layout system includes a base plate 1, side blocks 3, center block 2 and block forming adjustment device 4; side block 3, center block 2 and block forming adjustment device 4 are all installed on the base plate 1 The center block 2 is arranged at a position close to the geometric center of the bottom plate 1, and the side blocks 3 are arranged around the center block; the block forming adjustment device 4 corresponding to the center block 2 is arranged on a group of side blocks 3 that are arranged symmetrically Within the range of the included angle between the connecting line of the geometric center and the connecting line of the geometric center of another group of symmetrically arranged side stoppers 3 .

Embodiment 2

[0038] Such as Figure 5 , Figure 6 and Figure 7 As shown, a layout system of five lower punch blocks includes a bottom plate 1, two lower punch blocks 31, three lower punch blocks 32, four lower punch blocks 21, block forming adjustment device 4, and block forming adjustment plate 492. The block forming adjustment device 4 is installed on the block forming adjustment plate 492, the second lower punch block 31, the third lower punch block 32, the fourth lower punch block 21 and the block forming adjustment plate 492 are all installed on the base plate 1; The four lower punch blocks 21 are arranged near the geometric center of the base plate 1, the second lower punch block 31, and the third lower punch block 32 are arranged around the four lower punch blocks 21; the corresponding blocks of the four lower punch blocks 21 are formed The adjustment device 4 is arranged within the angle range between the geometric center connecting line of a group of symmetrically arranged two...

Embodiment 3

[0040] Such as Figure 4 , Figure 6 and Figure 7As shown, a layout system of five lower punch blocks includes a bottom plate 1, two lower punch blocks 31, three lower punch blocks 32, four lower punch blocks 21, block forming adjustment device 4, and block forming adjustment plate 492. The block forming adjustment device 4 is installed on the block forming adjustment plate 492, the second lower punch block 31, the third lower punch block 32, the fourth lower punch block 21 and the block forming adjustment plate 492 are all installed on the base plate 1; The four lower punch blocks 21 are arranged near the geometric center of the base plate 1, the second lower punch block 31 and the third lower punch block 32 are arranged around the four lower punch blocks 21; a group of symmetrically arranged second lower punch blocks 31 The connecting line of the geometric center of the geometric center is at a vertical angle to the connecting line of the geometric center of a group of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com