Combined type grate-fired heater

A heater, combined technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of waste heat, limited area, incomplete combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

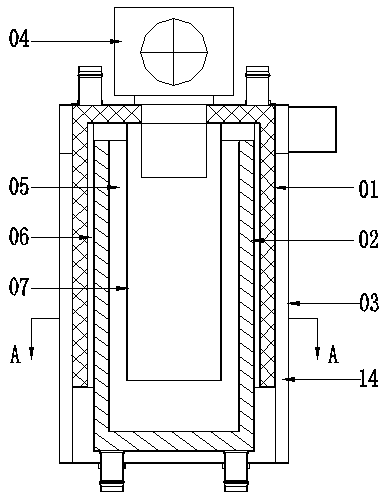

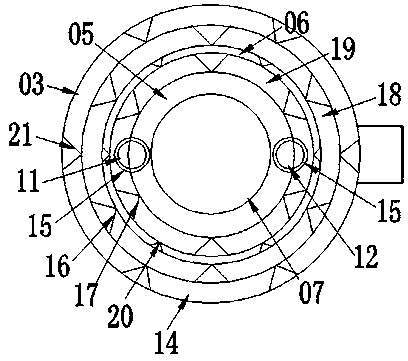

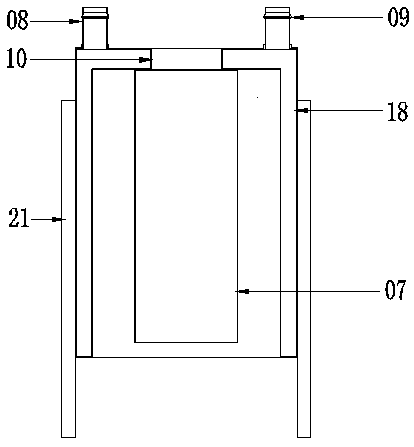

[0017] The combined stratified combustion heater of the present invention is mainly composed of an outer water jacket 01, an inner water jacket 02, a tail gas collecting shell 03, and a flamethrower 04. The outer water jacket 01 is in the shape of an open sandwich barrel. The water-jacketed barrel 18 is provided with diversion fins 16 uniformly in the interlayer of the barrel, and the outer circumference of the barrel is uniformly provided with at least 3 pieces of length beyond the barrel mouth. The longitudinal guide fin 21 of the outer water jacket 01 is provided with a burner interface 10 in the center of the bottom of the outer water jacket 01, and is equipped with a tubular combustion tube 07. The burner interface 10 and the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com