Vertical jack

A kind of jack and vertical technology, which is applied in the direction of lifting device, fluid pressure actuator, servo motor assembly, etc., can solve the problems affecting the stability of the jack, the different loading speed of the three-stage piston rod, etc., and achieve strong replaceability and guarantee The effect of high service life and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

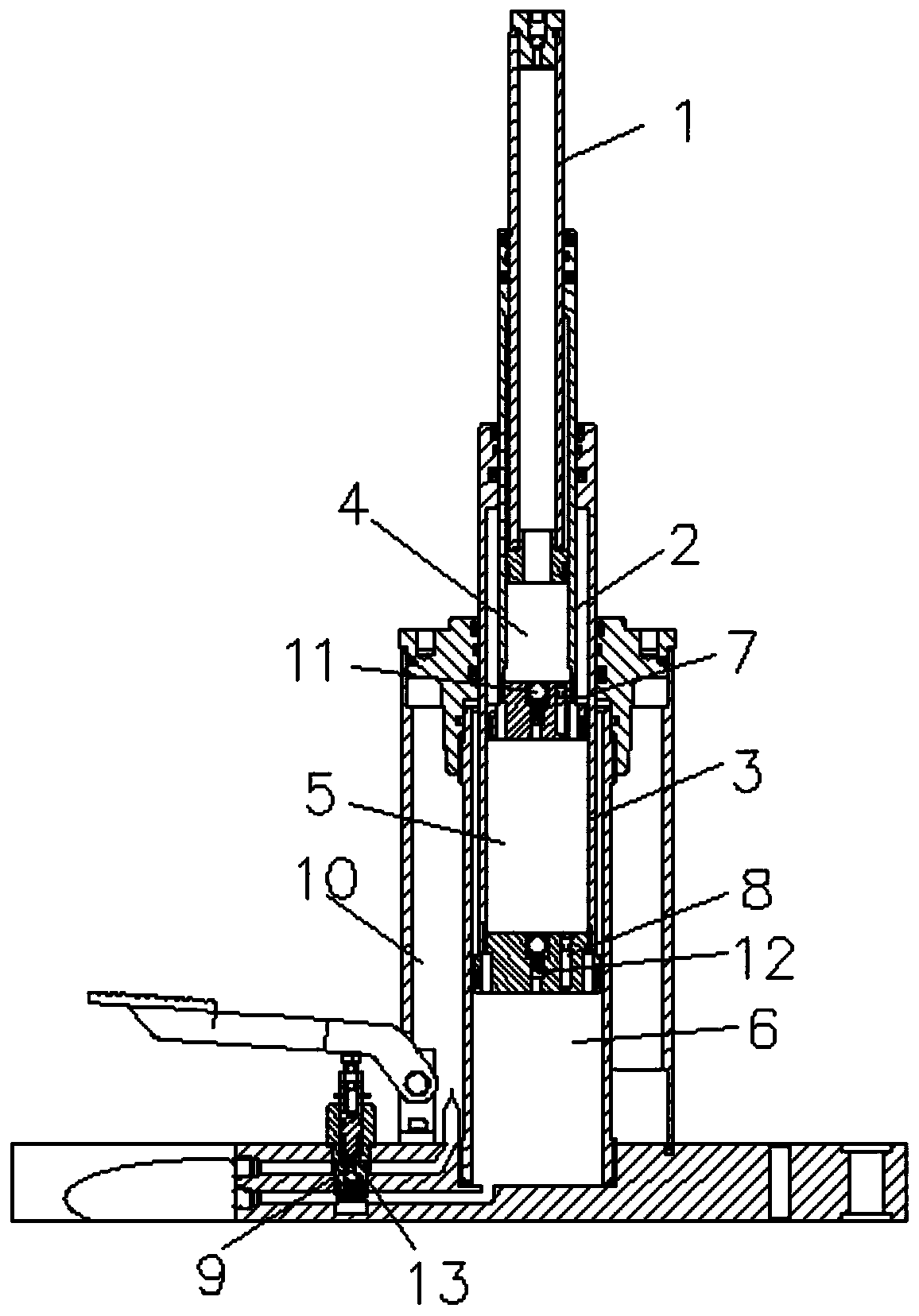

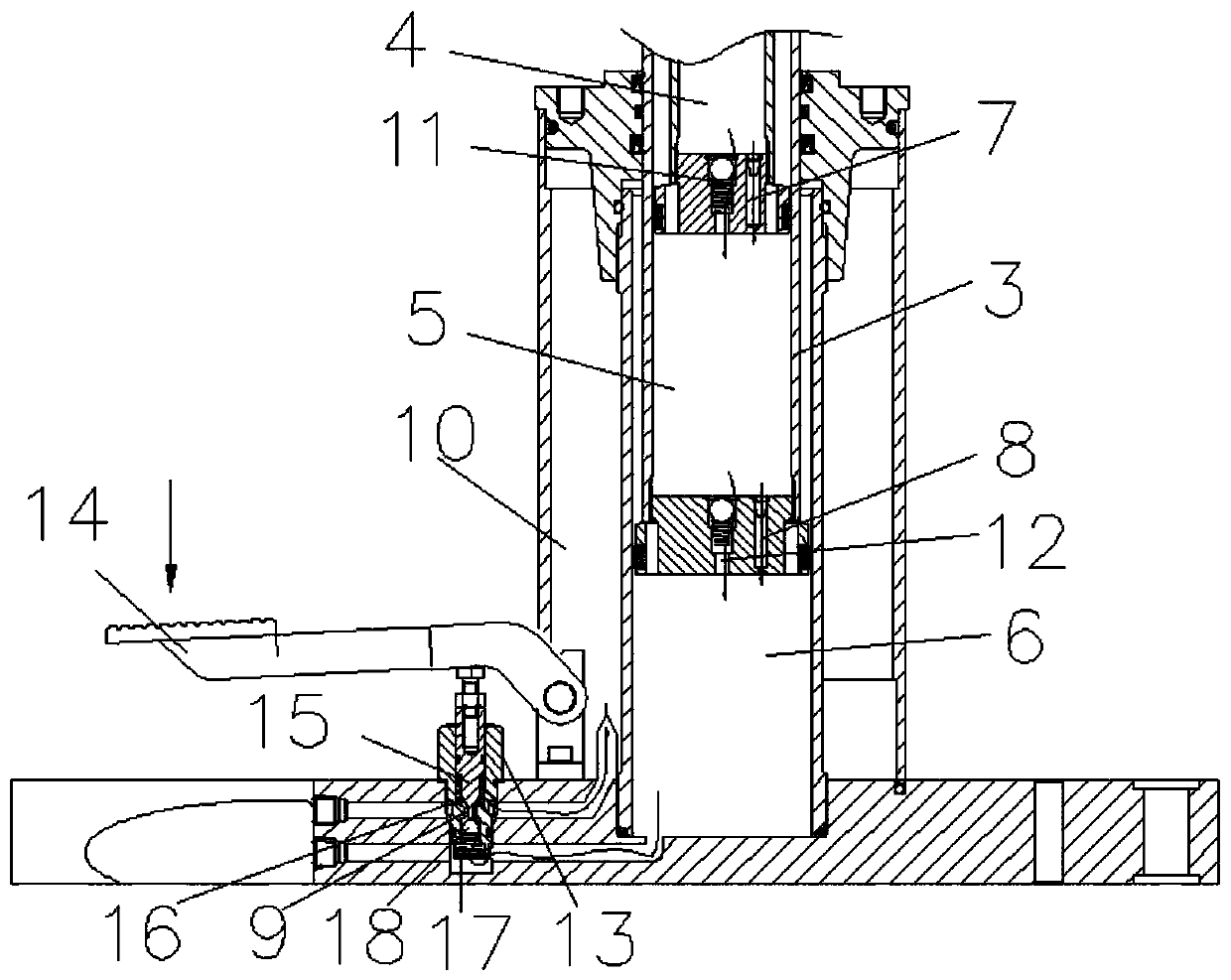

[0072] A vertical jack, comprising an outer casing cavity 10 and an oil cylinder cavity 6, the outer casing cavity 10 and the oil cylinder cavity 6 can be connected through an external oil circuit to realize oil return; the communication between the oil cylinder cavity 6 and the outer casing cavity 10 can adopt any existing technology. In order to realize the technical function of the present application, it is only necessary to ensure that the oil passage can pass through installations such as valve body components and parts with holes, so that the oil passage has small oil drainage holes.

[0073] In order to realize the load-bearing function of the jack, in this embodiment, the large piston rod 3 , the middle piston rod 2 and the small piston rod 1 are sequentially nested in the cylinder cavity 6 . Here, the characteristics of the piston rods of various sizes are: a rod-shaped member with a hollow structure that a normal piston rod has, and a piston head is arranged at one e...

Embodiment 2

[0084] In order to avoid the failure or instability of the jack, the oil drain hole is designed with a small hole structure to play a similar damping effect, so that the multi-section piston rod can be lowered slowly under load. Simultaneously, in order to realize the uniform rate of descent, this application limits the cross-sectional area of each cavity of the drain hole, defines the cross-sectional area of the drain hole-7 as S1, and the cross-sectional area of the piston rod cavity-4 as S11, S11 and S1 The ratio of A1 is A1; the cross-sectional area of oil drain hole one 7 is defined as S2, the cross-sectional area of piston rod cavity one 4 is S22, and the ratio of S22 and S2 is A2; the cross-sectional area of defined oil drain hole three 9 is S3, and the oil cylinder The cross-sectional area of cavity 6 is S33, and the ratio of S33 to S3 is A3; wherein, A1:A2:A3=1:(1.8-2.1):(3.8-4.2).

