Steel wire rope used for concrete precast high-intensity metal connection element, and production method for steel wire rope

A technology of metal connector and production method, applied in the field of steel wire rope, can solve the problems of difficult bending deformation and high strength of steel wire rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

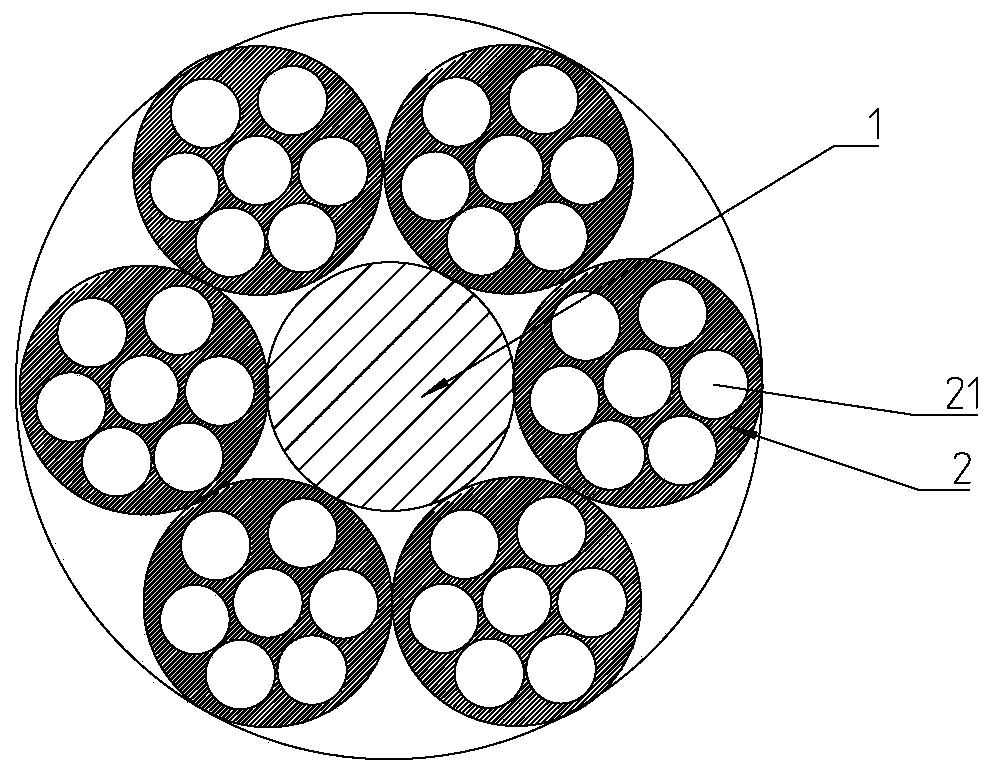

[0032] A steel wire rope for concrete prefabricated high-strength metal connectors, comprising steel wire strands 2 twisted into strands by multi-layer steel wires 21 and a mandrel 1, a set number of said steel wire strands 2 are twisted around the mandrel 1 into strands Spiral; the material of the mandrel 1 is a high-plasticity metal material, and the cross-section of the mandrel 1 is not less than one-seventh of the cross-section of the entire steel wire rope.

[0033] Specifically, the elongation of the high-plasticity metal material is not less than 30%, and its elastic modulus is much smaller than that of the steel wire twist, which makes the mandrel already produce a great deal of tension before the steel wire twist undergoes plastic deformation. Plastic deformation, when the mandrel produces plastic deformation, the steel wire rope in the bent part can maintain the bent state. Such a structure not only meets the strength requirements of the steel wire rope during the ho...

