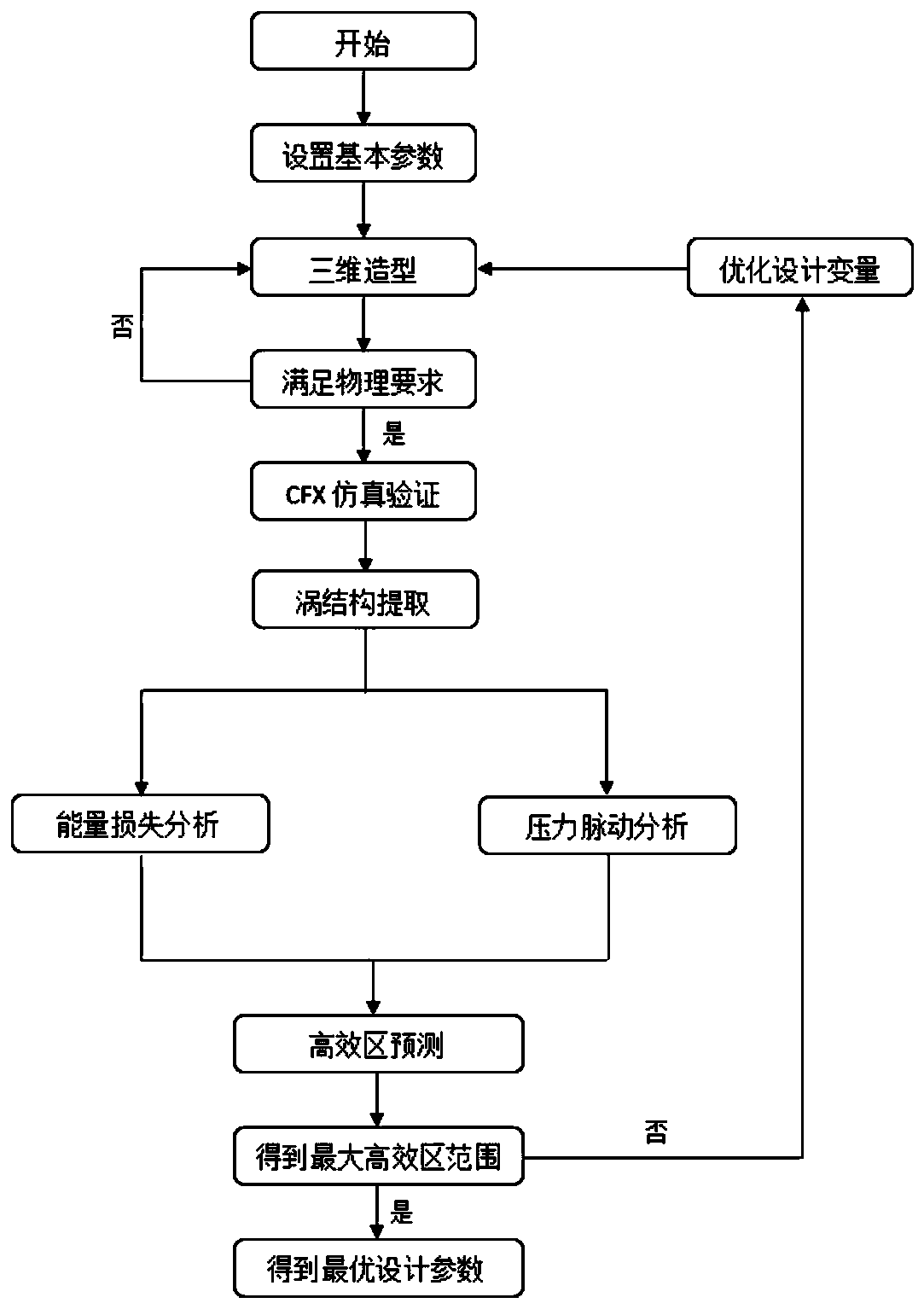

Prediction and optimization method for efficient working condition area range of centrifugal pump impeller

A technology of centrifugal pump impeller and optimization method, applied in the direction of design optimization/simulation, geometric CAD, etc., to achieve the effect of ensuring rationality and accuracy, reducing workload, and predicting accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

