A solution recycled high wet strength paper and its preparation method

A solution regeneration, paper technology, applied in the field of paper manufacturing, can solve the problems of loss of effect, wet strength and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the solution recycled high-strength paper in this embodiment comprises the following steps:

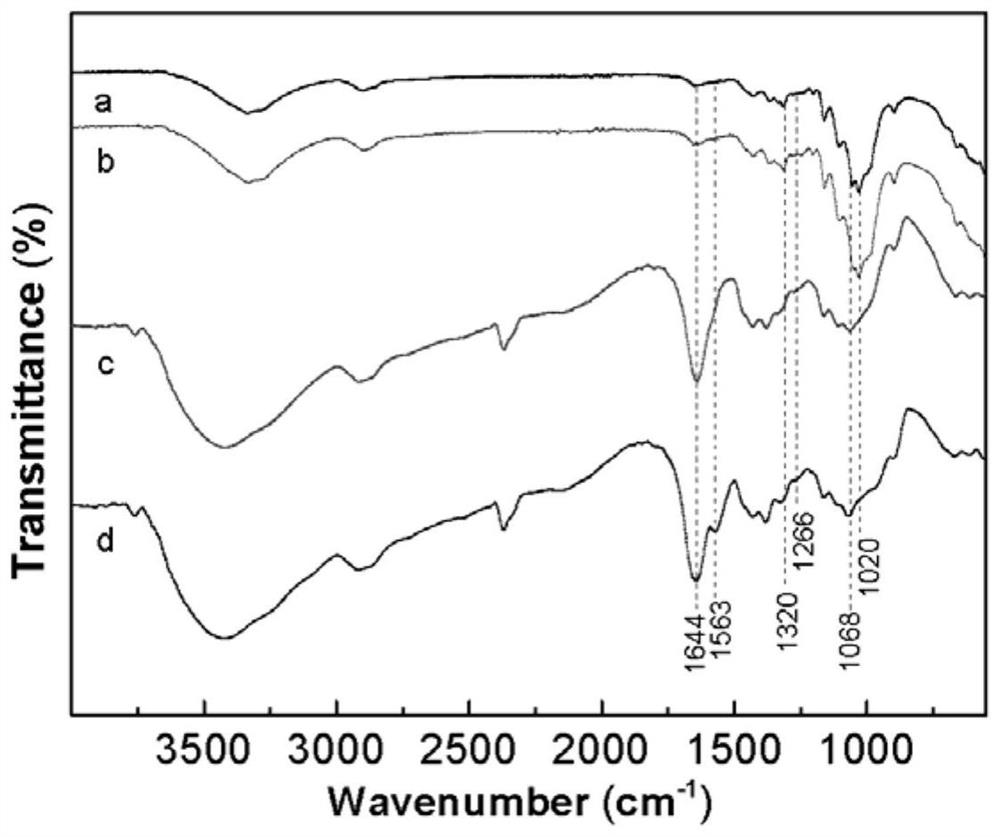

[0037] 1. Mix purified shrimp skin α-chitin with 10% potassium hydroxide / 4% urea / 86% water, freeze at -30°C, and thaw at room temperature for three times to fully dissolve to obtain a mass concentration of 1-4% α-chitin alkaline solution;