[0085] Preferably, A1:A2:A3=1:2:4, so that it is applied to jacks under...

Embodiment 3

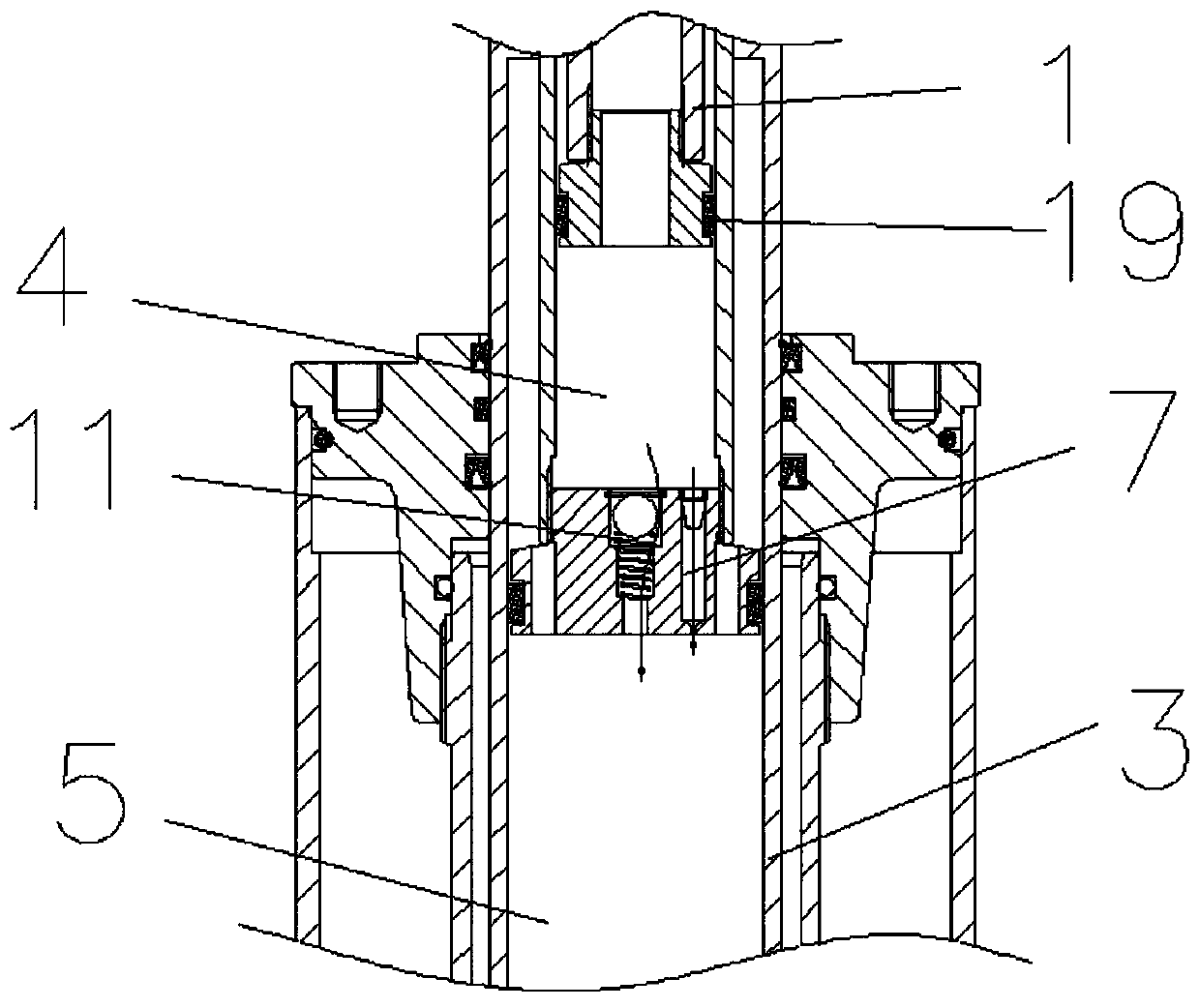

[0088] In order to realize rapid recovery of the piston rods at all levels under no load, the piston head on the middle piston rod 2 is provided with an oil return valve 11; the piston head on the large piston rod 3 is provided with an oil return valve 2 12.

[0089] Such as figure 2 As shown, the oil return valve 11 includes:

[0090] Valve body one, the valve body one has a through-hole combination connecting piston rod chamber one 4 and piston rod chamber two 5; the through-hole combination includes a ball-installation hole and a spring-installation hole coaxially arranged in sequence; wherein, The spring one mounting hole is connected to the piston rod chamber two 5, the ball one mounting hole is connected to the piston rod chamber one 4, and the diameter of the ball one mounting hole is greater than the maximum diameter of the spring one mounting hole;

[0091] Ball 1 is located in the mounting hole of ball 1, and is blocked in the mounting hole of spring 1 under the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com