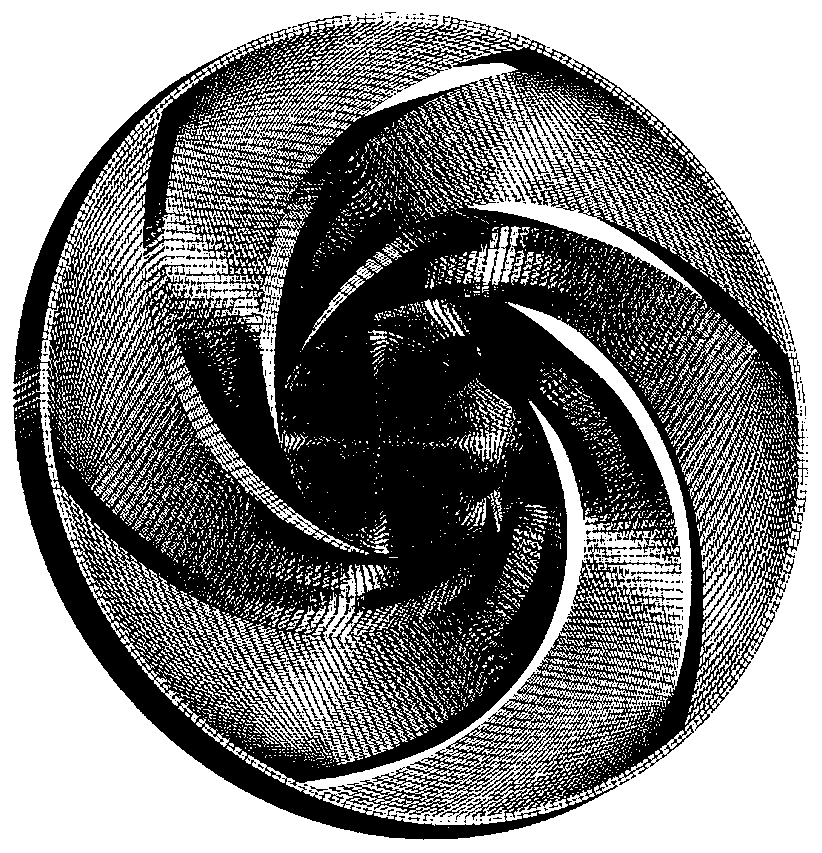

[0067] The design parameters of the original centrifugal pump impeller are the basic parameters, as shown in Table 1. Use the 3D modeling software Solidworks to model the computational domain of the centrifugal pump impeller and complete the 3D model in the ANSYS ICEM software for mesh division, as shown in figure 2 shown.

[0068] Table 1 Basic geometric parameters and performance parameters of the original impeller

[0069]

[0070] Table 2 Comparison of impeller parameters before and after optimization

[0071]

[0072] Table 3 Orthogonal optimization combination

[0073]

[0074] Table 4 Data comparison of high-efficiency working area before and after optimization

[0075]

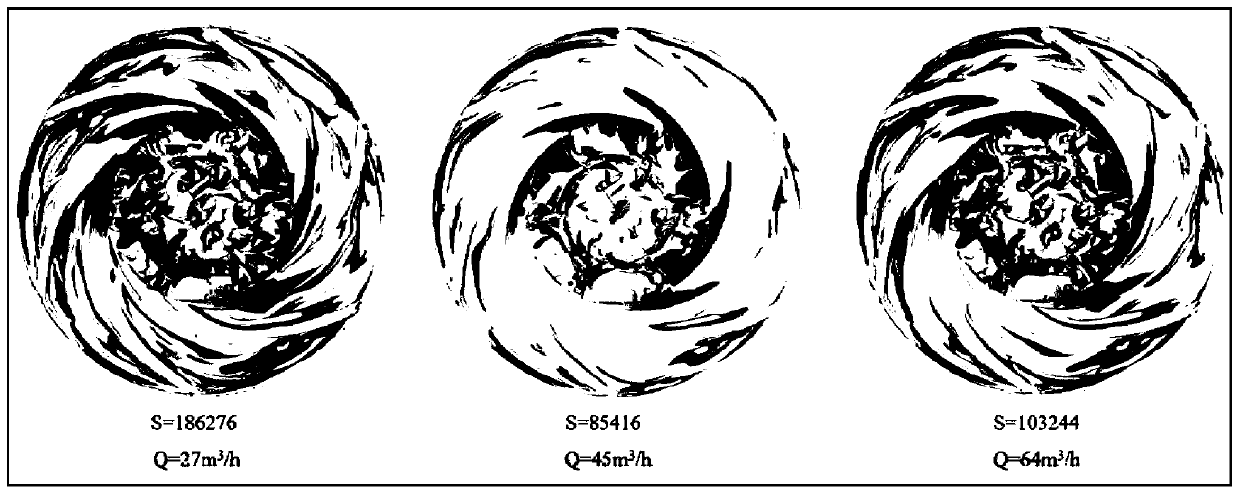

[0076] Import the calculation domain into CFX to complete numerical simulation tests under different flow rates, and obtain the vortex core surface area and pseudo-vortex core surface area in the impeller under different flow rates in CFD-POST according to the method adopted in steps 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com