Dynamic variable-diameter impeller for constant-pressure pump

A constant pressure pump, variable technology, applied in the direction of pumps, pump control, pump components, etc., can solve the problem of high cost, and achieve the effect of automatically adjusting the water flow and keeping it constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

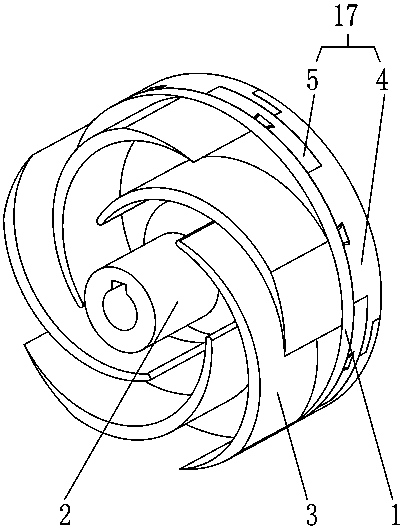

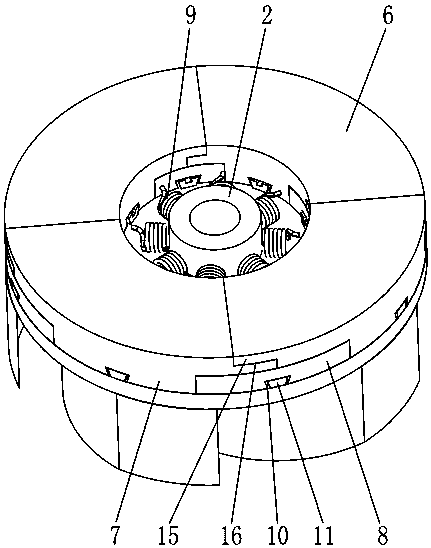

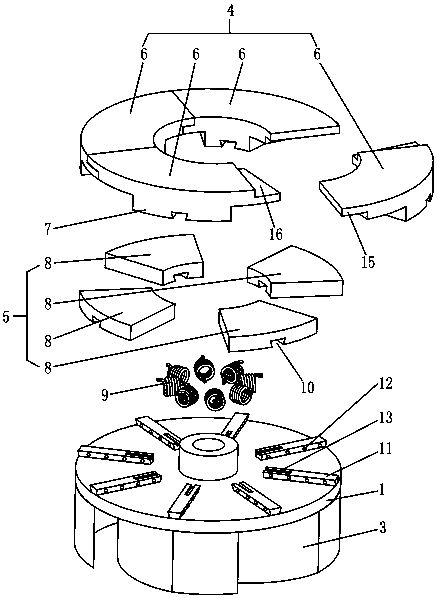

[0016] Such as Figure 1 to Figure 4 As shown, the present invention provides a dynamic variable diameter impeller for a constant pressure pump, including a wheel disc 1, a hub 2 arranged at the center of the wheel disc 1, and several blades 3 connected to one side of the wheel disc 1 and the outer peripheral surface of the hub 2 , the other side of the wheel 1 is provided with a variable diameter device, the variable diameter device 17 includes an upper end cover assembly 4 and a lower end cover assembly 5, and the upper end cover assembly 4 includes several upper fan-shaped Plate 6, the bottom surface of the upper fan-shaped plate 6 is provided with a protrusion 7; the lower end cover assembly 5 includes a number of lower fan-shaped plates 8 uniformly distributed on the circumference, and the protrusion 7 is between two adjacent lower fan-shaped plates 8 ; The upper fan-shaped plates 6 form a full circle, the lower fan-shaped plates 8 and some protrusions 7 form a full circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com