Embodiment 2

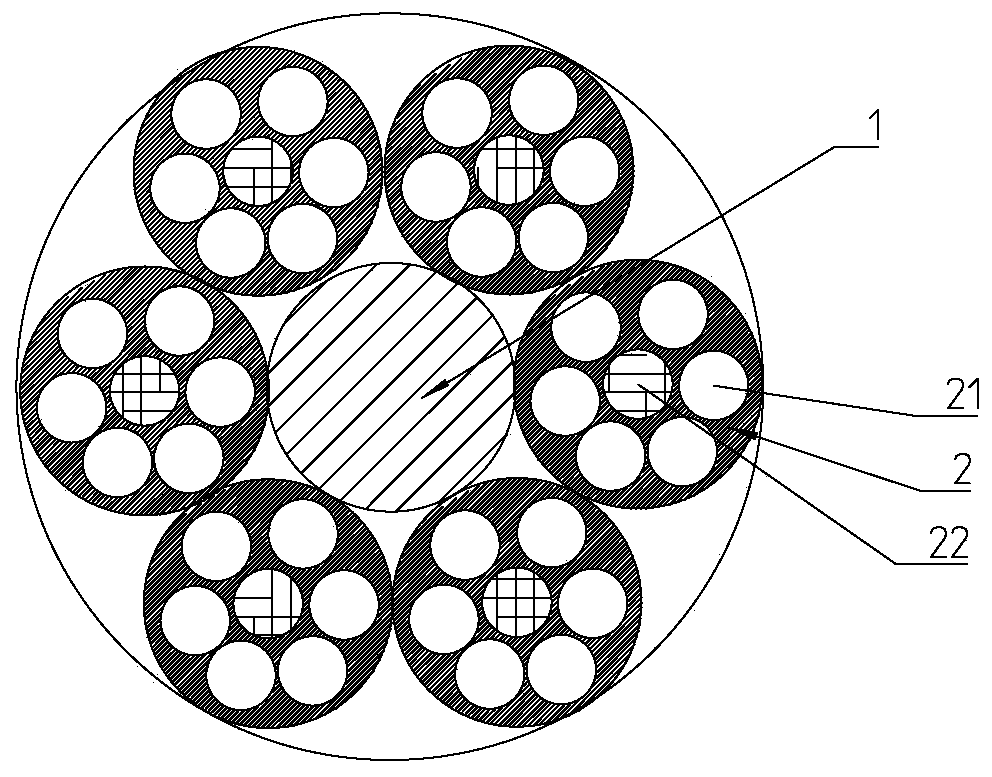

[0037] The use environment of concrete prefabricated parts is often outdoors, so the steel wire rope of the concrete prefabricated high-strength metal connector is also in the outdoor harsh environment for a long time, so there will be corrosion of the steel wire rope. In addition, during the hoisting process, the steel wire of the steel wire rope Wear and tear will also occur between them, which will affect the service life. For this reason, this embodiment also includes hemp core or cotton core 22 on the basis of embodiment one, and the hemp core or cotton core is twisted in each steel wire strand twist 2, so that in the steel wire rope The hemp core or cotton core 22 can absorb grease during the oiling process, and the steel wire stretching will squeeze out the grease adsorbed in the hemp core or cotton core 22 during use to protect and lubricate the steel wire.

Embodiment 3

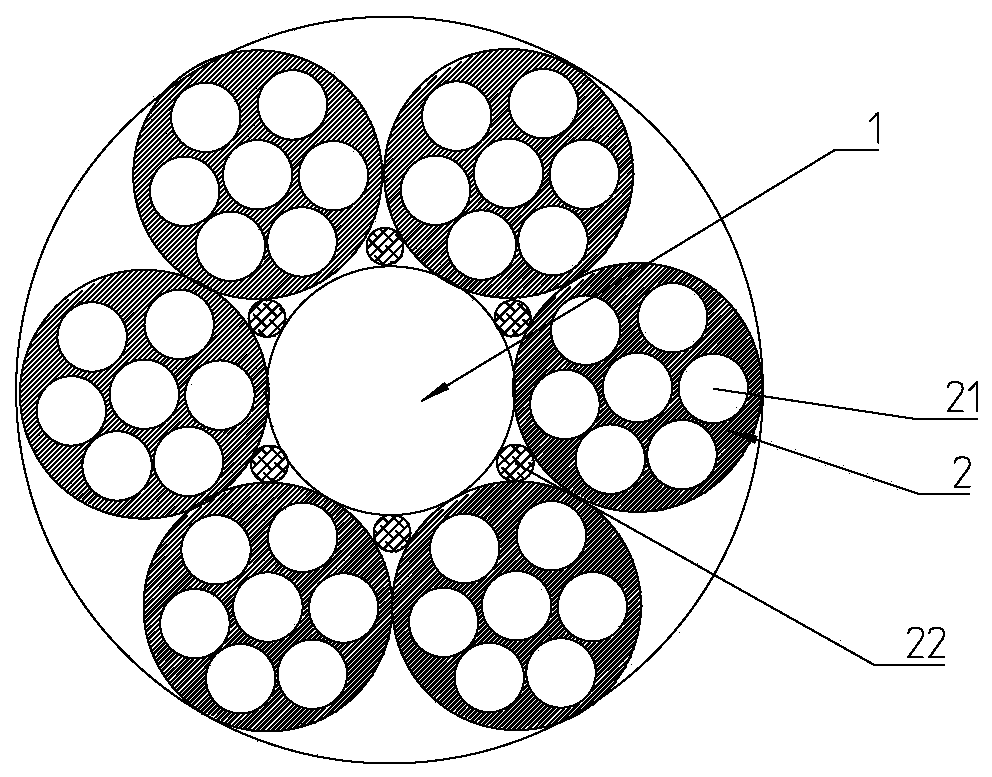

[0039] As another embodiment of Embodiment 2, its difference from Embodiment 2 is that the hemp core or cotton core 22 is parallel to the mandrel 1 and is close to the outer peripheral surface of the mandrel 1, thus solving the problems of steel wire protection and lubrication. Basically, the twisting process of the steel wire rope can be simplified.

[0040] The production method of the steel wire rope for the concrete prefabricated high-strength metal connector of the present application comprises the following steps:

[0041] S1: Purchasing semi-finished steel wire blanks and mandrel blanks from enterprises that meet national standards.

[0042] : First, the steel wire blank and the mandrel blank are pickled respectively, dried after pickling, and then drawn separately; specifically, the dried steel wire blank and the mandrel blank are drawn by a wire drawing machine, In order to increase lubrication and reduce wear during the drawing process, wire drawing powder and sapon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com