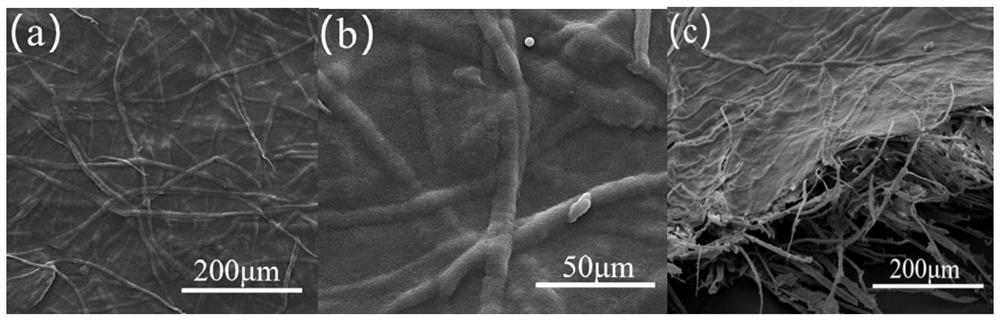

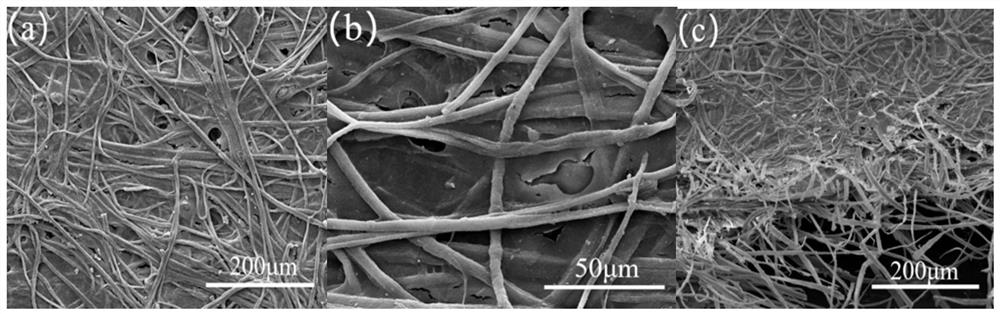

[0038] 2. Brush the above-mentioned α-chitin solution on the surface of the paper with a thickness of 0.1-0.2mm to obtain surface-sized paper;

[0039] 3. Place the above-mentioned surface-sized paper in a 90% ethanol aqueous solution bath at 0°C, regenerate it for 2 hours, and wash it with running water until neutral; obtain the surface regenerated paper;

[0040] 4. Dry the surface recycled paper naturally to obtain finished high-strength paper. Cut out 10 sample strips of 300mm×15mm from the paper and measure them with a tensile tester. The tensile strength of the paper is N.m / g.

[0041]

Embodiment 2

[0043] The preparation method of the solution recycled high-strength paper in this embodiment comprises the following steps:

[0044] 1. Mix the purified squid bone β-chitin with 16% potassium hydroxide / 4% urea / 80% water, freeze at -35°C, thaw at room temperature, and dissolve fully in three cycles to obtain squid bone β with a mass concentration of 1-2% Chitin alkali solution;

[0045] 2. Brush the above-mentioned squid bone β-chitin solution on the surface of the paper, with a thickness of 0.15 mm, to obtain surface-sized paper;

[0046] 3. Put the above-mentioned surface-sized paper in a 90% ethanol aqueous solution bath at 0°C, regenerate it for 4 hours, and wash it with running water until neutral; obtain the surface regenerated paper;

[0047] 4. Dry the surface recycled paper naturally to obtain finished high-strength paper. Cut out 10 sample strips of 300mm×15mm from the paper and measure them with a tensile tester. The tensile strength of the paper is N.m / g.

[0048...

Embodiment 3

[0050] The preparation method of the solution recycled high-strength paper in this embodiment comprises the following steps:

[0051] 1. Mix chitosan (deacetylation degree 90%) with 7% lithium hydroxide / 8% potassium hydroxide / 8% urea / 77% water, freeze at -30°C, and thaw at room temperature for three times to fully dissolve to obtain quality 1-4% chitosan alkali solution;

[0052] 2. Brush the above-mentioned chitosan alkali solution on the paper surface with a thickness of 0.1mm to obtain surface sizing paper;

[0053] 3. Put the above-mentioned surface-sized paper in a 90% ethanol aqueous solution bath at -5°C, regenerate it for 6 hours, and wash it with running water until neutral; obtain the surface regenerated paper;

[0054] 4. Dry the surface recycled paper naturally to obtain finished high-strength paper. Cut out 10 sample strips of 300mm×15mm from the paper and measure them with a tensile tester. The tensile strength of the paper is N.m / g.

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com